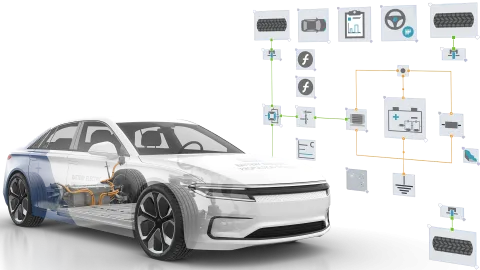

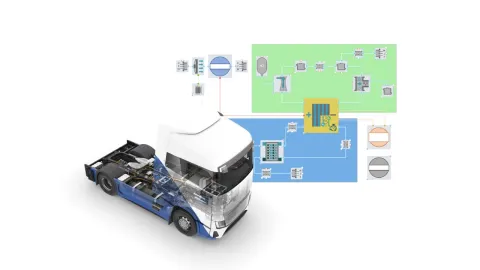

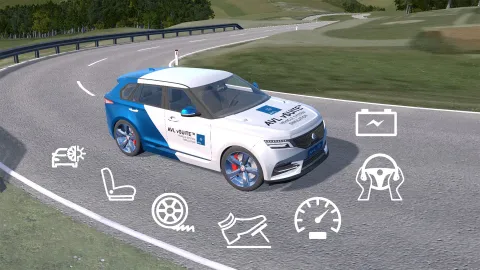

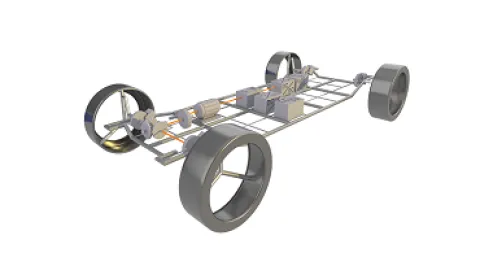

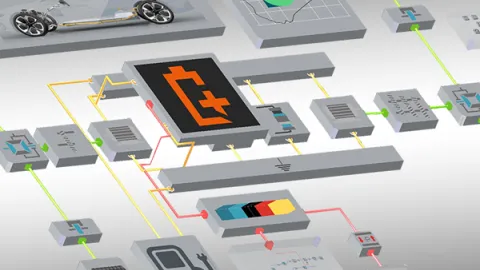

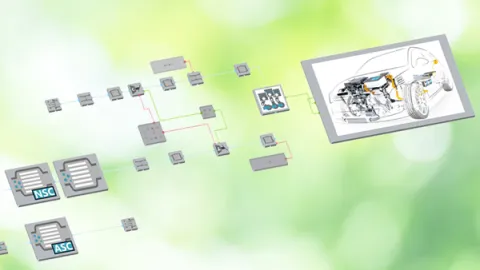

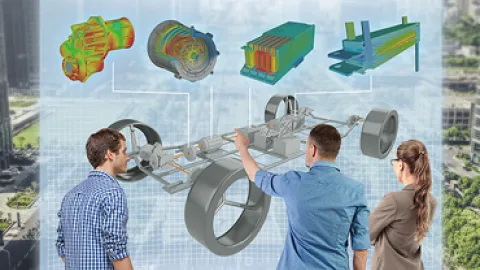

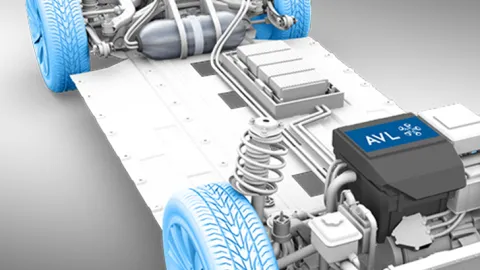

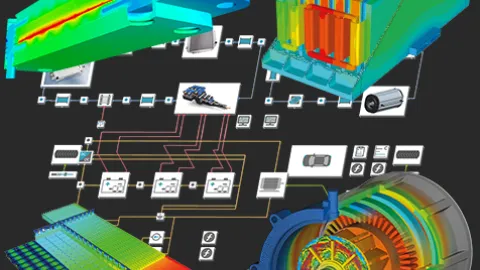

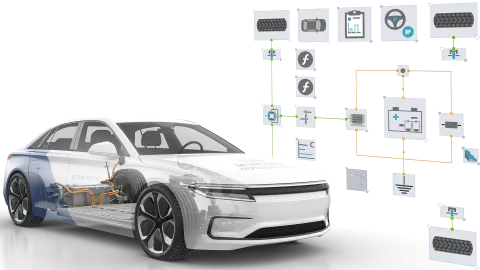

In order to achieve the set vehicle targets, a suitable system must be developed. Due to the large number of variants and combinations of vehicle components and their interaction, vehicle development is a complex optimization task. Concept studies help to avoid late and costly changes from the outset.

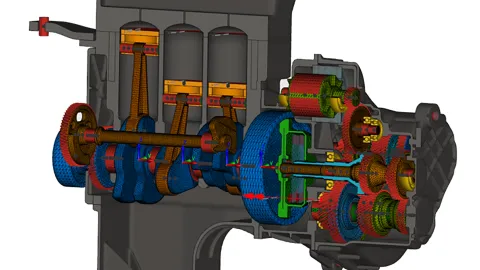

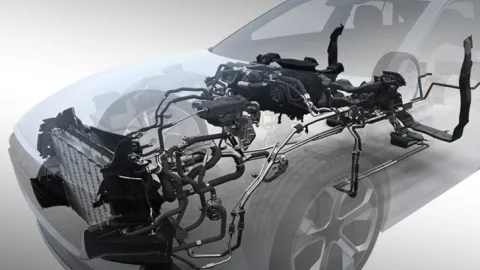

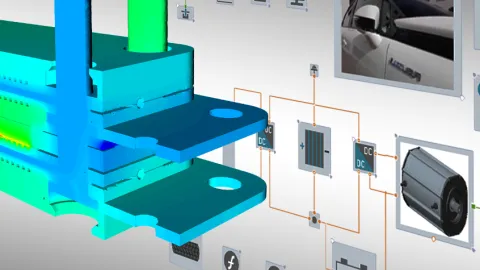

In the case of battery electric vehicles, for example, questions about the battery pack and cells as well as the type of thermal management have to be answered. In addition, requirements for the electric motors, their coordination with the transmission and the operating strategies must be clarified.

Model Parameterization

Easy-to-parameterize models with high prediction quality for performing concept studies

Scaling of the Model Depth

Studying the interrelationship between the different domains in the course of the development process

Real-Time Capable Models

Calibration of controls using virtual models in a Mil/HiL/SiL environment

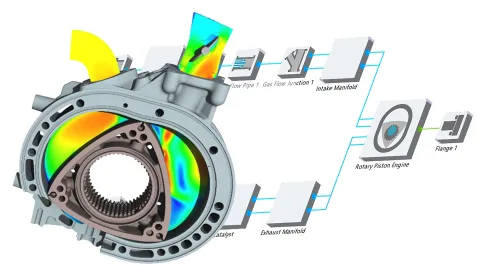

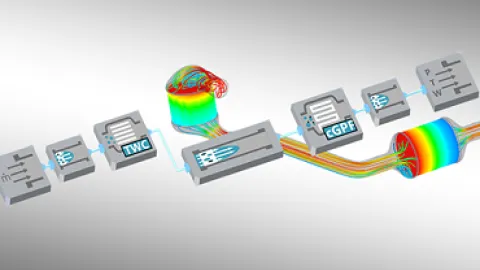

Reliable and Fast Calculation Methods

As a starting point for detailed 3D simulations to evaluate requirements such as performance, size, etc. for individual components

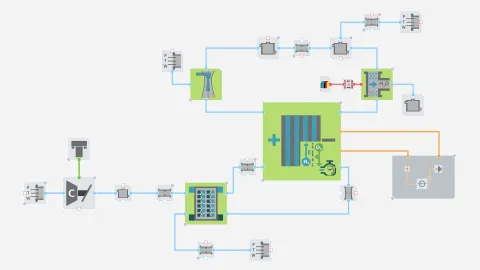

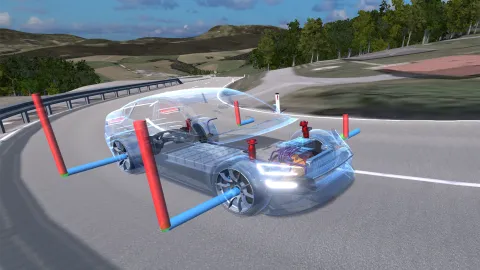

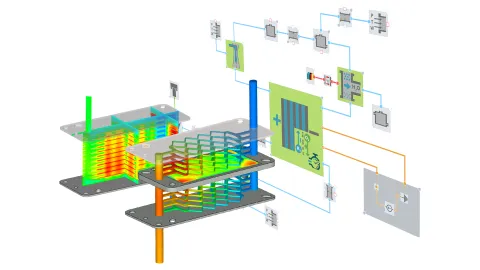

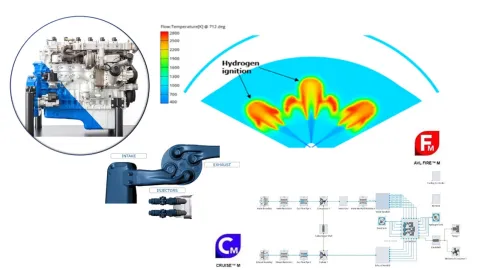

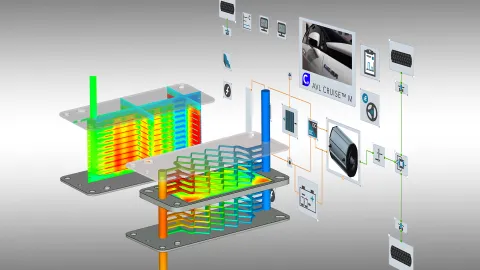

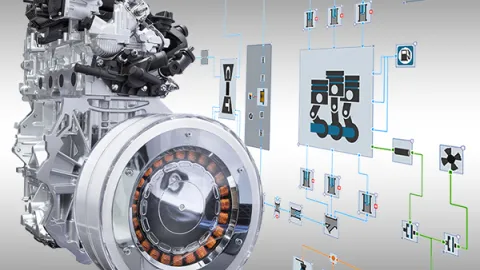

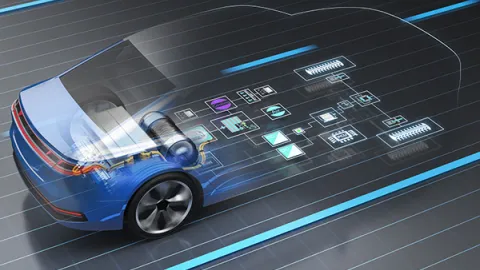

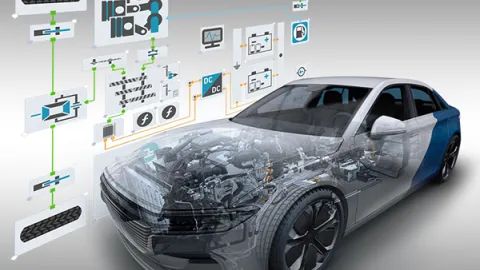

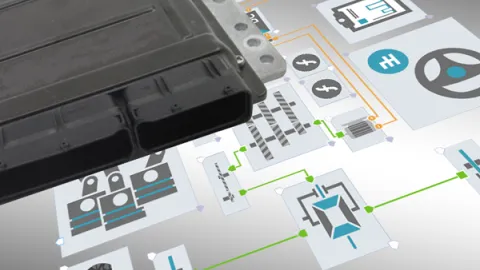

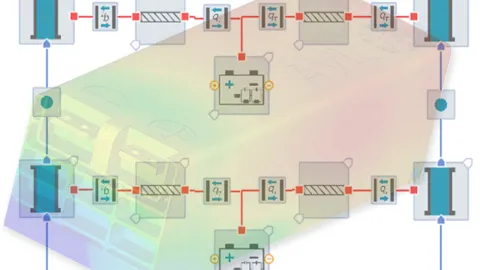

CRUISE M models all relevant physical areas that occur in a vehicle. These include electrical networks, thermoregulation systems including air-conditioning circuits, mechanical and thermodynamic systems, and a generic data and function network for control tasks. In these networks, the software models complex reaction chemistry for electrochemical processes, heterogeneous catalysis, or homogeneous gas reactions.

This allows you to design and optimize both subsystems and the overall system in a network in detail.

Real-Time Capability

The dialog between models and real components on the virtual testbed takes place in milliseconds. This is the range in which CRUISE M realistically predicts the behavior of the virtual components.

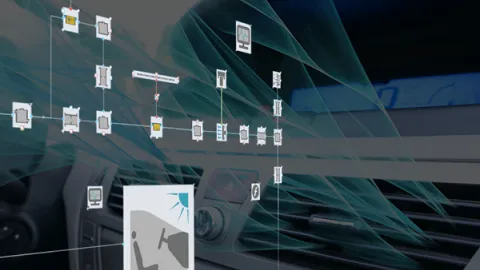

Cross-Process and Compatible

CRUISE M models support you in your entire engineering process. Standardized interfaces such as FMI allow models created in other modeling environments to be easily coupled and simulated as part of an overall CRUISE M model.

Time and Cost Savings

Simulation is a way to answer many questions right at the beginning of the development and thus to get on the right track early. In any case, CRUISE M can be easily integrated into your existing development environment.

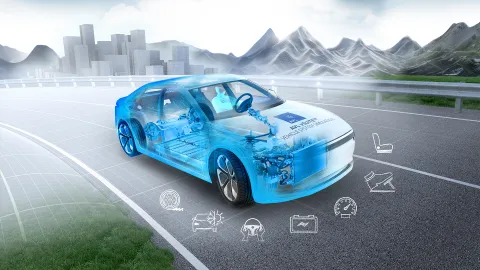

Validated Vehicle Models – Versatile Development Aids

The AVL database currently includes more than 300 validated models of vehicles with a range of drive concepts – from conventional internal combustion engines to hybrid concepts and battery-powered and fuel-cell-driven vehicles. For example, there are validated AVL models of the Porsche Taycan, the Toyota Mirai II, the Toyota Yaris Hybrid, the Hyundai IONIQ 5, the Tesla Models 3 and Y, and many more vehicles. The database is being updated continuously and specific models can be created on request at any time.

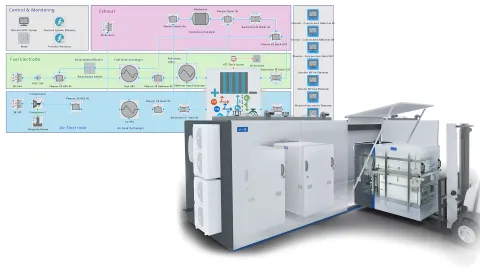

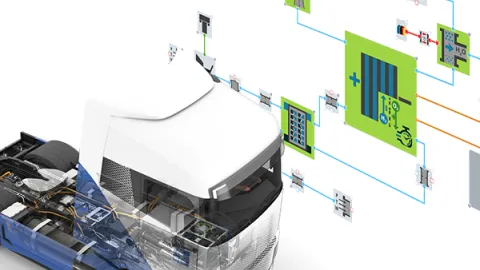

Electrochemical Model for PEM and SO Fuel Cell

The software's proven real-time capability makes it ideal for developing operating strategies on virtual testbeds. This enables the analysis of operating conditions such as high-altitude operation or freeze-start strategies, which otherwise require complex tests on climatic testbeds. In addition, cell and stack geometries can be calculated at high resolution in 3-D with high performance.

The real-time modeling of thermodynamic systems in CRUISE M is ideally suited for the development and optimization of Balance of Plant (BoP) components for fuel cell media supply. For low-temperature proton exchange membrane (PEM) systems, tailored models for water balance and thermoregulation cycles are used. System models of solid oxide (SO) fuel cells include a number of catalysts for conditioning and post-conditioning of the media streams.

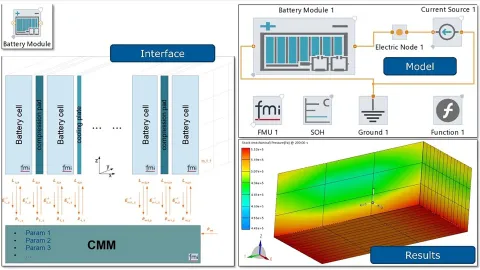

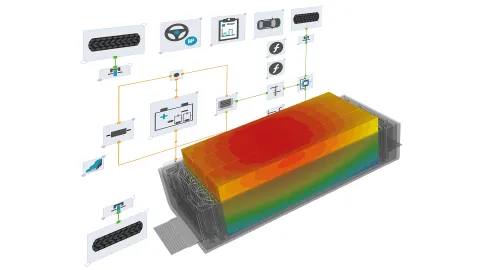

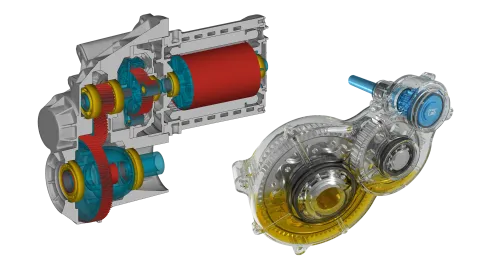

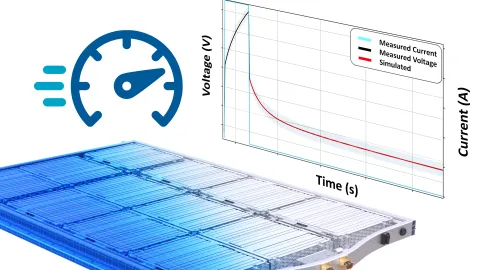

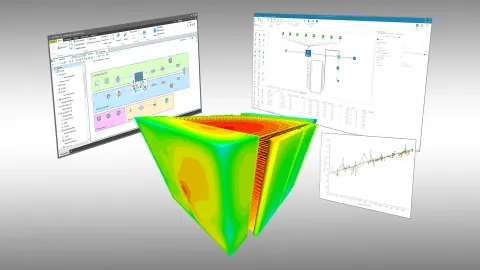

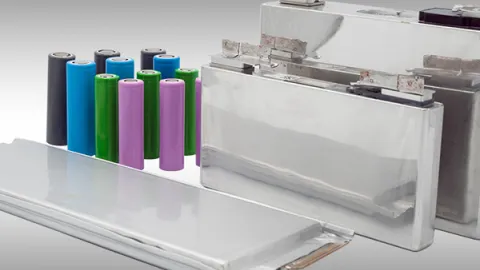

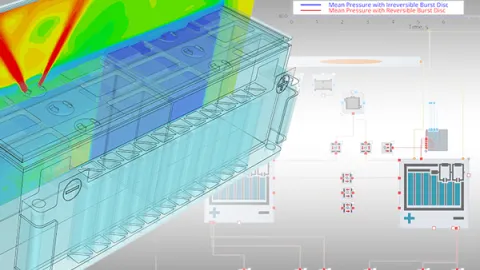

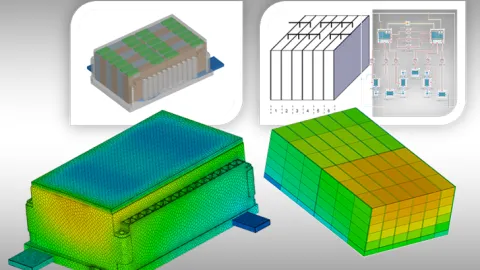

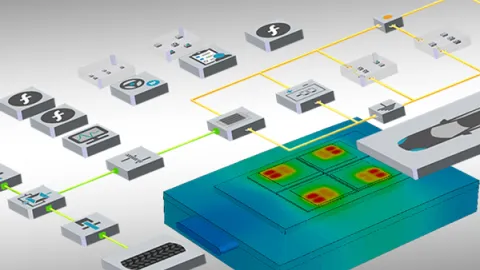

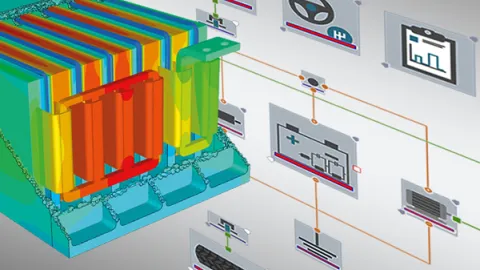

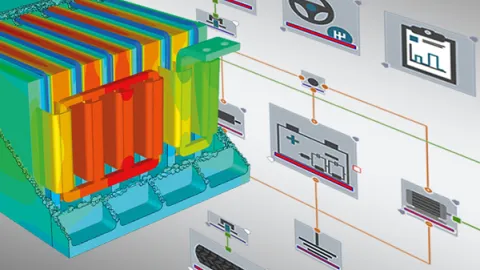

Multiscale and Multidomain Model for Battery Modules

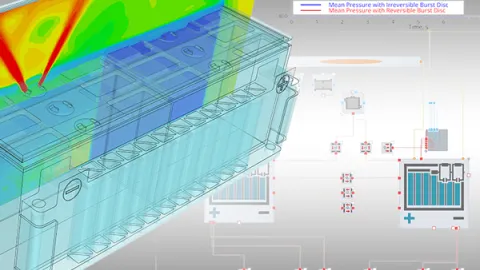

The electrochemical behavior of battery cells is strongly influenced by temperature. Temperature in turn depends on both electrochemistry and thermal management of the battery module. CRUISE M provides you with a customized component that allows you to model these causal chains across multiple scales and domains effortlessly.

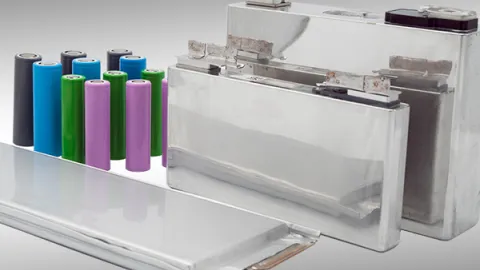

The module components for pouch, prismatic and cylindrical battery cells capture the electrical, thermal and mechanical coupling of the individual battery cells. This enables the analysis of thermal management concepts and fast charging strategies. You can choose between cell models from the CRUISE M library or your own models.

If you want to investigate new battery types virtually, CRUISE M offers extensive configuration options from electrode materials down to intercalation and aging chemistry. Importantly, your IP remains protected even when sharing models with partners.

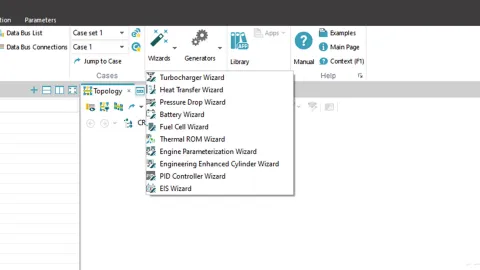

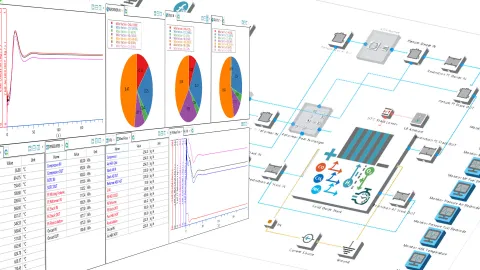

Parameterization Wizards

To relieve you from the manual setting of parameters, CRUISE M has a number of wizards.

There are wizards available for parameterizing batteries, fuel cells, turbochargers, cylinders, pressure losses and much more. The wizards guide you through all input steps and you get a parameterized component quickly and easily.

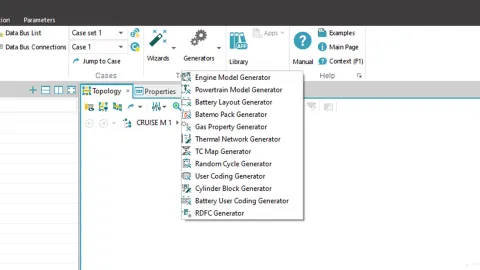

Model Generators

Do you have only rough performance data of your system? CRUISE M creates a detailed, complete model from it, too.

Model generators are available for battery packs, fuel cell stacks, combustion engines, vehicle drives and much more. The model input parameters of all components are set automatically.

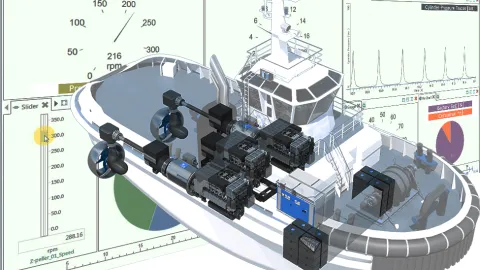

Modelling and Simulation of a Fully Electric Hybrid Propulsion System for Passenger Ships Using AVL CRUISE™ M Software

The maritime industry's pursuit of sustainability drives the exploration of alternative fuels, with hydrogen emerging as a promising solution. This paper describes a comprehensive study on a fully electric hybrid propulsion system for passenger ships, utilizing hydrogen as the primary power source.

AVL White Paper - Efficient Battery Thermal Management in BEVs

In this paper we present a numerical approach using AVL CRUISE™ M to design a snake shaped cooling channel for cylindrical cells.

AVL White Paper – Virtual Integration of xEV HVAC Systems in the Vehicle Thermal Network

In order to increase the driving range of Electric Vehicles it is essential to address the issues of thermal management and HVAC. The easiest and most efficient way to do this is by using system simulation complementary to real-life testing and experimentation. Download this White Paper to discover how many tasks can be frontloaded to a much earlier stage in the vehicle development process with the help of simulation.

AVL White Paper – VTMS Layouting of xEVs using System Simulation

Components of electrified powertrains are very sensitive regarding their operating temperature. Therefore, their proper temperature prediction during transient vehicle operation is essential. Download this whitepaper to see how our simulation solution combines thermal with mechanical and electrical systems in a consistent environment.

AVL White Paper – Model-Based Control Function Development for Gas Engines

Model-based development enables frontloading of control-system development. Download this White Paper to learn more about our approach on model-based control function development for gas engines.

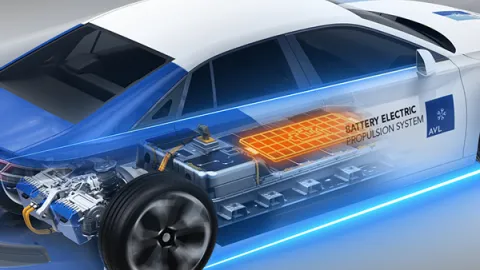

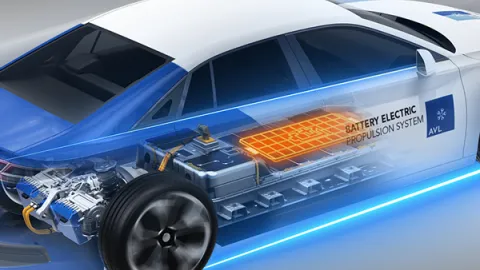

AVL White Paper – The Role of System Simulation for Battery Electric Vehicle Development

OEMs that succeed in bringing electric vehicles to market fast are in a strong position to dominate the industry. System simulation is the key to accelerating their development. Download our white paper and find out how it supports the analysis of the overall powertrain along the whole process and today.

AVL White Paper – Virtual Fuel Cell Performance and Lifetime Optimization - From Component to Vehicle Level

Download our white paper to find out how AVL eSUITE™ helps OEMs and suppliers get the best performance and longest lifespan from this clean power source.

AVL Customer Case Study – Simulation of Fuel Cell Systems at ZBT

In the case of fuel cell electric vehicles (FCEVs) the configuration of the fuel cell system and the traction battery, interaction of the two components in terms of resulting performance, efficiency, and range are particularly crucial.

AVL Customer Case Study - System Simulation in BEV Development at EDAG

For battery electric vehicles (BEV), the high-voltage storage unit is the crucial component in terms of performance, efficiency and range. To optimize these attributes extensive investigations are required. Both in the overall vehicle context and under different, sometimes extreme boundary conditions.