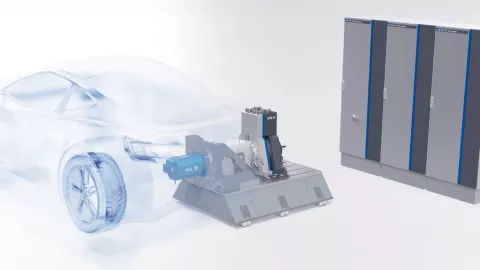

Ensuring that the performance, efficiency and drivability of your e-drive perfectly matches the vehicle requires extensive testing and optimization. The AVL E-Motor TS™ Performance system, including software packages and ready-to-use applications, allows you to quickly develop, test and validate your e-drive to the highest quality standards.

Our system serves as a comprehensive environment for the development, testing, verification and validation of electric drives, focusing on electrical, mechanical and thermal characteristics. With our proven software toolchain, it optimizes electric drives for maximum efficiency and NVH performance. The AVL E-Library enhances the validation process with automated test reporting, while ISAC and VSM offer precise tuning and validation for real-world vehicle operation.

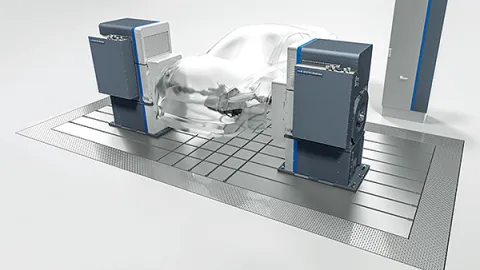

To stay ahead of future developments, our standard AVL E-Motor TS™ Performance solution includes a high-speed capability of 25,000 rpm. We offer a range of additional features to enhance your e-drive testing and optimization:

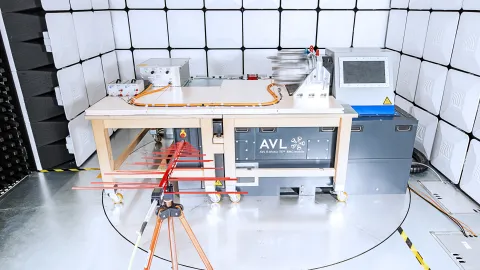

- AVL PUMA™ Automation System: Facilitates automation, simulation, real-time processing, data recording, and storage, among other functions.

- AVL CAMEO™: Specialized for optimizing e-drives.

- Dyno and Mechanics: Designed for high-speed and high-torque applications.

- Modern SiC Dyno Control Cabinet: Provides optimal control performance.

- High-Accuracy E-STORAGE Battery Emulator: Ensures precise battery emulation.

- AVL X-ion™ Power Analyzer: Includes the e-Power toolbox for various applications.

- AVL Universal Inverter: Supports e-motor development and tuning.

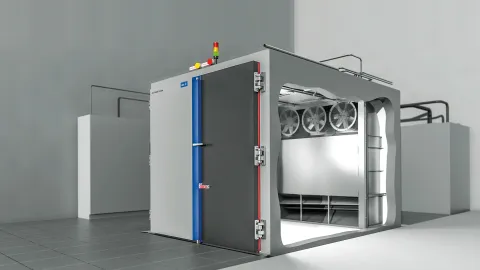

- Climatic Chamber and Coolant Conditioning Unit: For performing climatic tests.

- AVL Dynamic Torque Transducer: Analyzes e-drive NVH, optimizes control, and enhances simulation accuracy.

This comprehensive suite of features ensures that your e-drive testing and development are future-proof and of the highest quality.

| Technical Details | |

|

AVL PUMA 2™ |

E-motor GUI, 10kHz realtime system, |

|

Dynamometer |

Speed 25,000 rpm, torque up to 1200 Nm |

|

E-STORAGE™ SiC |

1200 V |

|

SPECTRA™ Universal Inverter |

switching frequency 2 – 96 kHz, |

|

AVL X-ion™ |

up to 12 Msamples, NVH measurements, |

|

Coolant conditioning system |

–40 to 130 °C |

|

Climatic chamber |

–40 to 150 °C |

|

Dynamic Torque Transducer |

± 3,500 Nm | 25 kHz | 0.5 % accuracy |

Specific Software Products

for E-Motor

With AVL PUMA 2™ automation, AVL CONCERTO™, and the e-power toolbox, AVL delivers several e-motor-specific software products for speeding up the development process.

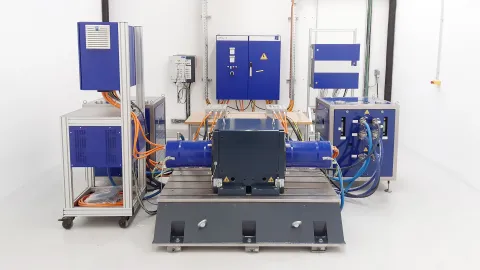

Mechanics for a Wide

Range of UUTs

The mechanical solution is optimized for high-speed and high-torque applications, and is the perfect basis for covering any test cases with different UUTs.

Toxic Torque Analysis

Clear determination of torque and forces which are not dedicated to propulsion for accelerating your e-motor development.

To truly unlock the potential of electric drive systems, we must embrace the future with unmatched precision and innovation. That's where our cutting-edge technology meets the evolving demands of electric power to deliver exceptional performance and reliability. In this way, we're redefining what's possible in e-motor performance."

– Mario Propst, System Line Manager E-Drive, AVL List GmbH

AVL E-Mobility Testing Solutions – Brochure

From battery to full vehicle, from products, to test systems to whole test facilites – learn how we can support your testing needs.

AVL E-Motor Testing Solutions – Brochure

Validate e-motors of different types, speeds, and torques.

AVL E-Motor TS™ Performance – Solution Sheet

The test system for developing your unique e-drive.

AVL E-Motor Testing Solutions – Application Sheet

An overview of our solutions on 2 pages.

Customer Use Cases

Compiled key use cases of the Universal Inverter.