The electrification and hybridization of powertrains are ongoing efforts to meet increasingly strict global CO2 legislation. State-of-the-art test environments must be able to handle complex tasks, enabling virtual development and test execution on the testbed. Innovation, reliability, and flexibility are key success factors.

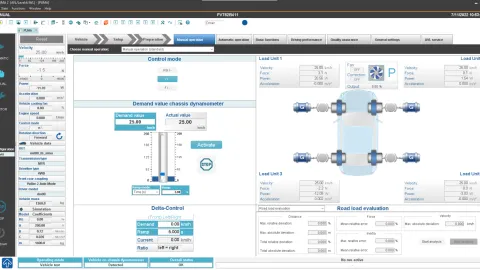

AVL PUMA 2™ represents the brains behind many different testbed applications. Our leading automation system is easily extendable to suit modern testing methods and ensures consistent and transparent testbed configuration. Our testbed monitoring and control system, AVL EMCON 6™, is completely integrated in our automation system and provides sustainable quality for your entire test field. At AVL, we offer tailored solutions for different testing environments and are continuously extending our software functionality to cover powertrain concepts such as fuel cell systems, e-motors, inverters and battery test environments, thus enabling our customers to easily adapt to present and future demands.

Data is becoming the “fuel” of the fourth industrial revolution. Without traceability, data quickly becomes useless. It is an asset which has to be accessible at anytime, anywhere, and in safe manner. AVL PUMA 2™ Share enables you to share data throughout your entire test field and centrally manages the parameters and data generated by the AVL automation system – independently of the application. Our fully integrated web-based application AVL PUMA 2™ Live displays live data from all PUMA 2 testbeds running in a PUMA 2 Share test field in a single user interface.

The automotive industry today faces many challenges that include optimizing development costs and shortening time-to-market. In this environment, it has become more important than ever to successfully execute project plans, maximize testbed utilisation and avoid useless testing. With AVL PUMA 2™ Machine Learning, we enable users to take full advantage of machine learning algorithms during their development process, saving time and costs by quickly detecting failures during online operation in PUMA 2.

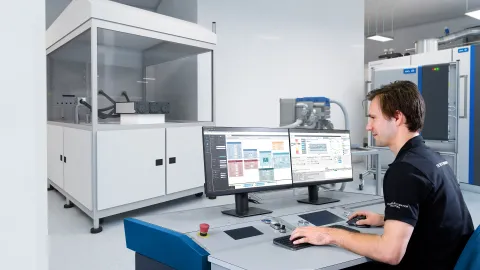

The functionality and flexibility of the PUMA 2 automation system that provides support for all types of UUTs enables us to react quickly to changing market demands.

Its deep integration in the AVL ecosystem allows us to do this very efficiently.

- Werner Faustmann, Skill Area Manager – PTE Test Factory, AVL List

AVL Test System Automation – Brochure

Tailored Software Solutions for Future-Proof Test Environments.

AVL is characterized by decades of experience and competence in the automation business. For over 45 years, we have been passionate about developing the best software solutions for our customers. Suitable for all types of testbed applications, with an outstanding usability and proven reliability. We are very proud to provide the world’s leading automation system.

>7000

testbeds installed worldwide

> 45

years experience in testbed automation, control & simulation

> 450

customers worldwide

3

expert fields: engineering, testing, simulation