OEMs and suppliers are now developing components for innovative propulsion systems. Unlike the previous focus on ICE, the shift to fully electrified drivetrains introduces new challenges.

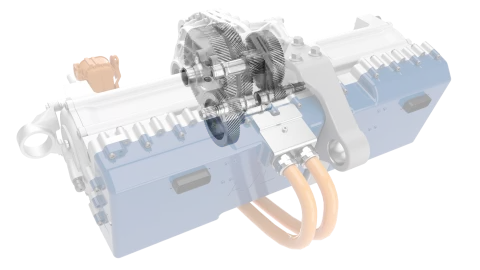

Our drive units must adapt to these changes by supporting e-drives, which require smaller, high-power-density solutions capable of higher speeds and greater flexibility. The design of e-motors also introduces a wider range of variants compared to ICEs, demanding more versatility from our testing systems.

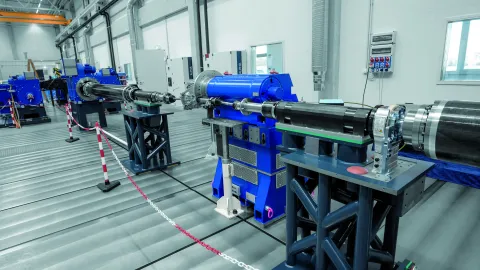

Our transmission test systems are engineered to validate a wide range of transmissions, addressing varying types, speeds, and power classes. The main challenge lies in integrating an ICE or e-motor within a compact, close axle arrangement. The AVL drive unit is designed to meet the necessary speed and torque requirements while ensuring compatibility with the available installation space. Our solutions are capable of handling the variability of e-axles in both co-axial and offset configurations, along with the intelligent mechanical connection of e-motors to transmissions.

The optimization of the design and validation process is a key benefit, as our systems allow for early-phase transmission testing, even without a fully developed propulsion unit. This reduces the likelihood of design changes in later development stages. In addition, AVL PUMA 2™ automation software adds significant value to the testing process by synchronizing data from all connected devices. This results in precise measurement and control, enabling faster transmission system development through various test types, such as transient, time-lapse, and road load simulation tests.

Nothing is more constant than change. As transmission architectures evolve, so must our testing solutions. With AVL’s expertise and reliable systems, our customers can confidently validate performance and focus on what matters most – innovation and development.”

– Dr. Klaus Pfeiffer, System Line Manager, AVL Deutschland GmbH

Our transmission testing solutions combine advanced, proven products, including drive systems and load systems for various speed and power classes, along with automation software supporting a wide range of applications. With deep application expertise and seamless system integration, we enhance the efficiency of our customers' processes. Whether for durability, performance, or efficiency testing, our transmission test systems provides the ideal solution for your specific needs

-

Evaluation of strain limits for transmission cases and rotating parts

-

Assessment of gear teeth and bearing lifetimes

-

Determination of clutch pack and brake lifetimes

-

Optimization of component dimensioning

-

Analysis of driving performance and strategies

-

Option to upgrade to maneuver-based testing

AVL Test System Automation – Brochure

Tailored Software Solutions for Future-Proof Test Environments.

We offer transmission test systems for various test applications.

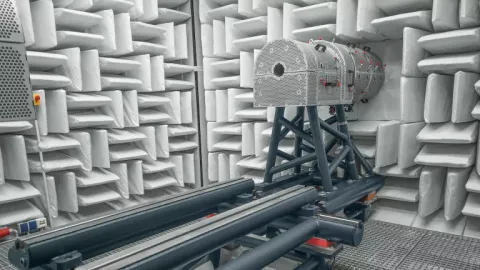

At AVL, we develop e-axle solutions that can be easily installed without impacting the productivity of your engineering facility.

With increasingly strict emissions restrictions across the world, and demand for affordable vehicles with low fuel consumption that do not sacrifice comfort, the automotive industry is facing enormous challenges.

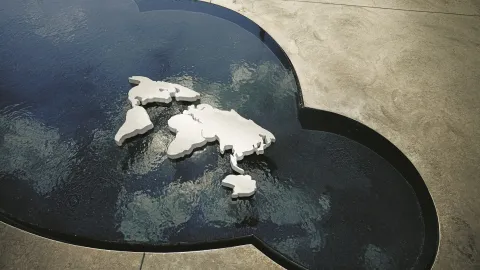

The AVL Customer Services organization consists of more than 700 service- and application engineers worldwide, operating from more than 50 locations. Our global footprint is your local benefit.

AVL PUMA 2™ is the global industry standard for testbed automation. It is suitable for electrified testbed types as well as for conventional test environments.

Transform your e-mobility analysis with AVL CONCERTO 6™, featuring fast data access, AI-driven technologies, advanced visualizations and calculations, and auto-generated reports for superior performance and precise insights.

The market-leading testbed monitoring and control system for a variety of propulsion systems

Battery tester and emulator for research and development, testing, and validation purposes.

AVL’s comprehensive worldwide network of experts allows best customer vicinity, ensuring consistent and connecting testing fields globally. Wherever your R&D challenges take you, we are always close at hand, ready to provide the service you need.

> 70

years of experience

> 5,000

employees worldwide for testing solutions

> 30

countries covered by the global network

> 7,000

testbeds installed worldwide

> 80

turnkey projects