An e-axle, or e-drive unit, integrates the e-motor, inverter, transmission, and often the differential into a single compact system with high power density. This integration improves efficiency and performance but also poses unique challenges for e-axle performance testing, as the components can no longer be evaluated in isolation.

Modern e-axle testbeds must therefore cover service lifetime, performance, and thermal behavior standards across all electrical and mechanical subsystems. Cross-functional testing under vehicle-like conditions is essential to ensure reliable performance, thermal endurance, and overall system integrity. To reduce development time and cost, e-axle test systems should also offer easy installation with minimal facility impact and the flexibility to adapt to future requirements.

Minimized TCO

Pre-engineered solution to be productive in testing as soon as possible.

Increased Efficiency

Accelerate your productivity with a seamless integration of all tools including the automation system.

Rising Complexity

Need for a comprehensive test system with a seamlessly integrated automation system.

Standards Compliance

Rigorous testing standards for all electrical and mechanical subsystems must be fulfilled.

Performance Testing for Light-Duty

The AVL E-Axle TS™ Performance Light-Duty is a customizable solution to develop and validate your light-duty e-axle, supporting both single and twin motor configurations. It offers efficient testing for service lifetime and thermal endurance, as well as analyzing electrical, mechanical and thermal characteristics.

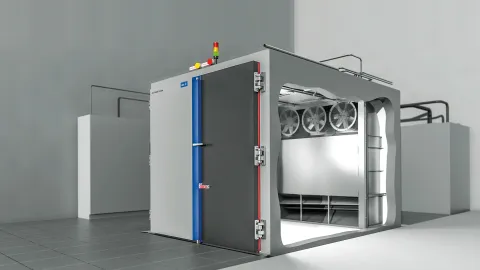

The System consists of two dynamometers as load system which are installed on one common frame – no dedicated testbed pit required. A flexible UUT support frame allows quick rigging, reducing testbed downtime, while climatic chambers and conditioning systems enable testing under various conditions. With an integrated DC source in the inverter to reduce grid power needs, the system is pre-tested and ready for containerized installation, enabling rapid testing setup.

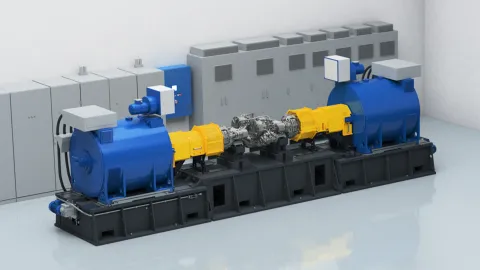

Performance Testing for Heavy-Duty

The AVL E-Axle TS™ Performance Heavy-Duty is designed for specialized testing under vehicle-like conditions. It features a reliable load system with two compact torque motors, specifically developed to fulfill the performance requirements of commercial vehicles. These motors cover the typical torque, speed, and power range without the need for maintenance-intensive reduction gearboxes.

Thanks to its compact frame design, the system can be installed directly on industrial floors without requiring a specific test system foundation. A modu-lar rigging system simplifies UUT handling, while optional climatic chambers support thermal conditioning for in-depth testing. The combi-nation of torque motor technology, scalability, and ease of use makes this system a powerful tool for evaluating performance, durability, and thermal behavior.

Ready for Testing

Short delivery time of only

8 months after order (EXW).

Testing Efficiency

Optimized UUT rigging increases testing efficiency and reduces testbed down time.

Versatile Solution

Designed for common industrial floors without requiring a specific test system foundation.

Small Installation Size

Compact testbed design:

5.000 x 1.900 mm (LD)

8,000 x 1,700 mm (HD)

Automation Software

Our advanced automation software, AVL PUMA 2™ allows systematic e-axle testing for a wide range of applications. It enables precise measurement and closed-loop control of key parameters such as speed and torque.

Energy Efficiency

Modern converter technology allows the integration of a galvanic isolated DC source to supply the power electronics of the e-axle into one drive cabinet. This reduces footprint and grid connection power.

Umwelttests

Unsere Klimakammern und Konditionierungssysteme ermöglichen Tests unter verschiedenen klimatischen Bedingungen. Dies ist zwingend erforderlich, um die Teststandards wie HTOE und PTCE bei der Entwicklung von E-Antrieben zu erfüllen.

From customer project insights, we developed a test system unlocking the full potential of e-axle testing. This empowers our customers to efficiently execute their testing strategies, and successfully bring their e-axle developments to life.”

– Christian Wooning, System Line Manager, AVL Deutschland GmbH

AVL E-Mobility Testing Solutions – Brochure

From battery to full vehicle, from products, to test systems to whole test facilites – learn how we can support your testing needs.

AVL E-Axle TS™ Performance Light-Duty – Solution Sheet

The test system for integrated perfection.

AVL E-Axle TS™ Performance Heavy-Duty – Solution Sheet

A smarter way of testing e-axles.

Tech Center Module – AVL E-Axle TS™ – Solution Sheet

The fast lane to ramp up e-axle testing.