In the past, the process of establishing a test facility was relatively straightforward. The main objective was to develop internal combustion engines that would offer optimal performance, minimal emissions, and a rapid time to market. Today, however, the landscape has changed dramatically. The rise of diverse powertrain technologies demands more advanced and versatile test facilities.

Modern tech centers must now accommodate a broader range of powertrain technologies, including high electrical power requirements and various energy sources such as hydrogen (H2), ammonia, compressed natural gas (CNG), and methanol.

To address these evolving requirements, tech centers must be built with enhanced safety features and adaptable infrastructures. This ensures they can effectively support the development and testing of cutting-edge powertrain technologies while meeting all regulatory and safety standards.

Requirement Analysis

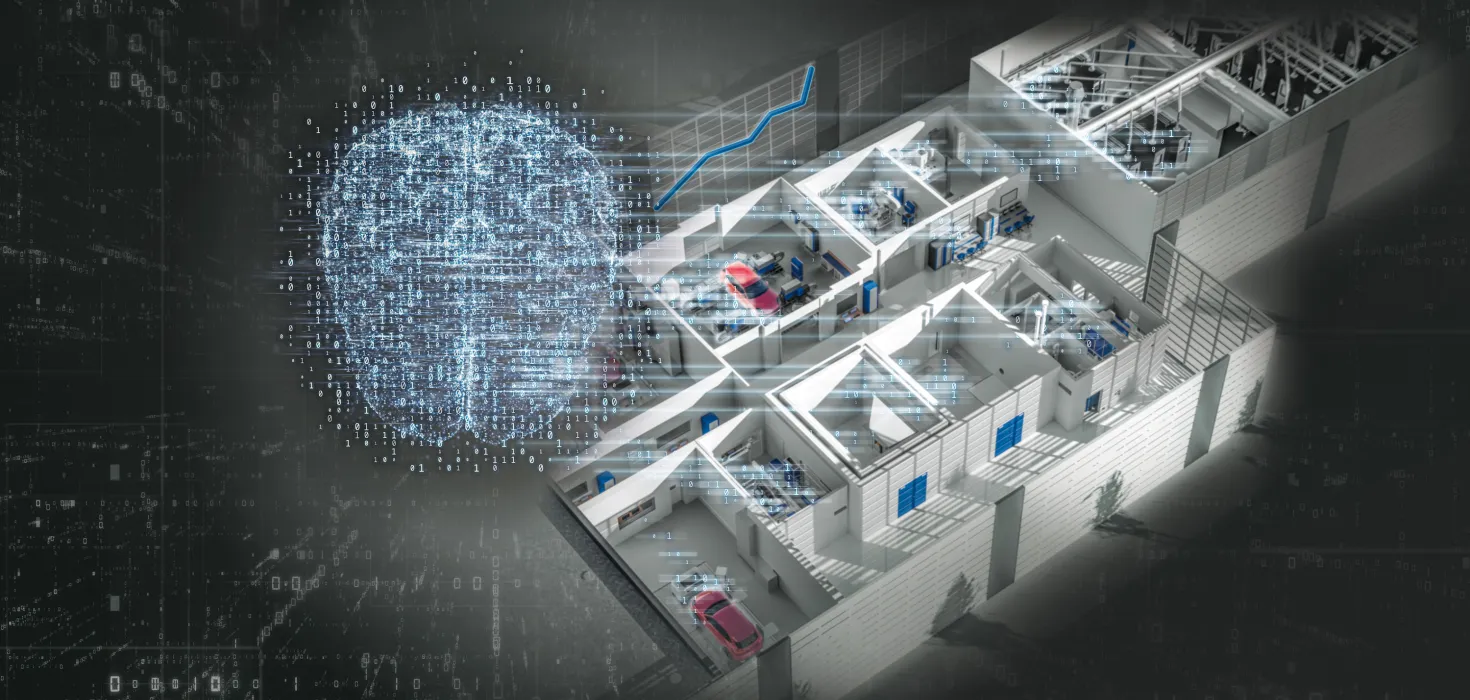

A requirements analysis consulting project leads to a clear and shared understanding of the product development strategy as a key input for the tech center planning. The customer's insights are complemented and compared with AVL's view, based on our experience gained in the numerous engineering projects we run worldwide, in a wide variety of applications and customer clusters. The input serves to elaborate the key functional elements of the tech center through a detailed understanding of the development needs and project constraints. In a further step, the conclusions lead to the identification of test system types and quantities, considering test methodology and virtualization.

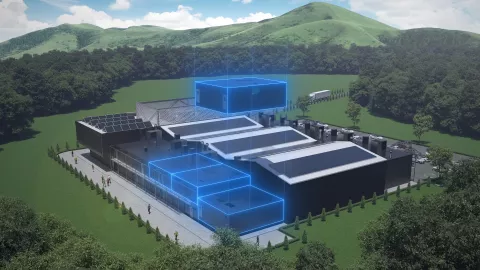

Concept Generation

Concept studies are a cornerstone of every major engineering project we undertake. Whether it's delivering turnkey solutions on greenfield sites or upgrading brownfield sites, our expertise guides our customers through the process of planning and designing their future tech center. A shared understanding of development and test requirements is translated into an optimally sized and sustainable test facility concept. We perform workflow analyses, design a layout, estimate construction costs, conduct environmental impact studies, calculate utility requirements, and evaluate project schedules, to name a few. This enables our customers to make the right investment decision in the early stages of the project.

Building a new test facility to increase testing capacity is a major investment. AVL is experienced in performing overall equipment effectiveness (OEE) analysis with our customers to get a clear picture of how well the existing test equipment is being utilized. A common conclusion is that only one third of its potential is being used. Therefore, before investing in additional test capacity, we recommend performing an OEE analysis and acting on the results before making a major investment in new test equipment.

Making the right decisions early in the design process is critical to timely project delivery and cost optimization. AVL's consulting and facility design engineering methodology addresses all key aspects of the Tech Center project lifecycle.”

– Geoffrey Gerring, Business Development Manager, AVL Ibérica S.A.

AVL Tech Center Consultancy offers significant advantages for companies investing in technology centers. Through thorough market analysis and our global experience, companies make informed decisions based on long-term needs. Customized design of technology centers, based on comprehensive needs analysis and concept development, ensures that they meet specific development requirements while taking into account future market trends. Utilization analysis enables companies to optimize resources by fully utilizing existing test equipment before investing in additional capacity, resulting in cost savings and more efficient resource allocation. In addition, AVL Tech Center Consultancy helps companies develop cost-effective solutions that meet evolving industry standards and safety requirements.

Benefits at a Glance

- Informed investment decisions based on market analysis and experience

- Customized design of technology centers that meet specific development needs

- Optimization of resource utilization through OEE analysis and efficient use of existing test equipment

AVL is the global partner for the most efficient, flexible and reliable test solutions for all electrified vehicles, components and complete systems, using the most innovative technologies. We have been at the forefront of technology for more than 70 years and operate numerous company-owned tech centers worldwide. To achieve the highest efficiency from a test center, we support our customers with knowledge and gained experience. From requirements to reality – we make it happen.

45

Global Tech and

Engineering Centers.

11

Percent of Turnover

Invested in Inhouse R&D.

315

Testbeds Operated Worldwide.