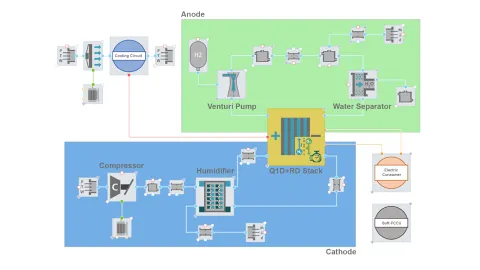

BoP components used in a fuel cell system have to meet specific requirements for performance, durability, material compatibility, noise emission and many more. As fuel cell technologies are evolving, components supplier are facing changing requirements. Without a complete fuel cell system the isolated component testing is a complex task to fulfill. At AVL, due to our in-house fuel cell development activities, we have a deep component know-how and system understanding, which we are translating into state-of-the-art testing solutions. With a system focus in mind and an understanding of changing boundary conditions, we design modular test solutions to cover every aspect of BoP testing needs.

Test procedures

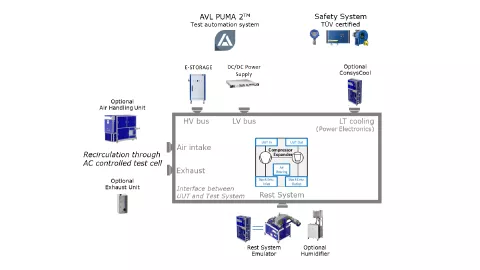

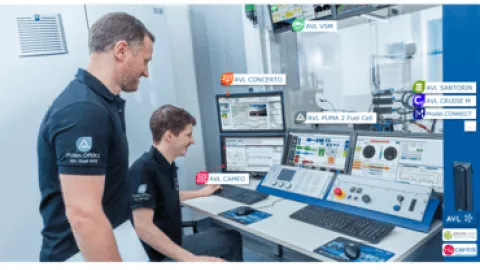

AVL PUMA 2TM for component testing is the operating system for every testbed and builds the data backbone between different testing environments. Test procedures can easily be exchanged, and data can be collected in a consistent format.

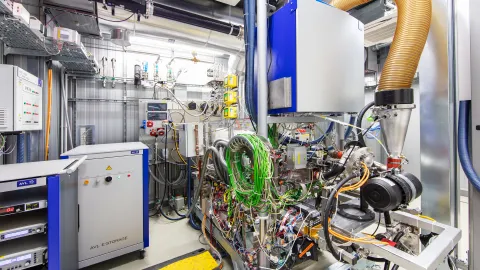

Emulation of real load conditions

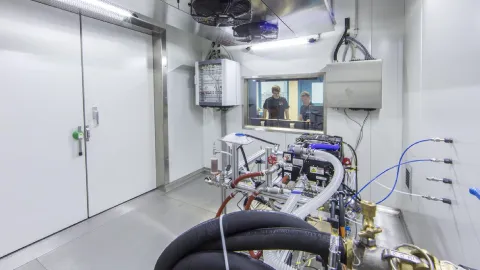

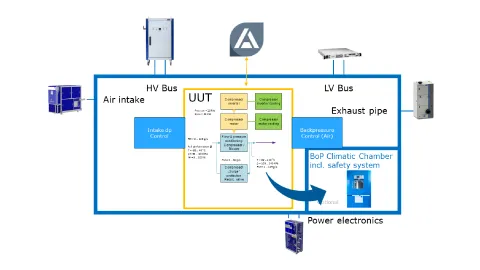

AVL testing solutions are focusing on a system engineering approach. True load conditions are emulated with innovative equipment and testbed layouts to isolate the unit under test from irrelevant disturbances and provide reproducible results.

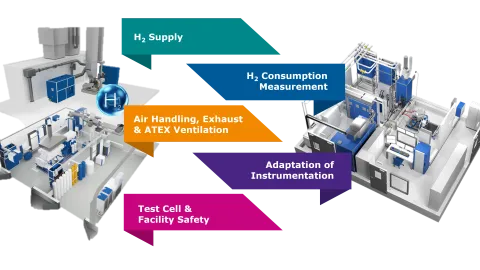

Testbed safety

AVL is providing a TÜV certified safety system with every testing solution and is able to consult on hydrogen safety layouts.

Front loading

AVL’s integrated and open development platform enables an easy exchange of parameters between test environments and allow for a simulation centric development approach shortening development times and increasing the development effectiveness.

With more than two decades of fuel cell experience AVL is the right innovation partner to reach your development goals.

360° fuel cell system expertise

AVL is providing a holistic approach to fuel cell development from engineering services to simulation methodology and tools to innovative testing solutions for every aspect in the development phase and beyond to production.

Upgradable

With the modular test bed design you will invest into a future proof testing environment which grows with your testing demands.

Simulation-centric

At AVL we are innovating how new technologies are developed. Our complete toolchain allows to connect all testing environments seamlessly and provide a consistent parameter and data flow which supports a simulation-centric systems engineering approach.

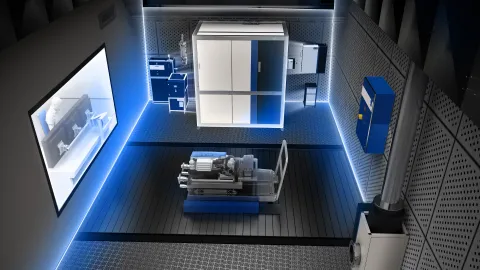

Modular approach

AVL BoP testing solutions are modular and tailored to customer-specific R&D requirements targeting future applications in the automotive, aviation and marine industries. This modular approach delivers high flexibility to cover every aspect of the BoP development process and a high degree of upgradability for seamless adaptation to evolving R&D demands.

Solution Consultancy

With a proven track record of more than over two decades of fuel cell experience, AVL’s competence covers the entire BoP development process, from target definition through the engineering phase to turnkey solutions for a wide range of R&D requirements. Guidance along the entire process by AVL fuel cell experts leads to high-end, customer-specific BoP testbed solutions.

AVL PUMA 2™ Fuel Cell

AVL’s real-time automation system is the perfect match for the entire BoP development program. Its flexibility and compatibility allows seamless exchange of use cases and test procedures across all testing environments and offers simple interface modification for any given use case. The remarkable interplay with AVL’s proven toolchain and the given data consistency across all testing environments makes it the perfect tool to optimize and accelerate the BoP development process.

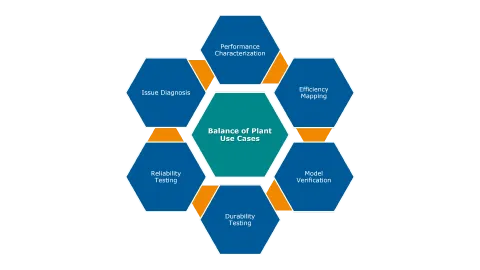

Use Cases

AVL BoP testing solutions are optimized for a wide variety of use cases, e.g. performance characterization, efficiency mapping, model verification and durability testing. This extensive portfolio, combined with AVL’s profound expertise in component and system testing, makes AVL an ideal innovation partner within the framework of BoP development.