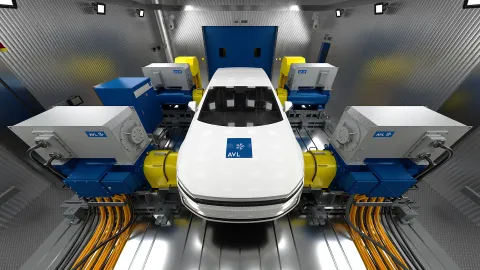

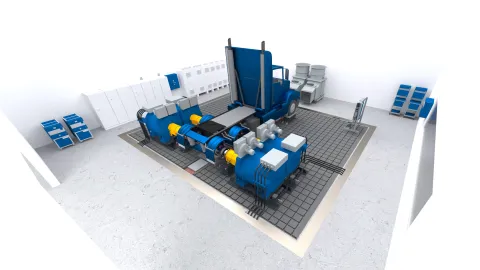

The AVL Vehicle Powertrain Test System enables full vehicle testing under various environmental conditions. Wheel hub dynamometers apply realistic, road-like loads based on a vehicle dynamics model, allowing highly accurate and repeatable test scenarios – even during dynamic maneuvers.

Direct torque measurement at each hub provides deep insights into energy flow and losses, enabling a detailed analysis of the vehicle’s overall energy consumption.

To ensure maximum efficiency, the system integrates the AVL PUMA 2™ automation platform and AVL EMCON 6™ inverter control. Together, they deliver precise, synchronized data acquisition across all subsystems – supporting a wide range of test cases with high accuracy and reliability.

Standards Compliance

Rigorous testing standards for energy consumption and driving range.

Rising

Complexity

Sophisticated testing procedures and equipment are needed.

Interconnected Systems

Combined optimization of mechanical and electrical subsystems is mandatory to achieve vehicle target.

Productivity and Efficiency

Testing processes must be productive and efficient to meet development timelines.

Ready for the Future

All set for broader range of environmental and driving conditions.

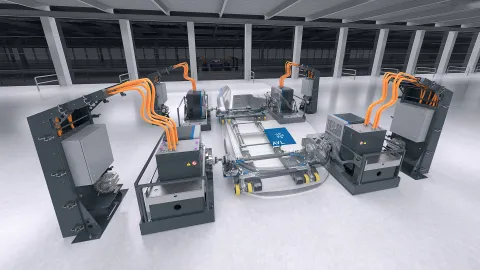

Battery electric vehicles introduce new levels of complexity to vehicle testing – increasing both system requirements and operational costs. Our Vehicle Powertrain Test Systems are specifically designed to evaluate energy flows in line with current regulations and future development needs.

Our solutions are defined by key features that ensure flexibility, precision, and efficiency:

- Wide power range: Suitable for passenger cars, light-, medium-, and heavy-duty vehicles

- Flexible layout: No baseplate required, adaptable to various testing environments

- Adjustable wheelbase: Configurable for different vehicle types and sizes

- Fast and easy rigging: Enabled by the AVL X-Rig™ for quick testbed setup

- Synchronized energy measurement: Accurate analysis of power and energy flow

- Climatic testing capabilities: Temperature range from -40 °C to +60 °C

- Solar emulation: For realistic thermal and charging scenarios under sun exposure

Energy Consumption and Driving Range Optimization

Real world driving under climatic reproducible lab conditions.

High Accuracy

Precise synchronous measurement of speed, torque, temperature, pressure, flow, voltage and current.

Efficient Rigging

Easy and fast rigging and replacement of different vehicles for minimal downtime and highest testing efficiency.

Vehicle powertrain testing is essential for evaluating the complete electric vehicle as an integrated system. It allows us to analyze energy flows across all components, validate thermal strategies, and optimize efficiency and driving range – all under controlled, repeatable, and road-realistic conditions.”

– Klaus Pfeiffer, Systemline Manager Light-Duty, AVL Germany

AVL Vehicle Powertrain TS™ Light-Duty – Solution Sheet

More efficient than road testing.

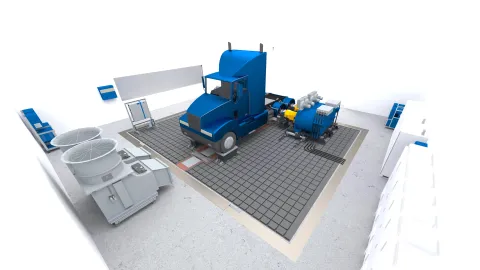

AVL Vehicle Powertrain TS™ Heavy-Duty – Solution Sheet

One test system for all stages of powertrain development.

AVL Vehicle Powertrain TS™ Energy Flow – Solution Sheet

Whether hot or cold, improve your driving range.