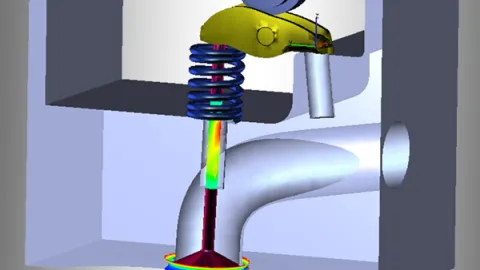

The understanding of wear phenomena is relevant for several engineering fields. Basically, every application where force is transferred between directly connected and relatively moving components is prone to wear. Such contacts are common in IC engines. While aiming for lower frictional losses in the engine it is also important to keep an eye on component durability and longevity; a challenging task due to higher specific loads as a result of downsizing. This shows that wear resistance of valve seat and guide is directly influencing the main development targets, engine efficiency and lower exhaust gas emissions. The evaluation of wear is usually based on experimental results which are only available late in the development process. Simulation models can already be adopted in early phases of engine development to predict and reduce the wear phenomenon by target-oriented measures. In this live webinar, AVL’s expert Norbert Nerpel will show how to conduct the wear analysis of the valve guide and valve seat contact using AVL EXCITE™ Power Unit. Based on a standard installation example, he will guide you through the major steps for the setup of a wear analysis and give modelling guidelines. The extent of wear is dependent on several factors, such as contact pressure in combination with relative sliding, lubrication state and material hardness. Norbert will also demonstrate how to best consider these in his presentation.