Mobility is undergoing its biggest changes since the invention of the automobile. Makers of today’s electrified powertrains are looking to integrate drive inverters as key components of electrical powertrain systems.

Our complete integrated solution covers all inverter testing requirements that arise from automation, limit monitoring and measurement. Furthermore, easy parameterization and online operation of the AVL E-Motor Emulator™(E-ME) leads to most efficient inverter testbed operation.

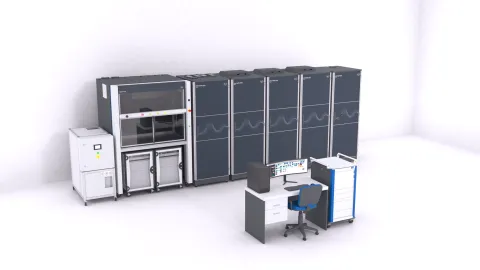

Real-time data collection and fast access to all measurement devices and test cell facilities guarantee reliable and consistent measurement results. But the key advantages of PUMA 2 Inverter lie in its ease of use.

Graphical parameterization simplifies the definition of test cycles, and the centralized management of users, projects and quantities puts everything you need in one place. The system can be integrated with more than a hundred different measurement devices, including tools from third party suppliers. Last but not least, the built-in Device Driver Studio offers almost limitless compatibility with other systems.

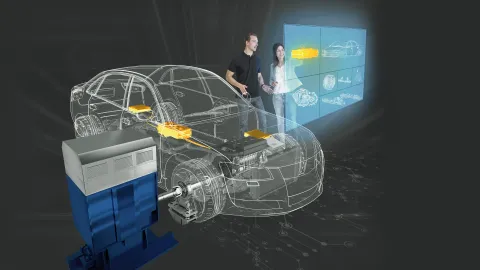

Based on our AVL PUMA 2™ system – the global industry standard for testbed automation – PUMA 2 Inverter allows you to prepare and validate your testing tasks right from the office. This saves valuable testbed time, and maximizes ROI.

Fully Automatic

Maximize the usage of testbeds by defining and executing a sequence of predefined tests including fully automated test runs

Maximize Productivity

Usability, compatibility and simplicity are at its very heart, helping to reduce your effort, cut downtime and maximize productivity.

Highly Flexible

Possibility to share data across different testbed types and configurations

Our E-motor emulator (E-ME) is a game changer to the inverter testing methodology and PUMA has helped us making a full inverter test system out of it.

– Horst Hammerer, Director Electric System Testing, AVL List GmbH

AVL PUMA 2™ Inverter Solution Sheet

DownloadAbout AVL

With more than 11,000 employees, AVL is the world’s largest independent company for development, simulation and testing in the automotive industry, and in other sectors. Drawing on its pioneering spirit, the company provides concepts, solutions and methodologies to shape future mobility trends. AVL creates innovative and affordable technologies to effectively reduce CO2 by applying a multi-energy carrier strategy for all applications – from hybrid to battery electric and fuel cell technologies. The company supports customers throughout the entire development process from the ideation phase to serial production. To accelerate the vision of smart and connected mobility AVL has established competencies in the fields of ADAS, autonomous driving and digitalization.

AVL’s passion is innovation. Together with an international network of experts that extends over 26 countries and with 45 Tech- and Engineering Centers worldwide, AVL drives sustainable mobility trends for a greener future. In 2020, the company generated a turnover of 1.7 billion Euros, of which 12% are invested in R&D activities.

For more information: www.avl.com