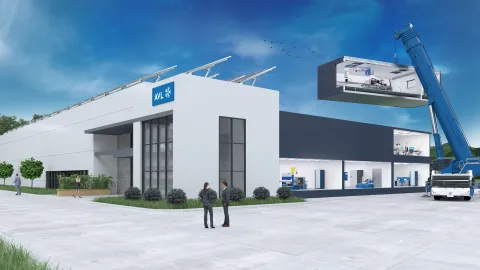

Our experts provide tailored solutions for both upgrading existing test facilities to meet capacity challenges and developing greenfield testing centers. We offer innovative modular testbeds in a containerized format as an alternative to traditional building methods. This approach accelerates project timelines, enhances planning quality, and ensures budget accuracy. Additionally, our advanced facility energy management solutions optimize energy consumption, lower operational costs, and contribute to sustainable testing environments.

Based on stakeholder input and market analysis, our experienced project team defines the essential functional elements of a project. We engage in continuous discussions with our customers to establish a shared under-standing of the project scope, ensuring alignment with technical and regulatory requirements. This foundation allows us to develop a compre-hensive concept and conduct a feasibility study, including compliance with governmental regulations and coordination with local authorities.

Detailed Design and Tender Specifications

Once the detailed design is finalized, we prepare tender specifications for potential suppliers. Our structured approach ensures that all technical and commercial requirements are clearly defined to prevent misunderstandings and streamline the procurement process.

Procurement Phase and Contract Management

During the procurement phase, we prepare commercial contract conditions and coordinate agreements with subcontractors or support our customers in doing so. Our focus is on securing the most suitable lab infrastructure and testing equipment at competitive conditions.

Execution Phase and Project Handover

Throughout the execution phase, we collaborate closely with customers, subcontractors, and the on-site team to ensure seamless project implementation. The project concludes with a structured handover, including all relevant documentation, ensuring a fully operational and future-proof test facility.

To ensure the highest quality and consistency in our architectural and engineering practices, we utilize a diverse set of methodologies and standards from renowned organizations around the world. Our approach is supported by references from the following authoritative sources:

-

UK: Royal Institute of British Architects (RIBA)

-

Germany: Honorarordnung für Architekten und Ingenieure (HOAI)

-

Spain: Real Decreto 2512/1977, del 17 de Junio. Tarifas de honorarios de los arquitectos (RD2512/1977)

-

Brazil: Instituto de Arquitectos do Brasil (IAB)

-

Europe/EU: Architects Council of Europe / Conseil des Architectes d’Europe (ACE-CAE)

-

US: The American Institute of Architects (AIA)

-

Global: Building Information Modelling (BIM)

By adhering to these standards and methodologies, we ensure that our projects are aligned with global best practices, providing our clients with the highest level of quality and professionalism.

AVL has decades of experience in designing, building, and operating test and development facilities. We offer our experience to you, starting with defining the ideal test environments, over design, construction up to qualifying your staff – for maximum effectiveness from day one.”

– Martin Steinbauer, Global Business Segment Manager, AVL List GmbH

Our credo for a vehicle test facility project is to create an optimal holistic solution. We support our customers in all project phases: from consulting, design, engineering, procurement, project execution and up to operation.

Consultancy

The goal of our consultation is to establish a shared understanding of the customer’s long-term product development strategy and the corresponding requirements for a future-proof test facility.

Through a series of structured workshops and information exchanges, we jointly define the expected market developments and future product portfolio. AVL contributes its global engineering expertise and industry-specific know-how to ensure informed decision-making.

Our consulting approach supports risk-aware planning and intelligent investment management – laying the foundation for a sustainable and scalable testing infrastructure.

Concept Generation

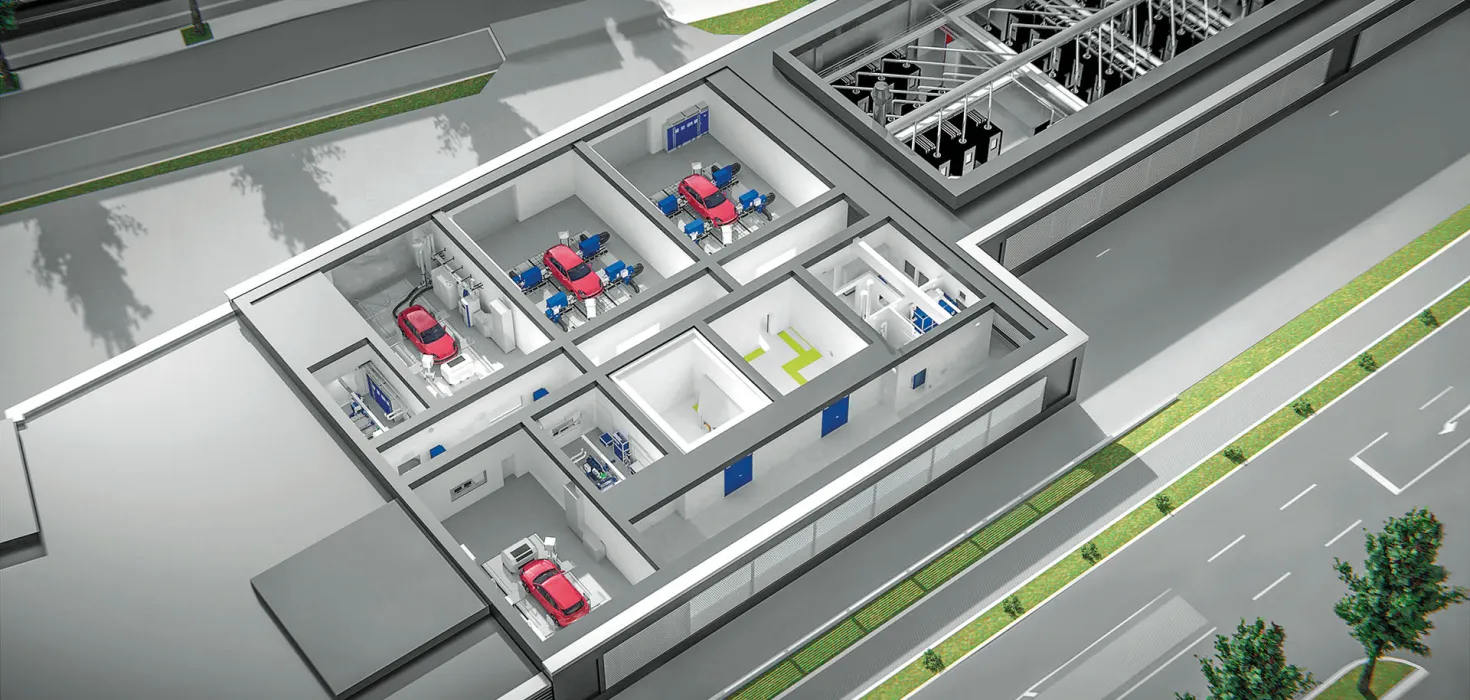

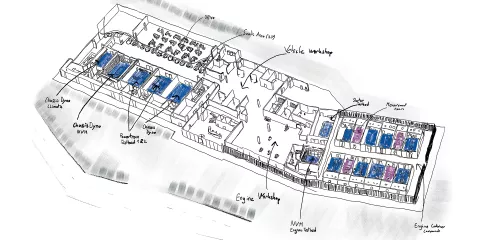

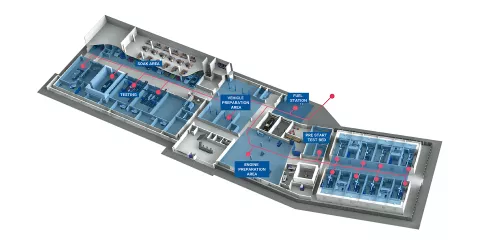

In the concept generation phase, the goal is to design a scalable and efficient tech center that aligns with the customer’s long-term product development strategy. Together with the customer, we define and refine the key functional elements required for a high-performing vehicle test facility or lab infrastructure.

We analyze all relevant boundary conditions – including available budget, project timeline, land size, and site layout. At the same time, we incorporate the latest advancements in development methodologies, digital workflows, and operational structures to ensure the concept supports both current and future organizational needs.

The result is a flexible, sustainable, and future-proof tech center solution that can grow with evolving demands – whether for combustion engine testing, battery test labs, or complete turnkey testing facilities.

Design Engineering

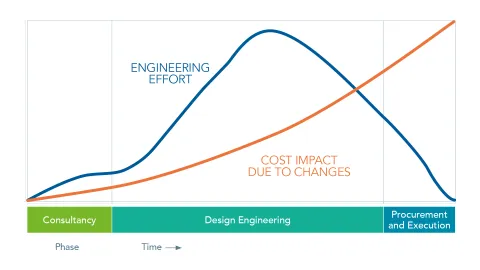

In the design engineering phase, the focus lies on developing a fully detailed tech center concept, including defined scope, project timeline, regulatory compliance, and cost framework. This stage lays the technical foundation for a successful vehicle test facility.

Designing such a facility requires deep cross-disciplinary expertise – covering building design, technical building equipment, fluidics, electrical systems, control systems, and safety infrastructure.

AVL supports this process with over 100 globally positioned specialists, providing complete system designs and planning documentation. These enable customers to initiate building permits, meet legal requirements, and collaborate effectively with local architects and engineers to realize the turnkey facility.

Procurement

Building a modern vehicle test facility requires high-end testing infrastructure and specialized systems, demanding trusted, experienced partners. During the procurement phase, AVL focuses on sourcing the most suitable equipment and materials under competitive market conditions.

We develop a tailored local procurement strategy, including a detailed logistics plan, vendor coordination process, and quality control procedures. All activities are aligned with the overall project implementation schedule, from lab equipment supply and construction start to vendor inspections, transport planning, and customs clearance.

AVL supports customers by defining precise technical specifications, selecting qualified partners, and ensuring that procurement and construction run smoothly as part of an efficient, cost-optimized turnkey solution.

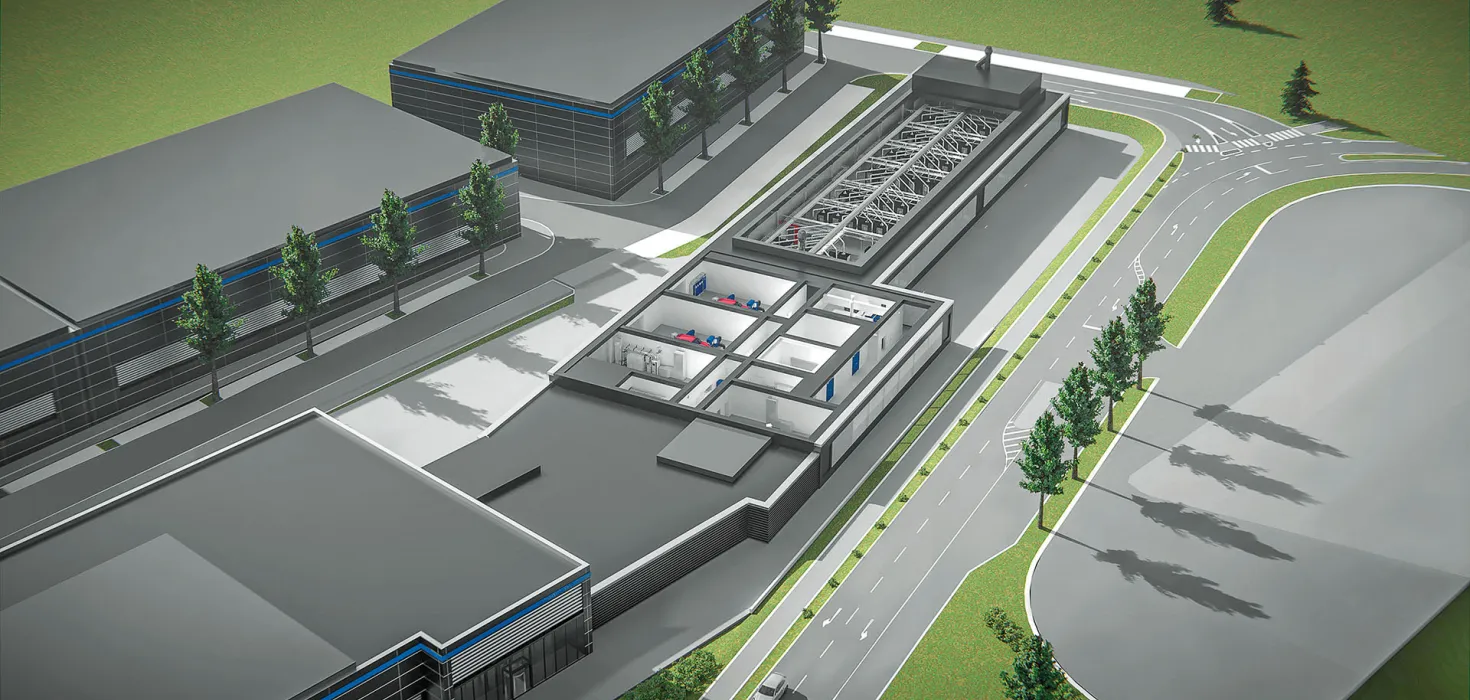

Execution

The objective of the execution phase is to bring the planned tech center to life – on time, on budget, and according to specifications. This phase includes off-site manufacturing, on-site construction, design adjustments, and close coordination between the customer, subcontractors, and AVL’s project team.

AVL oversees all key activities, including inspections, equipment installation, commissioning, and final acceptance procedures. Our proven construction management approach ensures full alignment across all project interfaces and stakeholders.

With more than 30 of its own vehicle test facilities and lab infrastructures built and operated worldwide, AVL brings unmatched expertise in managing complex turnkey projects. We appoint experienced project and site managers who ensure that every detail is executed efficiently and to the highest quality standards.

Service and Operation

The mission of a tech center goes far beyond providing infrastructure. It must effectively support the daily needs of engineering and testing teams. Ensuring the reliable availability of test systems, measurement equipment, and essential utilities is a core operational challenge.

But availability alone is not enough. A well-functioning service and operations organization must also manage test field planning, testbed operation and automation, data quality analysis, and infrastructure maintenance. These aspects are critical to maintaining productivity and performance in modern vehicle test facilities and lab infrastructures.

With experience gained from maintaining and operating over 7,000 global test installations, AVL delivers turnkey solutions for long-term testing facility services. We ensure that your tech center is not only built to perform – but also ready to evolve with your future testing demands.

From test facility consultancy and turnkey facility solutions to energy management and digital immersive reality solutions, you have come to the right place for tech center expertise.

Tech Center Consultancy

Investment decisions for tech centers should anticipate engineering demands for the coming decades. Starting a tech center requires knowledge of how the market will change and what products will be needed. It is important to be clear about any uncertainties because they greatly affect the Tech Center's design. AVL is well-placed to help because of our worldwide experience in planning and operating tech centers for many customers and diverse applications.

Turnkey Facility Solutions

Our turnkey facility solutions provide perfectly integrated test systems. Our holistic approach ensures complete solutions, including the integration of measurement and test technology into new or existing facilities. Moreover, we specialize in technical building equipment, such as ventilation, electrical installations, and sensors, as well as central equipment like transformers and switchgear. Benefit from our expertise in comprehensive testing infrastructure.

Energy Management Solutions

Sustainability and carbon neutrality are not only environmental factors, but also economic ones – saving and reusing energy is key to reducing operating costs. In addition, the increasing complexity of power interactions between test cells and the overall power infrastructure of a tech center requires processes and tools to understand how energy flows in the facility. AVL offers energy management solutions to design an efficient new lab, to upgrade existing facilities and software tools to monitor and control where and how the energy is being used in the tech center. We are committed to sustainability combined with meeting the highest technical, economical and quality demands.

Digital Immersive Reality Solutions

At the heart of digital transformation is immersive reality, which includes VR, AR, 3D scanning, and advanced 360° visualization – a critical force for improving efficiency and quality across the value chain. It enhances internal and external collaboration and improves performance in engineering, service, maintenance, and training. This technology facilitates the handling of complex projects, addressing crucial details such as space, piping, and design review throughout and after project execution. Whether in VR collision checks, design reviews, or AR maintenance guidance, immersive reality transforms task execution. By having a holistic understanding of what is needed and how this technology can support the entire process, we are able to create unique, custom tools and methodologies.

Testing as a Service

The AVL Test Factory provides comprehensive Testing-as-a-Service (TaaS) for propulsion system solutions, ranging from internal combustion engines to fully electrified and fuel cell systems. Leveraging state-of-the-art facilities, round-the-clock 24/7 operations, and over 70 years of expertise, we provide efficient, quality-assured testing and rapid data analysis via AVL Data Analytics. Clients benefit from a single point of contact for all testing needs, ensuring lean processes, fast trouble-shooting, and expert engineering consulting to optimize test planning and product development.

AVL Tech Center Solutions – Brochure

From Requirements to Reality.

AVL Tech Center Solutions – Whitepaper

Beyond the Test System: The True Scope of Investment.

AVL Energy Management Solutions – Whitepaper

Highly Efficient Energy Management for Test Facilities.

AVL Digital Immersive Reality Solutions – Booklet

Quality, efficiency, collaboration.

AVL is the global partner for the most efficient, flexible and reliable test solutions for all electrified vehicles, components and complete systems, using the most innovative technologies. We have been at the forefront of technology for more than 70 years and operate more than 260 testbeds in numerous company-owned Tech Centers worldwide. To achieve the highest efficiency from a test center, we support our customers with knowledge and gained experience. From requirements to reality – we make it happen.

60+

projects with turnkey responsibility

100+

specialized staff working worldwide

30+

owned and operating tech centers with over 300 testbeds