To reduce mutual interference between electrical systems, vehicle EMC standards are regularly revised, with OEM specifications becoming more stringent. Early consideration of EMC during vehicle development is crucial to identify potential issues and avoid costly redesigns and delays.

Proactively addressing EMC helps ensure compliance with global regulatory requirements, facilitating the successful market entry of new vehicle models and ensuring that all systems perform reliably within regulatory constraints.

We have expanded our EMC test systems portfolio to cover everything from components to complete vehicles, ensuring compliance with current EMC standards. Our services include pre-compliance testing on conventional testbeds and tailored solutions, from simple components to full turnkey projects. They represent our strong and long-term commitment to this highly relevant topic in the vehicle development process.

When it comes to EMC performance, our ambitious, self-imposed targets guarantee that every single EMC measurement focuses only on the point of interest, the unit under test. At the same time, we ensure that the tests are safe, precise, and as time efficient as possible.

EMC Solutions for E-Motor

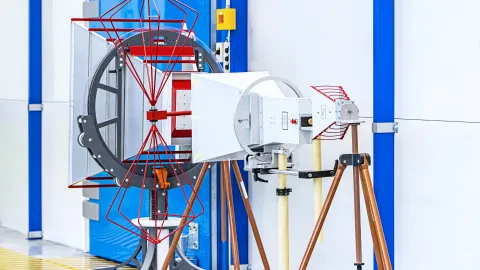

Ensuring the reliable operation of high-power electric drives near sensitive communication systems is a key challenge. We have developed solutions that meet the latest EMC standards to assess and validate EMC in real operating conditions, ensuring the optimal functionality of electronic systems. → Learn more

EMC Solutions for E-Axle

E-Axles, which integrate electric motors, power electronics, and transmissions into a single unit, require thorough EMC testing to detect and prevent electromagnetic disturbances.This ensures optimal performance and compatibility with other vehicle electronics.

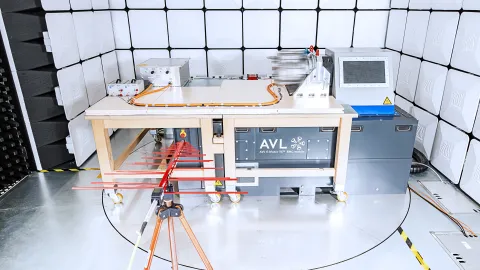

The Advanced EMC Analysis Interface is a data synchronization link between our AVL PUMA 2™ testbed automation and Rohde & Schwarz’s R&S®ELEKTRA EMC test equipment automation. Depending on the type of EMC measurement - emissions or immunity - the automations assume their individual equipment under test (EUT). Online verification and limit violation of EMC data allows to choose between maximum test speed or thoroughness. This paves the way for rapid analysis and identification of EMC problems, and automated generation of comprehensive test reports.

With an electrified powertrain, EMC behavior is influenced by operating conditions like speed, load, and braking. At AVL, we offer components and vehicle EMC testbeds for comprehensive EMS and EMI tests, adhering to strict EMC norms and a wide operating range. Our advanced software toolchain automates and accelerates complex testing tasks.”

– Alban Hemery, Dept. Manager, AVL List GmbH

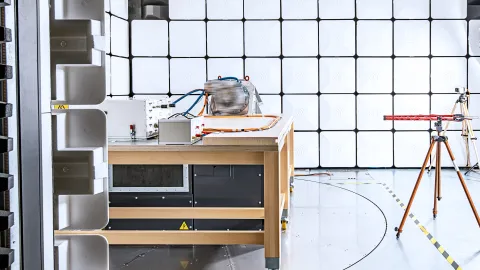

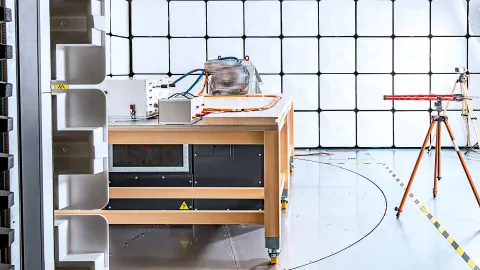

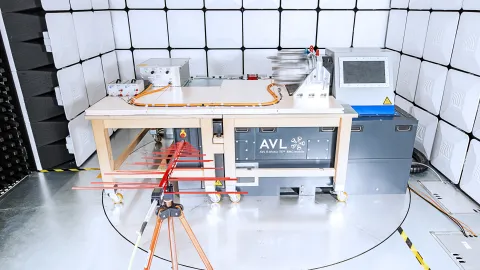

For effective EMC analysis, it is essential to rapidly and safely commission Units Under Test (UUTs), load them, and make accurate EMC measurements across the UUT's entire power range without compromise. A key feature of AVL EMC test systems is their ability to increase testbed efficiency by allowing multi-purpose use of EMC chambers and ensuring interoperability between EMC and load application hardware.

Every component of an EMC testbed contributes to the successful suppression of unwanted external influences on UUT measurements. We design our test systems by implementing comprehensive EMC concepts that ensure optimal EMC performance.

AVL E-Mobility Testing Solutions – Brochure

From battery to full vehicle, from products, to test systems to whole test facilites – learn how we can support your testing needs.

AVL EMC Test Systems – Brochure

Control your e-mission.

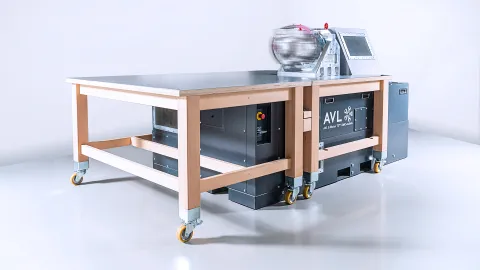

AVL E-Motor TS™ EMC-mobile – Solution Sheet

AVL E-Motor TS™ EMC-fixed – Solution Sheet

Validate the electromagnetic compatibility of your electric drive with our specialized test system.

The perfect hardware for AVL’s leading automation system

The AVL Customer Services organization consists of more than 700 service- and application engineers worldwide, operating from more than 50 locations. Our global footprint is your local benefit.

AVL's global presence and locations close to our automotive customers enable us to respond quickly to challenges in the world of EMC testing. The continuous improvement of our test systems and the clear commitment to keep up-to-date with every technological trend enable us to support our customers worldwide. Our steadily growing customer base ranges from independent test institutes and Tier X suppliers to global OEMs and start-ups.

> 36

years of EMC engineering experience

50

EMC Vehicle Test Systems delivered worldwide