Innovative technologies suitable for series products are essential for the development of electric vehicles with more range and power, and with faster charging times. This affects component and system levels, as well as development and production. As a central element that allows the electric propulsion unit to function, power electronics must meet stringent requirements: above all, a high level of efficiency, the best possible power density and a long service life. Guaranteeing this in a cost-effective manner requires expertise and a high degree of flexibility and modularity. All of this is necessary at system and subcomponent level, in the development process itself, as well as during testing and validation.

Size, Weight and Power Densit

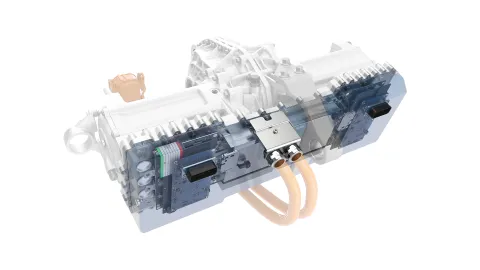

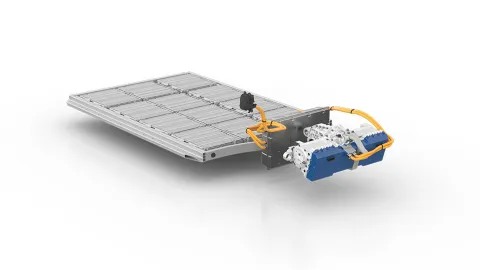

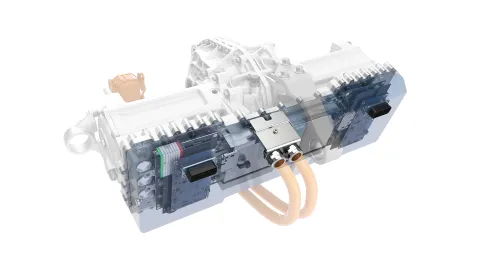

As power electronics components become smaller and more compact, the vehicle is also lighter. This gives engineers increased freedom when integrating these components into subsystems, such as the e-axle, as well as into the complete vehicle. This is especially important as the market is showing a trend towards deeper integration of multiple functions in combined units (e.g. DC/DC converter and OBC).

Performance and Efficiency

Increased efficiency of conversion from DC to AC allows an increased range. This can also reduce battery costs.

Lower System Cost

The selection of components and the system approach are key to keeping overall system costs low.

The development of power electronics and software is significantly influenced by a variety of factors. There are external requirements, such as ASIL (Automotive Safety Integrity Level) for functional safety (ISO 26262) or Cyber Security (e.g. ISO 21434) and Automotive SPICE, while customers also have specific development requirements. Our development processes always bear these requirements in mind.

That is why we have our own team focusing on processes and quality. We are familiar with the regulations, especially in the software development area, and we have A-SPICE Level 3 certification. Thanks to our expertise with electronics and software, as well as our safety and security knowledge, we can provide you with support in all relevant areas of power electronics development.

In addition to in-depth system and component expertise, we also possess state-of-the-art development and validation methods as well as testing facilities. This allows us to offer you tailored e-mobility solutions, including inverters or DC/DC converters, which can be used for series production.

You also benefit from our role as a technology pioneer. We have been developing 800 V systems for mobility application for over ten years. We also focused on new semiconductors, such as silicon carbide (SiC), early on. This made us the trailblazers for the technical innovation that now enjoys an established market position.

Single Source of Development

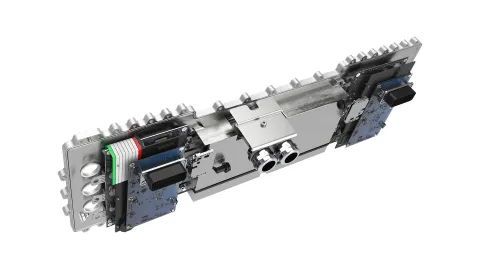

We develop all subcomponents for the inverter and DC/DC converter in-house for you, as well as the corresponding software. We work very closely with established suppliers to select semiconductor switches and modules, and are also part of collaborative development projects.

Electromagnetic Compatibility (EMC)

We use innovative EMC simulation to optimize power electronics. We have also developed technologies, such as the active hybrid filter, for more cost-effective electromagnetic noise reduction that also requires less space than passive filters only.

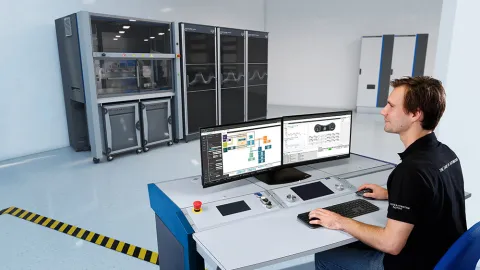

In-House Testing Facilities

Thanks to development of our in-house testing infrastructure, we can quickly test and validate all systems and components for you, in a cost-efficient manner.

Safety and Security

We ensure functional safety, component reliability, and protection from cyberattacks.

Research and Development

We drive in-depth research regarding the application and peculiarities of semiconductor materials. The expertise obtained through this allows us to develop optimal control strategies and electronic hardware architecture for increased power density, lower costs, and optimal efficiency.

Platform Solutions

We have established multiple inverter and DC/DC platforms that are operating successfully as prototypes. Based on these prototypes, we can drive customer-specific developments more quickly and more cost-effectively

Flexibility

Since we are not bound to existing production, we can work fully flexibly in terms of development services and technical solutions.

Power Electronics from Prototypes to SOP

Many years of experience in electronics and software development, and comprehensive experience of standards and processes in the automotive industry – these are optimal conditions for developing products that are compact, cost-effective, and highly efficient. This allows us to significantly increase efficiency and speed of development, while simultaneously meeting safety and security requirements. We are able to produce prototypes and small series in-house. For larger quantities, we have established processes and cooperation models with production partners. We also provide support if you intend to take on series production yourself.

EMC Simulation and Optimization

Our own simulation methodology allows us to identify and solve problems at a very early stage of development – without expensive hardware and costly tests. This reduces the risk of complex iterations in development.

Software

With our specially developed software, you can improve the performance and efficiency of your power electronics. We support the development of basis and application software.

Integration

We develop everything – from electronics and e-motors to e-axles – and we are experts on how best to incorporate the combined system into the vehicle. This provides us with unique integration knowledge that we can apply to support you.

Our work requires us to react flexibly to a range of requirements for our international customers. We are driven by the desire to find the perfect solution for everyone.

– Anton Angermeier, Executive Managing Director, AVL Software and Functions GmbH

Related Topics

We are constantly working on new solutions. The following might be interesting for you: