The complexity of test systems and their integration into buildings is increasing, presenting new challenges for organizations. The coordination and management of interfaces across various disciplines, including electrical, mechanical, and data systems, requires specialized expertise. However, many companies are experiencing a shortage of in-house resources in these critical areas. Cost-cutting measures aimed at non-core business activities have resulted in the downsizing of departments, making it increasingly difficult for organizations to effectively manage these complex integration processes.

Brick-and-Mortar Solution

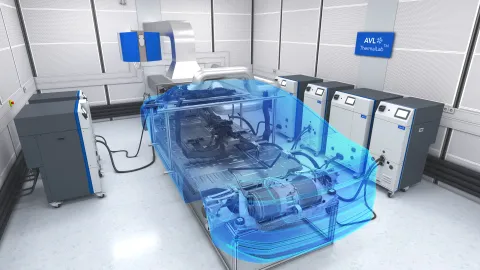

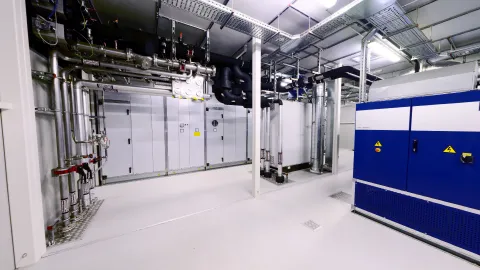

We distinguish between brick-and-mortar and modular construction projects. For brick-and-mortar projects, which are traditionally constructed on-site using concrete methods, our focus is on providing state-of-the-art measurement and testing technology. In addition, we provide essential building services directly tied to the project and offer comprehensive conceptual planning for the entire construction process. Depending on the specific needs and market conditions of our clients, we also have the capability to deliver the physical building itself.

AVL Tech Center Modules

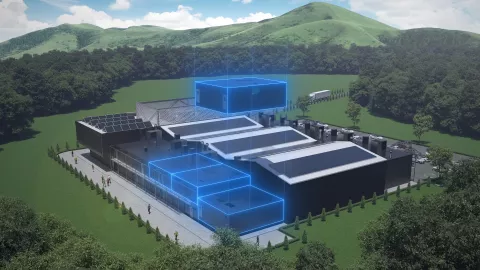

Our modular construction projects feature prefabricated modules, including containers, that are meticulously pre-assembled at our facilities. Each module is equipped with integrated mechanical, electrical, and plumbing (MEP) systems, as well as measurement and testing technology. Delivered to the end customer as a complete, ready-to-use module, our approach significantly accelerates the construction process. By shifting interface risks from the construction site to our controlled environment, we ensure risk reduction and enhance project efficiency.

A hybrid solution between brick-and-mortar and prefabricated testbed modules is also possible. A building of limited complexity and cost is constructed and the modules are moved into it. The media facilities can either be part of the modules or centrally located. The building is sometimes equipped with the planned number and types of testbeds from the start, or alternatively, it is started with a limited number of testbeds and expanded over time as the test needs grow.

The AVL Tech Center Solutions offers and executes projects with a holistic view of the entire scope. We combine various test systems and find the best way to size our customer's facility - as large as necessary, as small as possible, to create the best solution.”

– Andreas Bohmann, Solution Engineer, AVL List GmbH

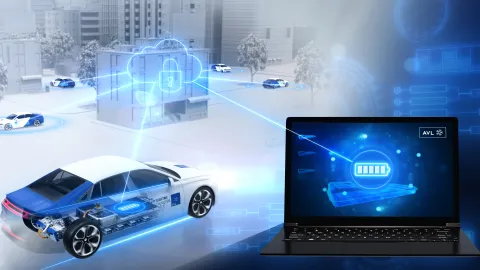

We have in-depth knowledge of testbed operations, tech center planning, and especially MEP component sizing. This allows us to design and build testbeds that meet specific needs at a low investment cost. It also enables us to evaluate the requirements of individual components in terms of the overall result. This ensures that the originally formulated overarching requirement for the tech center is broken down to the individual systems and finally aggregated again when the overall system is integrated.

Benefits at a Glance

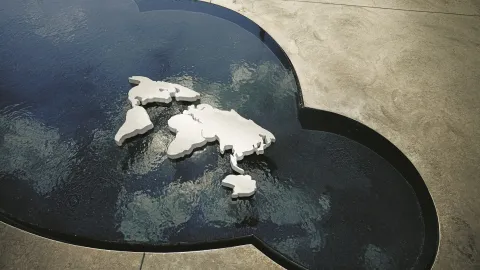

- Global network of facility engineers covering all standards for the relevant markets.

- Global service network providing full service for maintenance and repair of Tech Centers, including MEP components.

- In-house developed virtual reality solutions for design review of building concepts.

- In-house developed augmented reality solutions for maintenance and training activities.

We have facility design engineers in seven locations worldwide. With powertrain engineering also located around the world, we always have an up-to-date, in-depth understanding of current market developments, which we incorporate into the local facility design.

> 1,000

testbeds with AVL facility design.

> 400

Tech Center Modules delivered.

> 100

specialized staff globally.