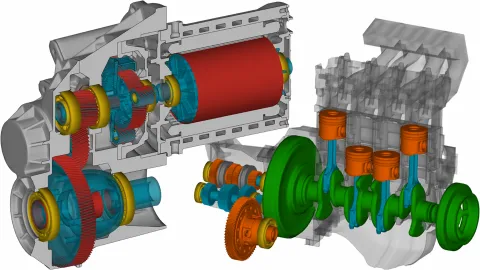

Optimizing the NVH and durability of powertrain systems requires an accurate understanding of their dynamic behavior. EXCITE M enables engineers to model, simulate, and analyze the complex dynamics of powertrain components with exceptional accuracy. The software handles the real-world behavior of flexible bodies that move, deform, and interact with contacts like gears and roller bearings or lubricated contacts, such as oil film bearings and via electromechanical and signal interaction.

Unlike conventional tools that address individual effects separately, EXCITE M simulates all interactions simultaneously – just like in real-world conditions. The tool captures key factors like contact dynamics, structural deformation, and lubrication effects, ensuring a complete and realistic picture of the powertrain’s performance.

With EXCITE M, engineers can quickly build detailed models, validate designs, and predict potential issues in a virtual environment. Whether it is gear sets, crankshafts, or piston-liner interactions, the software enables faster and more accurate decision-making, reducing the need for physical prototypes and minimizing time-to-market.

Cost Pressure

Physical tests involve prototypes, increasing time, effort, and development costs

Time-to-Market

Short development cycles demand fast system validation to meet performance targets without delaying production

Powertrain Complexity

Growing complexity between mechanical and electric systems and control signals calls for smarter solutions to handle these interactions

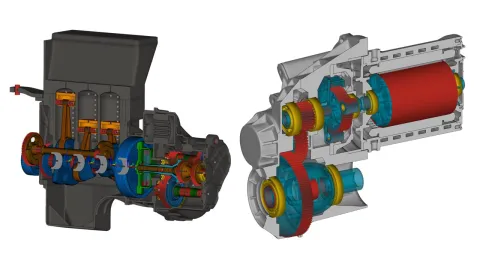

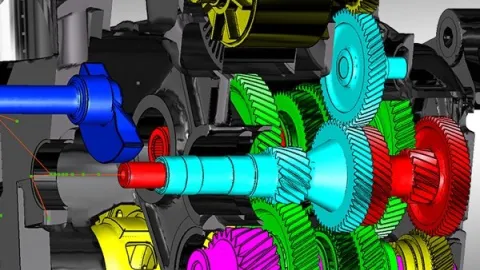

Start by defining the geometry, using rigid bodies and linking components such as plain or roller bearings, gear pairs, cranktrain components, and many more. This allows for the quick creation of simulation models.

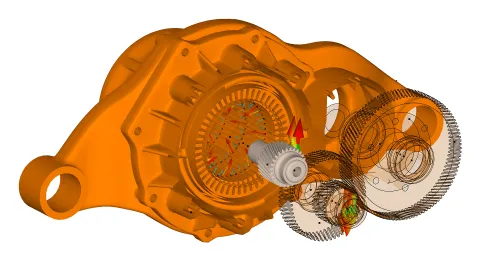

With the integrated Component Modeler, users can seamlessly prepare advanced finite element models and generate flexible bodies. Fully integrated assemblies, such as planetary gear sets or cranktrains, simplify the setup of complex dynamic systems. The interaction between components can be verified through kinematic calculations and animations, ensuring accurate modeling before proceeding to the simulation phase.

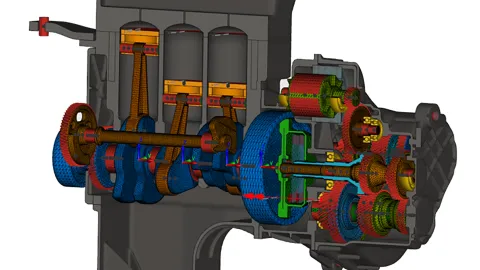

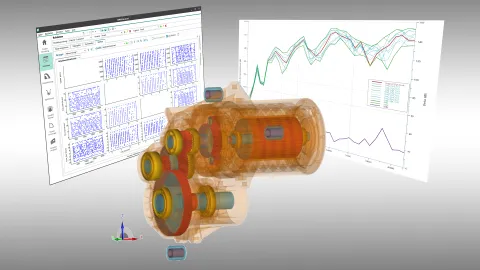

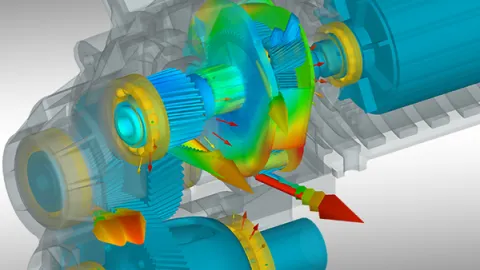

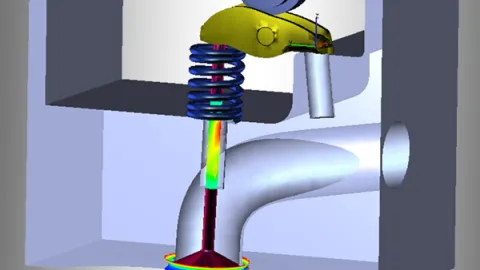

The software offers a choice between fast frequency-domain analysis for quick assessments and non-linear time-domain analysis for detailed investigations. Body motions and deformations at any position can be assessed as a diagram, a 2D plot or 3D animation. As well as any interaction between the bodies, like force or moment. Users have the option to request special results like gear contact patterns or the pressure in the oil film bearings. For series calculations Campbell diagrams are automatically generated.

EXCITE M integrates seamlessly into existing workflows, supporting a multidisciplinary approach that covers everything from mechanical systems to electromechanical interactions. Whether your focus is on reducing noise or improving durability, EXCITE M provides the tools to achieve your goals with precision.

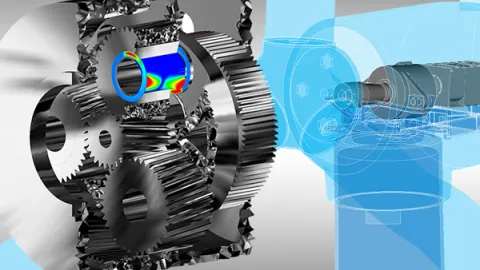

Accuracy

By using detailed physical models and solving complex interactions simultaneously, the software delivers high-fidelity results that reduce the reliance on costly physical prototypes. This significantly shortens the development process while ensuring the highest quality output.

Multilevel Approach

There are different modeling depths for the individual components and the overall system, providing a balance between accuracy and simulation time. The simulation models can be extended and further detailed during the development process.

Modeling Efficiency

The EXCITE M solver was designed for performance from the start. This allows users to conduct detailed investigations of specific phenomena in a timely manner. Built-in tools like the REXS interface to the FVA-Workbench or the E-Motor Tool streamline model preparation.

NVH

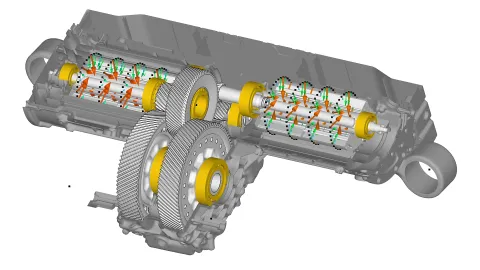

One of EXCITE M's core competencies is the calculation of structure-borne and airborne noise of powertrain units. Evaluation tools such as Operational Deflection Shape, Numerical Transfer Path Analysis and Modal Contribution Factors provide answers to the causes and sources of excitation and vibration.

Tribology

The influence of friction, lubrication and wear under dry and lubricated conditions is essential in many areas of technology. With the help of EXCITE M you can reduce friction, optimize wear and thus increase the durability of bearings and components and reduce energy consumption.

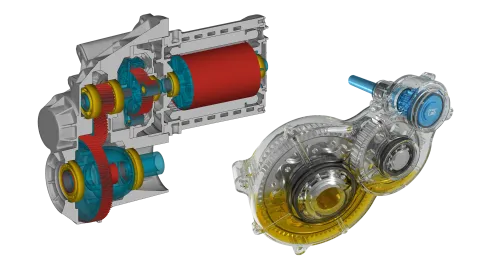

Electro-Mechanical Interaction

The e-motor is a major source of tonal noise in an e-drive. EXCITE M is capable of predicting this noise for PMSM, SCIM and EESM. The electromagnetic forces depend on operating conditions, speed, rotor misalignment and controller settings – all of which can be taken into account within the simulation software.

The influence of Pulse Width Modulation on the stator forces and rotor torque is also considered.

Durability

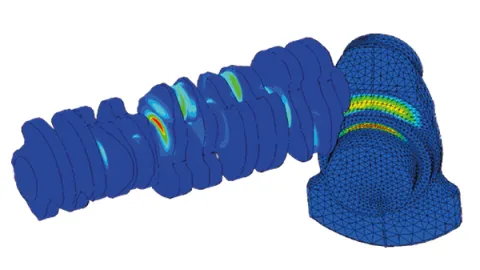

EXCITE M is able to accurately predict body forces and their deformation. This information is fed over time into the Finite Element (FE) and fatigue tools, which provide stress and life predictions for key components such as crankshafts.

We deliver a streamlined workflow that integrates the EXCITE M tools to obtain the dedicated inputs for the FE and fatigue tools.

AVL White Paper – AVL E-Motor Tool™ – Bridge the Gaps in E-Motor Development Workflow

Development processes that rely heavily on simulation have been honed over time for conventional powertrains, but they could also be applied to e-drive development. However, some gaps specifically related to the e-drive development, must be bridged to ensure a smooth development process. This whitepaper demonstrates how the innovative E-Motor Tool supports e-drive development.

The AVL E-Motor Tool™ - Easily Parameterize the E-Motor Emulator for Inverter Testing

E-Motor Emulator is used for the physical testing of the inverter removing the need for a physical e-motor. With AVL E-Motor Tool it is possible to effortlessly design a customized e-motor tailored specifically to your inverter testing needs. The precise set of parameters for this e-motor are provided to the E-motor Emulator in one click.

AVL Customer Case Study - EHD Bearing Simulations on WinGD 2 Stroke Engines

Increased demand to minimize cylinder distance for new twostroke, low-speed marine engine developments, including new engine structure concepts and design-to-cost approach, result in an increased need for EHD calculations of WinGD`s main bearings.

Find out how our multi-body dynamics simulation solution AVL EXCITE™ helped WinGD to successfully deal with this challenge.

AVL White Paper – Predictive Transmission NVH Analysis for ICE Based and Electrified Powertrains

Download our white paper to discover how simulation can be applied to optimize key powertrain NVH attributes, extending classical IC engine NVH to modern powertrains including highly complex transmissions and electrified powertrains.

AVL Customer Case Study - NVH Simulation at Deutz

Legal constraints which impose ever stricter emission limits are forcing engine manufacturers to drastically reduce the sound emission of their products. In addition, increasing end customer expectations require a greater focus on the acoustic behaviour of an engine.

AVL Customer Case Study - System Simulation in BEV Development at EDAG

For battery electric vehicles (BEV), the high-voltage storage unit is the crucial component in terms of performance, efficiency and range. To optimize these attributes extensive investigations are required. Both in the overall vehicle context and under different, sometimes extreme boundary conditions.