24/7 Safety

When it comes to battery electric vehicles (BEV), round-the-clock passive safety is a key customer requirement. To meet this demand, manufacturers are faced with the challenge of developing no-propagation battery designs. This requires a detailed, thorough development and verification process, which AVL’s simulation methods provide in full.

Rapid Charging

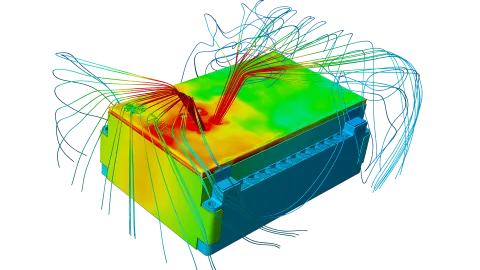

A major challenge when it comes to charging batteries faster is cooling the cells and modules effectively. Innovative cooling concepts allow for significantly reduced charging times of electric vehicles. Our simulation solutions for thermal performance make a valuable contribution in this area – optimizing specific oils as coolants is one example of how they do this.

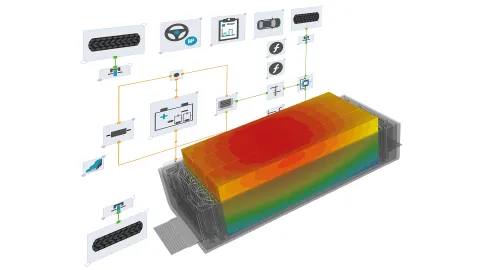

Most manufacturers are already using engineering simulations to develop batteries. However, the models for this utilize a simplistic setup of framework conditions that is to be used to develop a specific property or functionality of the battery.

This procedure is not sufficiently conclusive for us at AVL. Which is why we use the much more complex method of virtual validation instead. We have the broadest spectrum of options in this area, which extends as far as a fully virtual validation environment, including all relevant influencing factors. This is because the only way to draw reliable conclusions about the behavior of batteries is to consider all framework conditions.

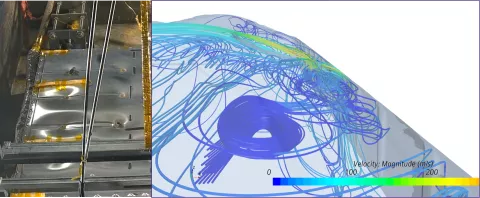

That is why we perform almost all our tests as virtual validations – for example, fuel fire tests. Here we not only simulate the heat of the fire, we also simulate its gas dynamics. Sometimes this can result in the battery catching fire much sooner than you would expect by simply looking at the temperature emitted from the flames.

Reliable Safety

All roads lead to AVL when it comes to achieving no-propagation targets. Our virtual validation facilitates battery designs that ensure no thermal runaway between cells can occur even over several hours under toughest conditions. We thereby more than meet the statutory guideline values.

Innovative Cooling

Special oils – the evaporating temperature of which can be designed exactly – are used to cool the battery with very effective two-phase cooling. Our simulations provide precise solutions for the specification of such oils, and for the layout of the evaporation surfaces and the related thermal system. Our customers in this sector include some of the most renowned oil manufacturers in the world.

Reliable Calibration

To calibrate our simulation models with the correct parameters, we run our own Battery Safety Center in cooperation with Graz University of Technology. The center has separate testbeds for all requirements – for example, for the complex issue of thermal runaway. We also maintain our own laboratory, in which we are able to fully parameterize materials; for example, the adhesives used in batteries.

Comprehensive Co-Simulation

For the integration of battery cells, we consider the interaction of the processes in the battery. This is because phenomena such as swelling and breathing have mechanical as well as thermal and electrical consequences. Therefore, coupling the simulations is key for us. For example, for thermal runaway analyses, we link various models: thermal flow, gas flow, particle distribution, mechanical deformation, material melting, arcing, short circuit calculation, and so on. This extent of co-simulation makes AVL unique on the market.

AVL Software

At AVL, we develop the software products required for battery simulation ourselves. You can purchase well-known programs such as AVL CRUISE™ M, AVL FIRE™ M, and many other proven AVL tools from us and integrate them into your processes directly. You can also use our software as part of our services. If you have particular requirements, we set up and provide tailored toolchains for you

Design Analyses

Our simulation models investigate all characteristics and all interactions of your existing battery design. We provide you with a detailed report of the results.

Design Proposals

Based on the design analysis, we devise specific optimization suggestions for you. In doing so, we break down the exact details of the improvements and which modifications are needed to achieve them.

Concepts for New Variants

When developing and enhancing batteries and appropriate derivates, we devise new design proposals for you, based on our virtual models. This enables you to implement your development goals optimally.

Validation

You can use our virtual validation to secure your battery design for the final model for series production (design freeze). In addition to “pass” or “fail”, our assessment also contains specific details on why a test was not passed.

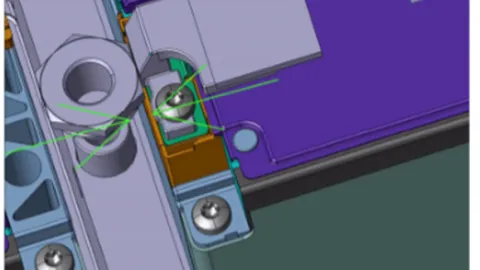

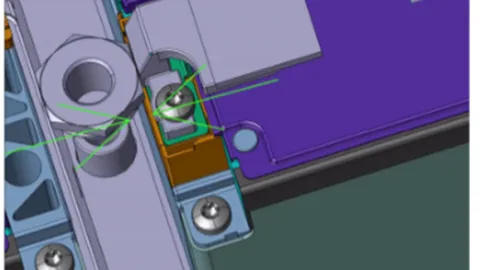

The optimum packaging of cells is incredibly important with regard to swelling and breathing in particular – two phenomena that occur in every battery. Safe integration is crucial, especially in terms of fast-charging capability.

– Bernhard Brunnsteiner, Skill Team Leader Battery Cell, System & Functions

Related Topics

We are constantly working on new solutions. The following might be interesting for you: