Vehicle Interior Air Quality Testing

A Shift in Perspective: From Exhaust Emissions to Interior Air Quality

Historically, the focus in vehicle emissions discussions has been primarily on exhaust gases produced by combustion engines. These emissions are undoubtedly a major environmental and health concern, especially in urban areas. However, another critical aspect is coming into view: the quality of air inside the vehicle cabin.

Interior air is the immediate breathing environment for passengers – making it equally important for their health and comfort. Factors such as materials, manufacturing processes, environmental conditions, and occupant behavior all influence vehicle air quality. It is therefore time to broaden the perspective and recognize Vehicle Interior Air Quality (VIAQ) as an essential component of modern automotive development.

Health Impacts & Regulatory Standards

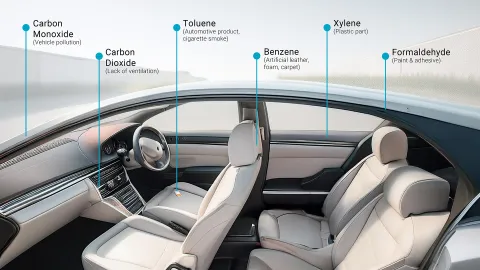

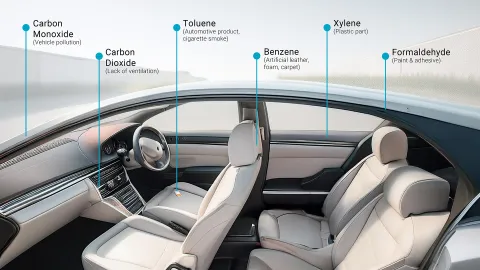

The air inside a vehicle can contain several pollutants, including volatile organic compounds (VOCs), particulate matter (PM), carbon monoxide (CO), nitrogen dioxide (NO2), and ozone (O3). Prolonged exposure to these pollutants can have detrimental effects on health, causing respiratory problems, allergic reactions, and even long-term diseases such as asthma and cardiovascular issues. Children, the elderly, and individuals with pre-existing health conditions are particularly vulnerable.

To protect public health, various regulatory bodies have established standards for indoor air quality, including vehicle interiors. These standards specify the permissible levels of different pollutants and provide guidelines for manufacturers to ensure compliance. For instance, the International Organization for Standardization (ISO) has developed ISO 12219, a series of standards specifically addressing the measurement of air quality in vehicle interiors. (WHO, 2021; ISO, 2021)

Materials and Components

One of the primary sources of pollutants in vehicle interiors is the materials used in the manufacturing process. This includes plastics, adhesives, textiles, and paints, which can emit VOCs over time. These emissions, commonly referred to as "off-gassing," can persist for months or even years after the vehicle is manufactured.

External Environment

Pollutants from the external environment can also penetrate the vehicle's interior. This includes exhaust fumes from other vehicles, industrial emissions, and dust. The air intake system of the vehicle, if not properly filtered, can introduce these external pollutants into the cabin.

Occupant Activities

The activities of the occupants, such as smoking, eating, and using personal care products, can also contribute to the air quality inside the vehicle. These activities can introduce additional pollutants and odors, further degrading the air quality.

Sampling Techniques

To assess the air quality inside a vehicle, accurate sampling techniques are essential. There are several methods for collecting air samples, including passive sampling, active sampling, and real-time monitoring.

- Passive Sampling: This method involves the use of diffusive samplers that absorb pollutants over a specified period. Passive sampling is useful for long-term monitoring and provides an average concentration of pollutants.

- Active Sampling: In active sampling, air is pumped through a sampling device, such as a filter or sorbent tube, to collect pollutants. This method allows for the collection of a larger volume of air and provides more accurate measurements.

- Real-Time Monitoring: Real-time monitoring uses sensors and analyzers to continuously measure pollutant concentrations. This method provides immediate data and can detect fluctuations in air quality. (ASTM, 2018)

Analytical Techniques

Once air samples are collected, they need to be analyzed to determine the concentration of pollutants. Several analytical techniques are used for this purpose, including gas chromatography (GC), mass spectrometry (MS), and high-performance liquid chromatography (HPLC).

- Gas Chromatography (GC): GC is a widely used technique for separating and quantifying VOCs in air samples. It involves passing the sample through a column where the compounds are separated based on their volatility and then detected by a detector.

- Mass Spectrometry (MS): MS is often used in combination with GC (GC-MS) to identify and quantify pollutants. It measures the mass-to-charge ratio of ions and provides detailed information about the chemical composition of the sample.

- High-Performance Liquid Chromatography (HPLC): HPLC is used for analyzing non-volatile and semi-volatile organic compounds. It separates compounds based on their interaction with a stationary phase and a mobile phase and detects them using various detectors. (ASTM, 2018)

KOREA MOLIT 2019-144

KOREA MOLIT 2019-144 is a regulation established by the Ministry of Land, Infrastructure, and Transport in South Korea. It sets stringent standards for the permissible levels of harmful substances in vehicle interiors, specifically targeting volatile organic compounds (VOCs) and formaldehyde. This regulation mandates regular testing and certification for new vehicles to ensure compliance, thereby safeguarding the health of vehicle occupants from potential toxic emissions. (MOLIT, 2019)

CHINA GB 27630-2017 / HJT400-2007

China's GB 27630-2017 and HJT400-2007 regulations focus on controlling and reducing harmful substances within vehicle interiors. GB 27630-2017 outlines specific limits for VOCs, aldehydes, and ketones, requiring automobile manufacturers to conduct rigorous testing during the production process. HJT400-2007, on the other hand, provides guidelines for the testing methodologies and procedures to accurately measure these substances. Together, these regulations ensure that vehicles produced and sold in China adhere to high standards of air quality, protecting consumers from exposure to hazardous chemicals. (MEE, 2007; SAC, 2011)

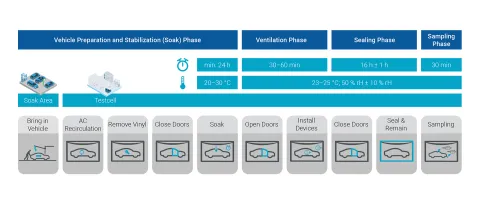

ISO 12219

ISO 12219 is an international standard that provides a comprehensive framework for measuring and evaluating air quality inside road vehicles. It encompasses various parts, each addressing different aspects of vehicle interior air testing. This includes guidelines for sampling and analysis of VOCs, aldehydes, and other pollutants. By promoting uniform testing procedures and criteria, ISO 12219 helps to harmonize air quality standards globally, facilitating cross-border trade and ensuring that vehicles meet consistent safety and health benchmarks.

These regulations highlight the global effort to enhance vehicle interior air quality, reflecting commitment to public health and safety. By adhering to these standards, manufacturers can assure consumers of the safety and cleanliness of their vehicles, contributing to a healthier driving experience worldwide. (ISO, 2021)

| China | Korea | |

| Acetaldehyde | 0.20 | 0.30 |

| Acrolein | 0.05 | 0.05 |

| Benzene | 0.05 | 0.03 |

| Ethylbenzene | 1.00 | 1.00 |

| Formaldehyde | 0.10 | 0.21 |

| Styrene | 0.26 | 0.22 |

| Toluene | 1.00 | 1.00 |

| Xylene | 1.00 | 0.87 |

Development of Low-Emission Materials

One of the key advancements in vehicle interior air quality is the development of low-emission materials. Manufacturers are increasingly using materials that emit fewer pollutants, such as low-VOC adhesives and water-based paints. These materials help reduce the overall concentration of pollutants in the vehicle interior.

Innovative Air Filtration Systems

Modern vehicles are equipped with advanced air filtration systems that can effectively remove pollutants from the air. These systems use high-efficiency particulate air (HEPA) filters, activated carbon filters, and photocatalytic oxidation (PCO) to capture and neutralize pollutants. Some vehicles also feature air ionizers that remove particles by charging them and trapping them on a collector plate.

Smart Air Quality Monitoring

The integration of smart technologies in vehicles has led to the development of real-time air quality monitoring systems. These systems use sensors to continuously measure pollutant levels and provide occupants with real-time data on air quality. Some systems can also automatically adjust the ventilation and filtration settings to maintain optimal air quality. (Lohani et al., 2022)

Addressing New Pollutants

As vehicle technology evolves, new pollutants may emerge that need to be addressed. For instance, electric vehicles (EVs) may introduce new materials and components that have different emission profiles. Researchers and manufacturers need to stay vigilant and adapt their testing methodologies to address these emerging pollutants.

Enhancing Standardization

While there are several standards for vehicle interior air testing, there is still a need for greater harmonization and standardization across different regions and regulatory bodies. This will help ensure that air quality testing is consistent and comparable, regardless of where the vehicle is manufactured or tested.

Improving Consumer Awareness

Consumers play a crucial role in maintaining vehicle interior air quality. Educating consumers about the sources of pollutants, the importance of air quality, and the steps they can take to improve it is essential. This includes regular maintenance of air filtration systems, avoiding activities that introduce pollutants, and using low-emission products.

Vehicle interior air testing is a vital aspect of ensuring the health and well-being of vehicle occupants. By understanding the sources of pollutants, implementing effective testing methodologies, and leveraging advancements in technology, we can create a safer and healthier environment inside vehicles. As the automotive industry continues to evolve, addressing the challenges and seizing the opportunities in vehicle interior air quality will be crucial in delivering a breath of fresh air to all passengers.

- ASTM International. (2018). ASTM D6245-18: Standard Guide for Using Indoor Carbon Dioxide Concentrations to Evaluate Indoor Air Quality and Ventilation. https://www.astm.org/d6245-18.html (last accessed September 2, 2025)

- International Organization for Standardization. (2021). ISO 12219-1:2021 - Interior air of road vehicles — Part 1: Whole vehicle test chamber — Specification and method for the determination of volatile organic compounds in cabin interiors. https://www.iso.org/standard/50019.html

- Lohani, D., Barthwal, A., & Acharya, D. (2022). Modeling vehicle indoor air quality using sensor data analytics. Journal of Reliable Intelligent Environments, 8, 105–115.

- Ministry of Ecology and Environment. (2007). HJ/T 400-2007: Determination of Volatile Organic Compounds and Carbonyl Compounds in Cabin of Vehicles. https://www.mee.gov.cn/ywgz/fgbz/bz/bzwb/jcffbz/200712/t20071213_114283.shtml

- Ministry of Land, Infrastructure and Transport. (2019). Regulation No. 2019-144: Management Standards for Interior Air Quality of Newly Manufactured Vehicles. https://law.go.kr/LSW/admRulLsInfoP.do?admRulSeq=2100000177221

- Standardization Administration of China. (2011). GB/T 27630-2011: Guideline for Air Quality Assessment of Passenger Cars. https://std.samr.gov.cn/gb/search/gbDetailed?id=71F772D7FE27D3A7E05397BE0A0AB82A

- U.S. Environmental Protection Agency. (2025). Volatile Organic Compounds' Impact on Indoor Air Quality. https://www.epa.gov/indoor-air-quality-iaq/volatile-organic-compounds-impact-indoor-air-quality (last accessed September 2, 2025)

- World Health Organization. (2021). WHO global air quality guidelines: Particulate matter (PM2.5 and PM10), ozone, nitrogen dioxide, sulfur dioxide and carbon monoxide. https://www.who.int/publications/i/item/9789240034228/ (last accessed September 2, 2025)