Mastering Vehicle Testing Challenges on Chassis Dyno

Developing modern vehicles—whether Battery Electric Vehicles (BEV), Hybrid Electric Vehicles (HEV), Fuel Cell Electric Vehicles (FCEV), or Internal Combustion Engine (ICE) platforms—requires navigating increasing complexity and pressure. AVL supports you in overcoming key challenges:

Balancing Cost, Speed and Quality in Development

Real-world testing for climate, altitude, Noise, Vibration, Harshness (NVH), Electromagnetic Compatibility (EMC), and endurance nevertheless is essential—but costly and time-consuming when performed on-road. Restricted budgets lead to fewer prototypes available, therefore validating new technologies demands smarter approaches and flexible, future-ready testing environments.

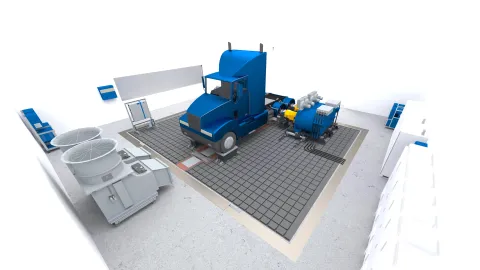

Our vehicle test systems are designed to validate and test a wide range of vehicle types, from motorcycles to 6x6 heavy-duty trucks, covering various velocities, forces, power classes, and voltage and current levels for electrified vehicles. The testbeds simulate vehicle velocity and force, replicating real-world driving conditions, road data, or time-lapsed testing scenarios.

With an optimized hardware and software toolchain, our systems significantly shorten the design and validation process, allowing for faster setup and execution in a reproducible lab environment. These test systems reduce the need for on-road testing, minimizing time, risk, and costs.

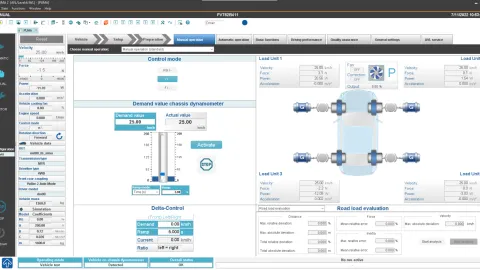

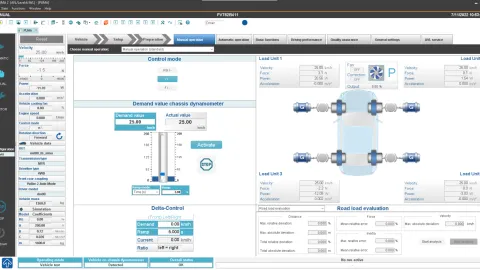

Leveraging the AVL PUMA 2™ automation software platform ensures synchronized measurements and consistent data from all integrated devices. This high level of data quality, combined with precise measurement, control, and simulation capabilities, guarantees exceptional measurement precision.

All calculations and protocols, as well as measurement results, are approved by leading authorities, and our systems can be certified according to ISO 17025. As a result, testing outcomes using AVL vehicle testbeds are fully recognized and accepted by authorities, including for range or COP testing.

During this period of time, which is characterized by disruptive changes on an unimagined scale, with changes being far from complete, AVL vehicle test systems are THE reliable and proven solutions when it comes to final vehicle validation and compliance testing according to the latest legislations, from range testing up to EMC test for type approval.”

-- Roland von Gavel, Head of Business Development, AVL Zöllner GmbH

We offer a full range of services and add-ons to maximize testing performance and ensure compliance.

- Chassis Dyno Consulting (in-house experience)

- Modernization: Extend the lifetime of your chassis dynamometer with upgrades for state-of-the-art accuracy and compliance.

- ISO/IEC 17025 Calibration: Certified calibration and re-calibration services ensuring highest measurement quality and global compliance standards.

- Ramp-up Support, Maintenance – global

- Training, application Support (optimization)

- Professional global service

- Turnkey Solutions

AVL Chassis Dyno Solutions – Brochure

The Road in Your Lab.

AVL E-Mobility Testing Solutions – Brochure

From battery to full vehicle, from products, to test systems to whole test facilites – learn how we can support your testing needs.

AVL Roadsim™ NVH – Solution Sheet

You can hear the perfection.

AVL’s automation platform PUMA 2™ represents the brains behind many different testbed applications. Our leading automation system is easily extendable to suit modern testing methods.

VECON 2 is our premier chassis dyno automation and control system, ensuring top-tier testbed quality in compliance, data accuracy, control, and usability. It enables highly realistic vehicle testing, which is especially crucial for electrified vehicles. Integrated with the complete PUMA 2 Vehicle solution, it offers a consistent, adaptable toolchain. Its extensive features enhance flexibility and optimize testbed utilization.

Realistic Vehicle Testing Under Controlled Conditions.

The AVL Vehicle Powertrain TS™ enables full-vehicle testing under realistic environmental and driving conditions. Wheel hub dynamometers simulate road loads with high precision and repeatability – even during dynamic driving maneuvers.

Transform your e-mobility analysis with AVL CONCERTO 6™, featuring fast data access, AI-driven technologies, advanced visualizations and calculations, and auto-generated reports for superior performance and precise insights.

AVL iGEM 2™ is our cutting-edge test automation solution for your energy and emission testing needs. It delivers high-quality data for certification and R&D testing.

AVL Vehicle Testbed Automation & Control is our automation system for chassis dyno vehicle testing

AVL Vehicle Testbed Automation & Control is our automation system for chassis dyno vehicle testing

DRICON is a flexible, modular robotic solution designed to transform vehicle testing. Our solution covers emissions, durability, and range testing with high precision, consistency, and effortless integration into existing test setups.

Learn more about our software solution to monitor, track and log vehicle charge events.

The AVL Customer Services organization consists of more than 700 service- and application engineers worldwide, operating from more than 50 locations. Our global footprint is your local benefit.

AVL’s comprehensive worldwide network of experts allows best customer vicinity, ensuring consistent and connecting testing fields globally. Wherever your R&D challenges take you, we are always close at hand, ready to provide the service you need.

> 65

years of experience in the area of vehicle test systems

> 1,400

vehicle test systems delivered