Hydrogen technology provides answers to many pressing challenges in the automotive industry – primarily to the call for more emission reductions. At the same time, however, the development of powerful PEM stacks brings with it its own obstacles for providers and users:

- High power density is just as important as long durability – and the two goals are conflicting.

- Particularly high lifetimes must be guaranteed for heavy-duty applications – expectations are fueled by the performance values of diesel technology.

- The supply chain for PEM stacks is still evolving. Some components are currently only available from a single source.

- This is a major contributing factor to the technology currently being very expensive still – from the individual component all the way to the entire stack.

- Consequently, high efficiency is essential to remaining competitive in terms of total cost of ownership (TCO).

You get the full package of engineering and design services from us: We develop stacks and integrate them into fuel cell systems, powertrains, and even vehicles. Our approach includes:

-

Design, integration, simulation, and testing of PEM stacks – development from the very beginning to series-production readiness

-

Design platform Gen1 as foundation for development – with even more efficient use of space at cell level and thus dramatically improved power density compared to Gen0

-

Creation of stack architectures for customer-specific applications

-

Modeling of stack power to analyze conflicting goals at system level early on

-

Concept and optimization of single cells

-

Provision of benchmarking and material selection for stack components

-

Build-up, testing, and analysis of prototypes (a small number)

-

Partnership for production-ready development of any volume

-

Global supply base

We are your independent engineering service provider with extensive experience in the development of PEM fuel cells. With our expertise in vehicle development and system integration, we offer you the following advantages:

Reduced Development Effort

For the PEM stack design, we have developed design platforms that you can build on – an enormous time and cost saving when industrializing your PEM stacks.

Technological Competitive Edge

With our support, you get a PEM stack with market-leading KPIs: power density, efficiency, durability. We have the right technical solutions for you in all these areas, including for system integration.

Tailored and Cost-efficient

You get the PEM stack design you want – right from the start. We can adapt our existing stack technology, which has been tried and tested multiple times, to suit your specific requirements. The advantage for you is significant time and cost savings.

Always the Best Suppliers

Despite the somewhat small supplier landscape for PEM stacks – for example, for bipolar plates – we have a solid supplier base. We would be happy to advise you on which components from which source are most suitable for your application.

Real Net Output Ratio

The standard market purchase price for a PEM stack accounts for around 60 % of the costs of the powertrain. If you develop the stack in-house with our support instead, you bring a huge real net output ratio to your company.

In the Silicon Valley of Stack Development

Thanks to our tech center in Vancouver/Canada we are well connected to the technological stronghold of PEM stack development.

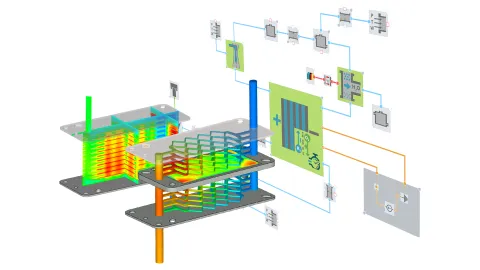

Stack Design with Expertise

An essential part of our stack development consists of precise simulations that move important process steps forward in time. In the same way you are used to from us with internal combustion engines (ICE) and hybrid drives.

We know how to devise a Design Verification Plan (DVP), and combine this knowledge with the fuel cell expertise that we have in our company. We are now applying our many years of experience in the classic disciplines such as electrics and electronics (E/E), system development, design, and construction to your PEM fuel cell stack.

Operating Strategy

The scope of delivery of our stack developments always includes the operating strategy. We thereby optimize many parameters, such as power requirements and system temperature, as well as the influence of humidity and outside temperature on the fuel cell. A crucial step to avoid degradation and maximize the lifetime of your system.

Digital Twin

You will receive a 1:1 digital model of your stack. We create the physical models contained therein for aging prediction together with market leaders in this field. This enables you to predict damage reliably.

Validation and Testing

We validate and verify your PEM stack up to the release recommendation for series. For this we have the proven methodology (DVP) as well as the state-of-the-art testing equipment at our global test centers.

Related Topics

We are constantly working on new solutions. The following might be interesting for you: