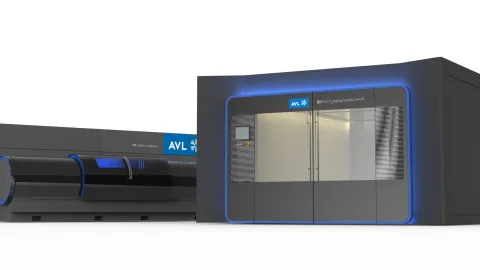

To meet the demands of OEMs and their customers, batteries must balance performance and durability. High assembly quality is essential in all areas, including the cooling system, battery pack housing, module coupling, battery management system, and high-voltage connectors. The Battery TS™ End of Line ensures seamless integration, compatibility, and compliance with the highest automotive standards. Leveraging our extensive R&D experience, we’ve developed an EoL solution that optimizes test cycles, reducing both cycle times and costs. Highly reliable and efficient, the Battery TS™ End of Line is accurate, robust, and versatile, making it suitable for a wide range of battery applications.

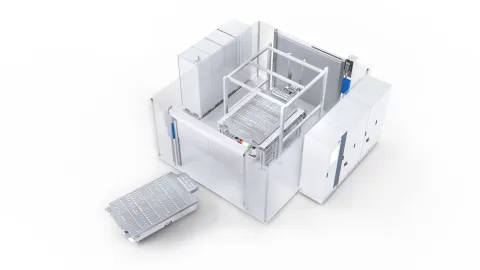

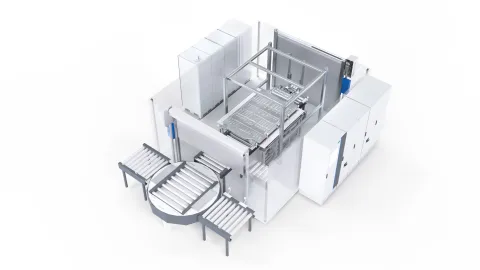

The modular design is highly adaptable, making it suitable for all types of assembly lines and production volumes, ensuring flexibility in various manufacturing environments.

It offers a versatile configuration that can easily accommodate different types of battery modules and packs, providing the necessary flexibility to meet the diverse needs of modern battery production.

With the ability to test multiple batteries in parallel, this solution optimizes both the physical footprint and energy consumption, enhancing overall operational efficiency. Additionally, the system is equipped with state-of-the-art test libraries, ensuring high-quality, precise testing in line with the latest industry standards.

|

Longstanding Experience

Innovative and reliable tools enable intelligent failure analysis, production data analysis and provide automation features for easy operation.

Fail-safe Approach

Safety, functional, and performance testing are possible, and an open architecture allows integration of devices into third-party assembly lines. A fail-safe approach ensures reliability and provides peace of mind.

Customized Solutions

We can tailor our systems to meet your specific needs and development methodology. In addition, our local service teams can provide training, service, troubleshooting, and maintenance to ensure return on investment.

Customizable and Robust Automation System

With AVL PUMA 2™ Production, the user can quickly and easily adapt the user interface and the test procedures to his tasks and needs without any programming knowledge. The automation includes a mechanism to check, compare and log any changes.

Testing Procedures

The AVL testbed supports a wide variety of tests:

- Safety tests: Potential equalization, insulation resistance test, dielectric strength test, HV interlock, etc.

- Functional and performance tests: BMS tests, housing/cooling integrity check, capacity check, DCIR tests, SOC checks, etc.

Multiple Battery Support

EOL test systems support multiple batteries to optimize footprint and energy consumption. Batteries can be tested independently for easy maintenance and flexibility on the production line.

Why develop the most powerful battery if you can’t guarantee its quality and durability? At AVL, our mission is to cover the entire development process, from R&D to EOL, with efficient and reliable tools you can rely on."

– Matthieu Clauet, Department Manager, AVL List GmbH

AVL E-Mobility Testing Solutions – Brochure

From battery to full vehicle, from products, to test systems to whole test facilites – learn how we can support your testing needs.

AVL Production Testing Solutions – Brochure

Quality in Time.

AVL Battery TS™ EOL – Solution Sheet

Improve production efficiency and avoid costly recalls.

Production Testing with Big Data – Whitepaper

How to Turn Production Testbed Data into Valuable Insights with AI