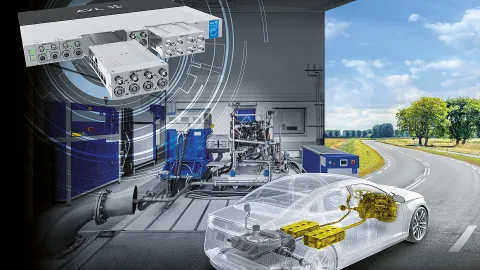

Ever more stringent emissions targets force the automotive industry into using increasingly complex combustion technology: The combination of electrification and advanced combustion solutions provides the key elements of clean and efficient propulsion. As this increase in complexity results in increased effort in powertrain development, robust and thorough analysis methods become mandatory.

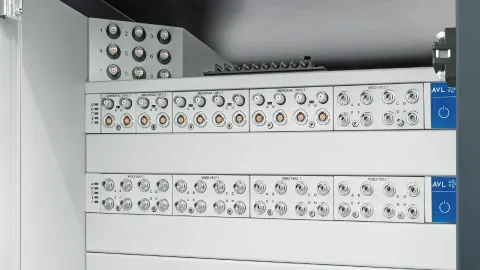

With these challenges in mind, AVL has developed AVL X-ion, the new high-speed data acquisition platform dedicated to powertrain development. AVL X-ion is a modular acquisition system that can be easily adapted to different units under test and test environments. It combines AVL’s know-how and expertise in several application areas, namely indicating, optical combustion analysis, NVH and e-power analysis.

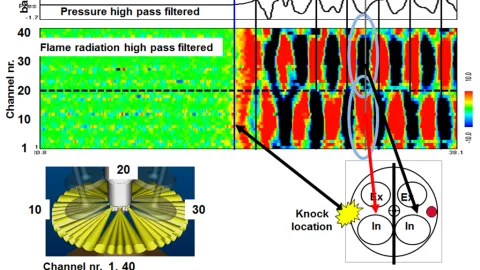

The data collected is analyzed in the AVL IndiCom 2™ software with specific Visio application packages, along with cylinder pressure data. Combined with real-time calculations and trigger data, the platform provides a detailed understanding of dynamic combustion scenarios.

X-ion enables crank angle-based in-cylinder flame radiation measurement. This facilitates the identification of soot particle formation in both stationary and transient engine states.

Sporadic or irregular self-ignition events are detected and localized by combining X-ion’s cylinder pressure with flame detection routines. With such an array of features, X-ion is a powerful and versatile powertrain development tool.

|

|||||||||||||||||

Analysis of Combustion Scenarios

The platform AVL X-ion in combination with real-time calculations and trigger data provides detailed understanding of dynamic combustion.

Visualisation of Flame Phenomena

The system’s high sensitivity in combination with a high dynamic range of the photodiodes allows the measurement of varied flame phenomena in spark ignited engines.

Identification of Soot Particle Formation

With crank angle-based in-cylinder flame radiation measurement, AVL X-ion enables the identification of soot particle formation in stationary and transient engine states.

X-FEM VISIO V8X2

The X-FEM VISIO V8X2 is an eight-channel optoelectronic photodiode signal converter module for test bed and in-vehicle operation.

High-Precision Photodiodes

High-precision photodiodes combined with 24-bit ADC provide high signal quality and can manage 32 light-signals per base unit. In-cylinder combustion events can be analyzed using Visio spark plugs.

80 Channel System

Up to ten modules can be combined to an 80-channel system for knock, pre-ignition and particulate emissions applications. It is the ideal solution for the optical measurement of any highly dynamic phenomenon on gasoline engines.

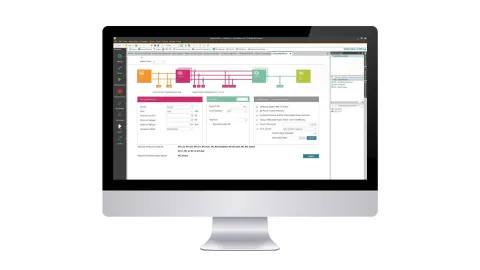

VISIO Application Software

Software packages are available for the flame propagation, knock analysis, particle analysis and pre-ignition VISIO applications. The software is used in combination with a Visio spark plug sensor with up to 8, 40 channels or 80 channels.

AVL VisioScope

VisioScope makes optical recordings of the level of carbonization, fuel injection, soot formation and temperature distribution. This is achieved with an endoscope and camera.

VISIO Service

AVL not only sells products from the Visiolution product line, we also offer measurement services and data evaluation for AVL optical measurement equipment.

Solution Sheet X-FEM Visio

Particle Sources in Drive Tests

Particle Sources in High Resolution

Catalyst Thermoshock

Flame Analysis

Developing GDI Engines

Irregular Combustion Events RDE

Whitepaper Hybrid Electric Vehicles

Powertrain diagnostics in hybrid electric vehicles