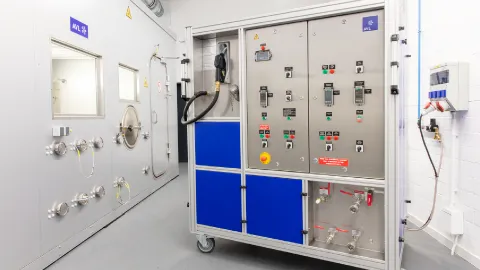

AVL FUELLOAD was designed with the latest US and China certification regulations in mind. The fully self-sufficient system for fuel preparation and refueling is mobile and was specially developed for ORVR refueling tests. Optional extensions allow AVL FUELLOAD to be customized to the desired application.

ISO 17025 Calibration

With the optional ISO 17025 compliant calibration, a maintenance concept is available for the AVL FUELLOAD refueling system, which also meets the requirements for vehicle type certification.

Suitable for R&D testing

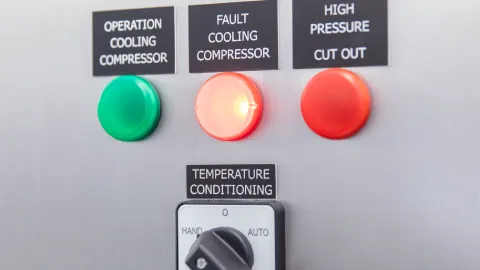

With its high-precision temperature and flow control, the system exceeds current legal requirements making it the ideal system for R&D purposes or future requirements.

Efficient test operation

The high temperature control capacity and reliable fuel preconditioning of the device allows for shorter preparation times and thus efficient test operation.

- Complies with current legislations US/EPA (§86.154-98) and China 6 (GB/T 18352.6)

- Large, continuously adjustable temperature range (5°C –55°C)

- Large, continuously adjustable Flaw range (3 l/min –50 l/min)

- Precise temperature control with an accuracy of < +-0,5 °C

- Precise flow control with an accuracy of < +-0,3 l/min

- High heating capacity (> 1 K/min)

- High cooling capacity (> 1,2 K/min)

- Precise fuel quantity measurement with less than 0.3 % deviation

- Internal tank with a volume of 200 liters (usable range: 20-180 l)

- Supports gasoline (EN228), diesel fuel (EN590), ethanol (E85), methanol (M15), biofuel blends and other alternative fuels.

| Property | Unit |

|

Tank volume |

200 l |

| Flow range | 3 – 50 l/min |

| Temperature range | 10 – 55°C |

| Interfaces | LAN/TCPIP; analog interface (option) |

| Compressed air specification | 6 bar (continuous base), oil- and water-free |

| Certification | ATEX, TÜV, CE |

| Dimensions | 1980 x 1600 x 1100 mm (W x D x H) |

Wide Range of Applications

A wide range of applications is covered: from conventional use of ORVR tests to use for research and development purposes.

Powerful Automation

All data acquired during test operation is stored centrally, processed and logged via our AVL SHEDCON automation software.

Regulation Compliance

AVL FUELLOAD is designed for certification testing in compliance with the latest EPA, CARB and China 6 certification regulations.

Industrial Design

The system is designed for operation in potentially explosive atmospheres (ATEX Zone 1). The pressurized control cabinet of the refueling system prevents the ingress of explosive atmospheres.

Unmanned Operation

The system was designed to operate unattended and continuously supported by a fully automated data acquisition system, self-diagnostic functions and integrated safety modules.

Wide Range of Fuels

Various fuels, such as gasoline, diesel, ethanol, methanol, biofuel blends and other alternative fuels are supported. This makes AVL FUELLOAD a future-proof system equipped for future requirements.

Active Vapor Recovery

In addition to the conventional use as a refueling device in accordance with the EU standard, the optional "active vapor recovery" option absorbs harmful hydrocarbon vapors and thus also enables refueling operations in accordance with the European standard.

Easy Exchange of Nozzles

With the DryLink mechanism - a patented, drip-free quick coupling system - a fast and drip-free exchange of the nozzles is possible.

Precise Temperature and Flow Control

With its high-precision temperature and flow control, the system exceeds the current legal requirements and is therefore also ideally suited for R&D purposes as well as future requirements.

Mobile Use

The system can be operated either manually on the device or - via an integrated network interface - with the AVL "SHEDCon" automation software. An optionally available, explosion-proof tablet PC allows the system to be used regardless of location.

Solution Sheet Evaporative Emission Testing

Learn more about portfolio of products for evaporative emission testing.