With over 25 years of expertise in developing advanced conditioning systems and technologies, we have equipped high-end engine test cells worldwide. This extensive experience forms the perfect foundation for understanding the growing complexity of cooling circuits in electrified propulsion systems for automotive applications. It also enables us to deeply comprehend the specific thermal management needs of our customers.

A VTMS plays a crucial role in enhancing the energy efficiency and durability of key components within the propulsion system, including the battery and inverter. To achieve optimal performance, highly efficient systems require in-depth calibration and testing at the vehicle level, which significantly impacts development costs and timelines.

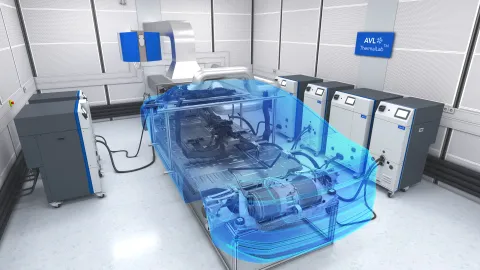

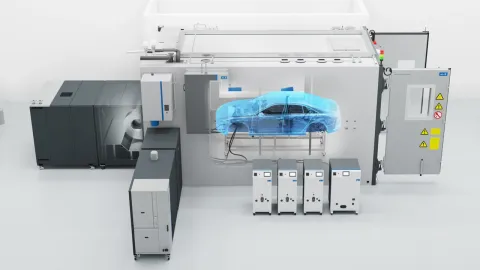

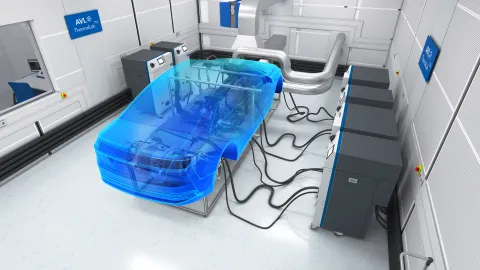

AVL ThermalLab™

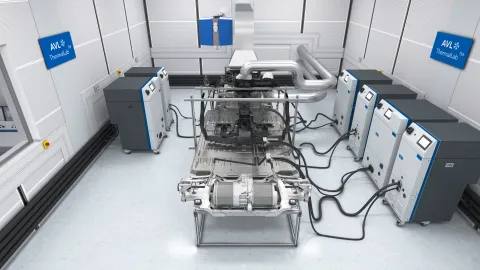

The AVL ThermalLab™ assists in optimizing the entire VTMS process by simulating coolant circuits and embedding the complete system in an emulated vehicle. Our ThermalLab allows for comprehensive system testing in a laboratory setting, replicating realistic driving and environmental conditions, independent of vehicle prototypes and weather. Additionally, it supports thermal component optimization, even without access to the entire VTMS. The UUT can be integrated into an emulated vehicle, while the remaining thermal system and environment are simulated using a hardware-in-the-loop (HiL) method.

Media Conditioning Systems

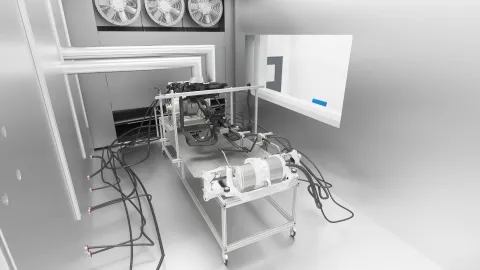

The wide range of drivetrain concepts, from conventional to hybrid to fuel cell electric and battery electric, has increased the demand for testing that closely resembles real-world driving conditions. The thermal condition and environment of UUT have a significant impact on the real-driving results. Therefore, the simulation must be as precise as possible. To achieve this, high-performing media conditioning systems are essential. They must allow for adjustability to real in-vehicle conditions and guarantee high stability in both constant and dynamic operation. Additionally, they must be able to simulate extreme environmental conditions.

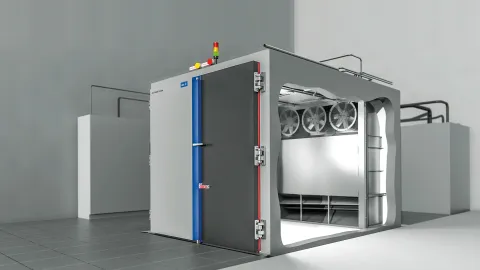

Batteries, fuel cells, e-motors, and e-axle solutions must operate safely and reliably in any environment. This can entail exposure to extreme temperatures and humidity, which are challenging to replicate on the test track or in real-world road tests. To address this, we developed the our climatic chambers. These innovative solutions safely and reliably simulate a wide range of harsh environmental conditions, providing high flexibility while minimizing system downtime. Their distinctive application-based design with pre-defined interfaces ensures seamless integration into existing testbeds.

We provide products, solutions, and systems for thermal and environmental conditioning to enable our customers to develop their products with the highest level of efficiency.”

– Stefan Nemec, Global Business Segment Manager, AVL List GmbH

For several years, we have been at the forefront of developing advanced media conditioning systems and technologies used in the world’s leading engine test cells. This experience gives us unparalleled insight into the evolving intricacies of cooling circuits within electrified propulsion systems for automotive applications.

You can benefit from our expertise and experience as we adeptly navigate the heightened pressures of the development phase. We prioritize customer satisfaction by meticulously managing project timelines and budgets. Our rigorous pre-validation of design and functionality prior to vehicle-level testing ensures seamless integration and optimal performance.

AVL E-Mobility Testing Solutions – Brochure

From battery to full vehicle, from products, to test systems to whole test facilites – learn how we can support your testing needs.

AVL Thermal Testing Solutions – Brochure

Keep Cool, Drive Further.

AVL Climatic Chamber Portfolio – Brochure

Ensuring E-Mobility Reliability Through Extreme Environmental Testing.

AVL Conditioning Systems – Brochure

Simulate real and extreme conditions with best reproducibility.

Optimizing Thermal Management in EVs – Whitepaper

Up to one third of EV energy is consumed by thermal systems.

AVL’s automation platform PUMA 2™ represents the brains behind many different testbed applications. Our leading automation system is easily extendable to suit modern testing methods and ensures consistent and transparent testbed configuration.

AVL PUMA 2™ Thermal Lab Testing features an outstanding intuitive user interface displaying all important values immediately. Our testing processes are efficient and accurate, utilizing simulation software and automated test runs for consistent results. The incorporation of machine learning, real-time monitoring and the openness of our automation platform facilitate rapid failure detection, cost reductions, and shorter time-to-market.

AVL ThermalLab™ tests the entire VTMS, including all coolant circuits and the refrigerant cycle, under dynamic conditions using model-based testing. The UUT is the complete VTMS embedded in an emulated vehicle while the environment is fully simulated. The entire system can be tested in the lab under realistic driving and ambient conditions.

Thermal conditions and environment of Units Under Test have strong impacts on real results in driving. For this reason, the thermal simulation must be as exact as possible – which can be achieved via deployment of high performing media conditioning systems.

Battery packs, modules and cells, fuel cells, e-motor and e-axle solutions must operate safely and reliably in any environment. This can include extreme temperatures and humidity, which cannot be reproduced on the test track or in real test scenarios on the road. This is why we developed the modular AVL Climate Chamber.

For battery (module/pack) testing, we offer complete test systems, stand-alone equipment, or even entire turnkey test labs.

At AVL, we develop e-axle solutions that can be easily installed without impacting the productivity of your engineering facility.

AVL has a wide portfolio consisting of dedicated e-motor test systems, software, tools, and processes to test and validate these modern e-drive systems in shortest time and with highest quality standards.

The AVL Customer Services organization consists of more than 700 service- and application engineers worldwide, operating from more than 50 locations. Our global footprint is your local benefit.

Intelligent automation, quick and easy

25 years of experience in the development of conditioning systems for automotive test systems form the basis for our in-depth understanding of cooling circuits in different electrified propulsion systems. It is also a good base for understanding our customers’ needs regarding thermal management system development.