Fluids are in, but also around vehicles. Their flow behavior and their effect on moving masses have an influence on driving dynamics, comfort, and durability.

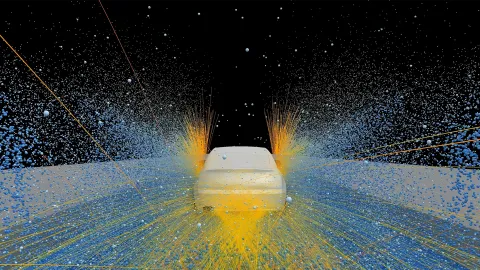

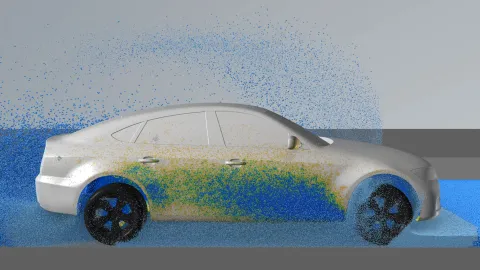

With the increase in cameras and sensors installed in the vehicle body, the draining of water and mud along the body takes on special importance. Passenger safety now directly depends on their reliable operation in all weather conditions. But there is no extra time available for development.

Cost Pressure

Physical tests require prototypes, are time and personnel intensive and thus costly.

Speed

Development time is not always balanced with development effort.

Accuracy vs. Speed

Optimization of one side is often at the expense of the other.

Advanced Simulation

The creation of CFD simulation models is complex and can therefore be very time-consuming.

Safety

Strict requirements for product functionality, quality, and safety must be met.

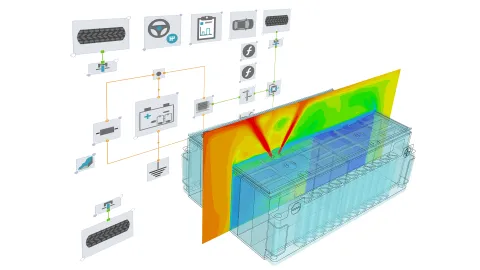

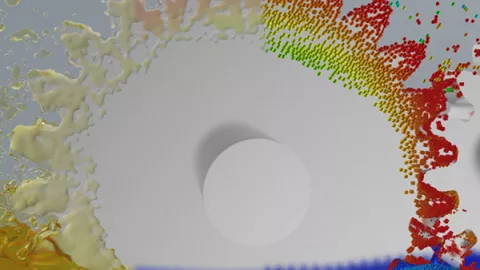

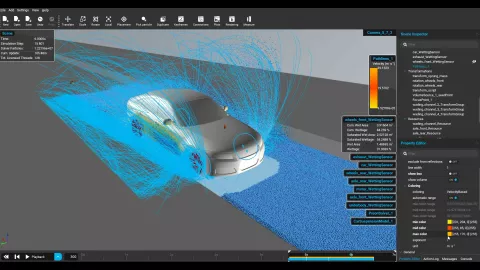

In contrast to classical CFD, the simulations in PreonLab are meshless. This not only simplifies model creation. It gives you short and powerful turnaround times when simulating Newtonian and non-Newtonian fluids. Regardless of whether you want trend analysis or precise predictions.

Ease of use was and still is particularly important in the development of the software. Thus, it was designed so that every user can use it intuitively in his daily work with a little training.

The goal has always been: to make development as efficient as possible without compromising on the quality of the results.

The advantages of PreonLab can be described in three words.

Reliability

Simulation matches reality. You get realistic motion of objects instead of simplified CFD setups.

Usability

Enabling intuitive work for everyone is at the forefront of development. All design decisions for GUI, workflows and functions follow this credo.

Efficiency

Short turnaround times are achieved with simulation. The simple handling saves additional time. The powerful software guarantees the most accurate results. Efficiency without compromising quality.

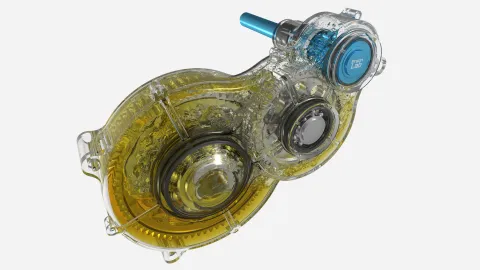

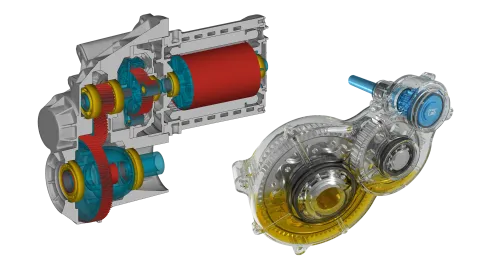

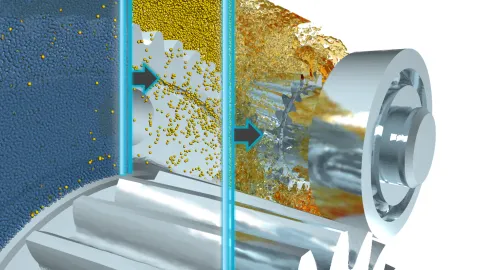

Gearbox

It is almost impossible to consider the oil distribution in a gearbox under realistic conditions. Due to the complex geometry and kinematics, simulation is also a challenge.

PreonLab changes that. STL files are imported in seconds. Workflows support you throughout the process. Whether you want to run a single-phase simulation for low rotational speed gears or a multi-phase simulation for high rotational speed gears.

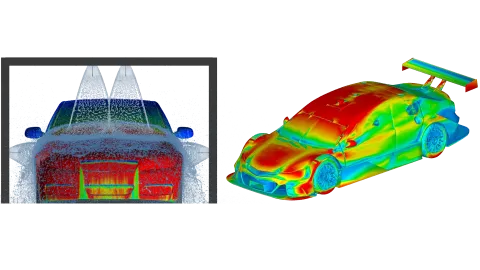

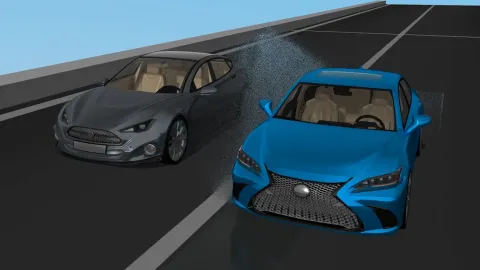

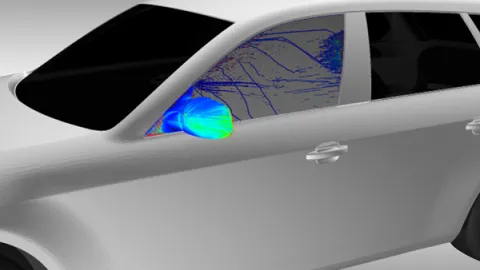

Vehicle Soiling

Rain, snow and dirt and their distribution. All these factors must be taken into account when designing the vehicle body and its functions.

With PreonLab you can take a closer look at an entire system or just individual parts. You do not need prototypes for this, just 3D data in the form of an STL file. This allows you to perform a full wetting analysis and evaluate the flow paths.

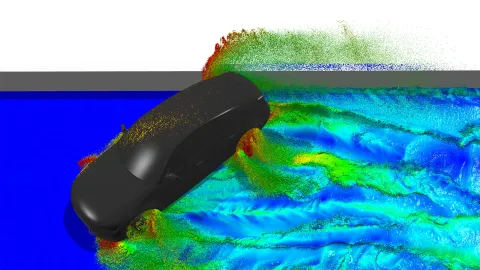

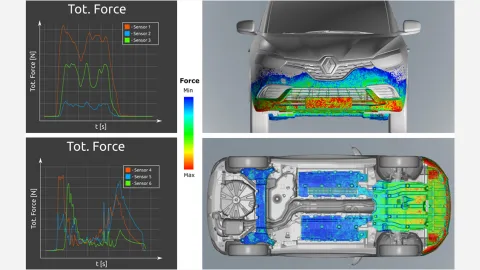

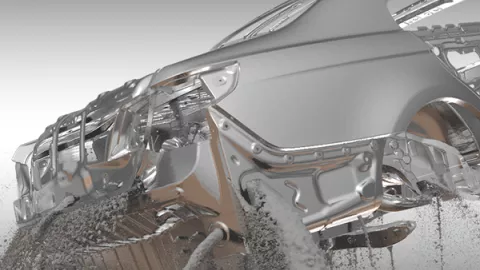

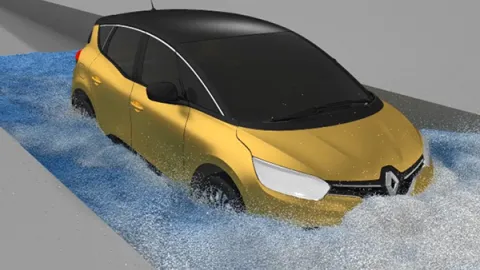

Water Wading

Water intrusion into a vehicle is always problematic.

By performing a full wetting analysis, measuring flooding heights, predicting underbody forces, measuring flow rates, and understanding the flow path, you can gain a lot of insight. With PreonLab, you can quickly test your designs against the metrics you need - without a prototype.

ATZextra – Mesh Free CFD Technology Revolutionizes Water Wading Analysis

Smoothed Particle Hydrodynamics (SPH) simulation is a promising mesh-free CFD technology that has revolutionized water wading analysis in recent years. AVL and Magna present a validation study that demonstrates predictive capability and efficiency of SPH-based virtualization. Leveraging virtual passenger car testing, development time and reliance on physical prototypes can be significantly reduced.

AVL Customer Case Study - Simulation-based Development of Functional Oil Distribution in Electric Axle Systems

Electric axle systems play an important role in vehicle electrification. Due to their compact design, they can be used in all vehicle segments with hybridized or all-electric powertrains.

AVL Customer Case Study - Water Wading Simulation

“Water wading” is a standard test in vehicle development. Water must not enter critical areas endangering e.g., battery packs, electric components or the air intake. Forces caused by the water should not damage the car body or float the vehicle.

AVL White Paper – SPH-Based Virtual Testing for Streamlined Vehicle Water Management

Efficient and safe water management is an important aspect of the modern vehicle development process, influencing not only durability and performance but also passenger safety and overall vehicle efficiency.