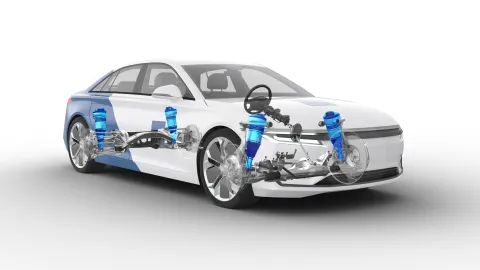

The ongoing electrification offers huge potential for optimizing chassis way beyond the limits of classic mechanics. At the same time, customer demands regarding dynamics, comfort, and safety are growing.

Choosing the Right Technology

The possibilities offered by electromechanics enable desired driving characteristics to be achieved in a variety of ways these days. Manufacturers are required to find the technical solution that best meets their performance and efficiency targets.

Seamless Integration

Suspension systems are becoming increasingly complex and have a variety of interactions with other subsystems (e.g., steering and braking). In addition to the right interface technology, seamless integration primarily requires a target-oriented development approach for the overall system.

Cost-Saving Scalability

Since engine versions and axle loads often vary greatly within a model range, the design scalability of wheel suspensions is extremely challenging for many manufacturers. The solution is a smart common parts and modular system for suspension systems, which can be installed in various vehicle derivatives or even across different model ranges to meet specific requirements.

A Central Control Unit

The trend is moving away from individual control units toward a high-performance central control unit for propulsion and chassis. In addition to increased software complexity, this also involves new requirements at component level. For example, the sensors need to deliver sufficiently good signal quality to be used simultaneously for steering, braking, suspension, and driving comfort modules.

The Precise Objective

Different markets sometimes also have different requirements in terms of driving dynamics, suspension comfort, chassis height, and load limit for the same vehicle models. This spectrum must be identified using upstream benchmarking and the property target definitions must be derived for all vehicle derivatives.

When designing driving characteristics, at AVL we always consider the overall vehicle concept first. To do so, we use our systems engineering approach, from target definition and system design – including the definition of desired functions, necessary requirements, and specifications – through to successful integration and validation.

Another area of focus is the chassis mechanics. Our development goal here is to achieve a mechanically well-balanced chassis. The kinematic properties need to meet the highest possible quality and stability targets even without mechatronic support. This is the basis for using software-controlled, mechatronic systems to further optimize the desired driving dynamics properties.

At AVL, we support you with tailored solutions for efficient and successful development, optimization, and integration of state-of-the-art chassis systems and mechanisms, as well as electromechanical components.

We Offer Experience and Expertise

AVL has a wealth of engineering experience and a team with in-depth chassis knowledge. Numerous references testify to our skills – from the design of suspension systems and their construction and integration into new vehicle types or derivatives, through to software control and control unit development of active chassis functions.

We Give You Maximum Flexibility

You do not have to commission a full chassis package at AVL – unlike many of our competitors, we also support you with individual chassis functions and their integration with the release of the corresponding interfaces

We Simulate Chassis Functions

One of AVL’s core competencies is virtual development and validation to maximize frontloading. This saves you valuable development time and requires fewer prototypes. With our virtual development approach that comprises hardware-in-the-loop, software-in-the-loop, and driver-in-the-loop solutions, we maximize maturity at the earliest opportunity, for example, through pre-calibration and functional safety tests in the virtual development environment.

We Test and Validate

The ZalaZONE in the west of Hungary operated by AVL is a 250-hectare vehicle proving ground for electric and conventional vehicles. This is where we perform testing that includes stability and dynamics tests and prove that our and your software and hardware solutions function as expected.

We Are Where You Are

No matter whether you are developing a suspension system or a chassis function for a market in a specific version or require an entire portfolio worldwide in various versions – with our presence in Europe, the US, and Asia, we cover all relevant markets from a single source.

We Focus Entirely on Your Needs

We can also provide you with software controls for electromechanical actuators in the suspension system (e.g., active stabilizers, highly integrated spring-damper units, and much more) as a white box solution, which you can further develop in collaboration with us or independently. On request, we can even grant you IP exclusivity for your project.

Mechanical Components/Systems Engineering

We take care of the development of a mechanically balanced suspension system with all necessary components for you.

Software and Function Development

Based on our systems engineering approach, we develop and optimize your choice of specific chassis functions.

Benchmarking and Target Setting

We objectify and evaluate your desired driving characteristics and use these as a basis to clearly define targets.

Integration and Interaction

We guarantee the functional, geometric, and mechanical integration of the chassis system with all its components into the overall vehicle – for superb driving characteristics.