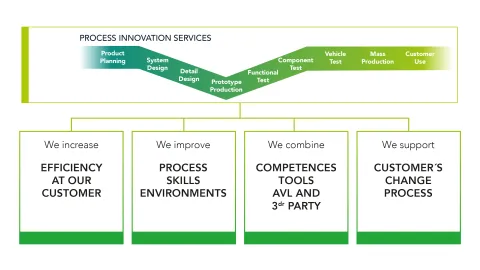

Development efficiency has always been at the heart of what we do. Improvements can be made in three areas - your development, lab and IT processes, your employees' skills and your existing development environments. The key is building the right skills and combining them with the right tools. We accompany you on this journey from discovering potential for change all the way through implementation.

AVL’s Process Innovation Services help you meet today’s demands. With our consulting and implementation services, you develop a more competitive product portfolio, optimize your development process and improve the efficiency of your simulation and test factory. AVL is in a unique position to help. With our deep understanding of vehicle development, methods and tools, you’re able to improve your development efficiency drastically. We will help you make the right decisions in today’s challenging, rapidly changing development ecosystem.

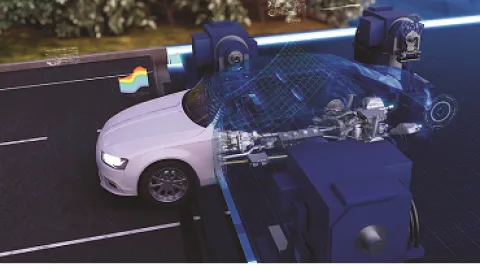

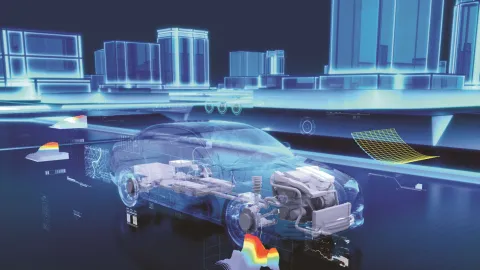

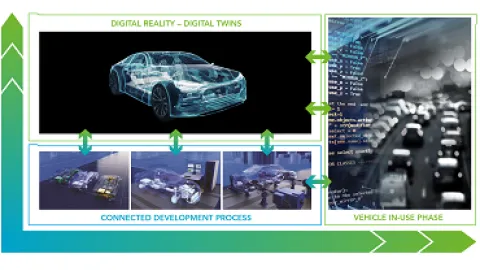

We develop CONNECTED Toolchains as standard methodologies that combine testing, simulation, data management and technological know-how to increase the efficiency of a development process in terms of quality, time and cost. By means of efficient “frontloading”, engineering tasks are shifted from expensive prototype testing on the road towards early development phases in a partly virtual environment. Our CONNECTED Toolchains cover a variety of different automotive development areas, ranging from conventional powertrain applications to electrification and from component to system to vehicle level.

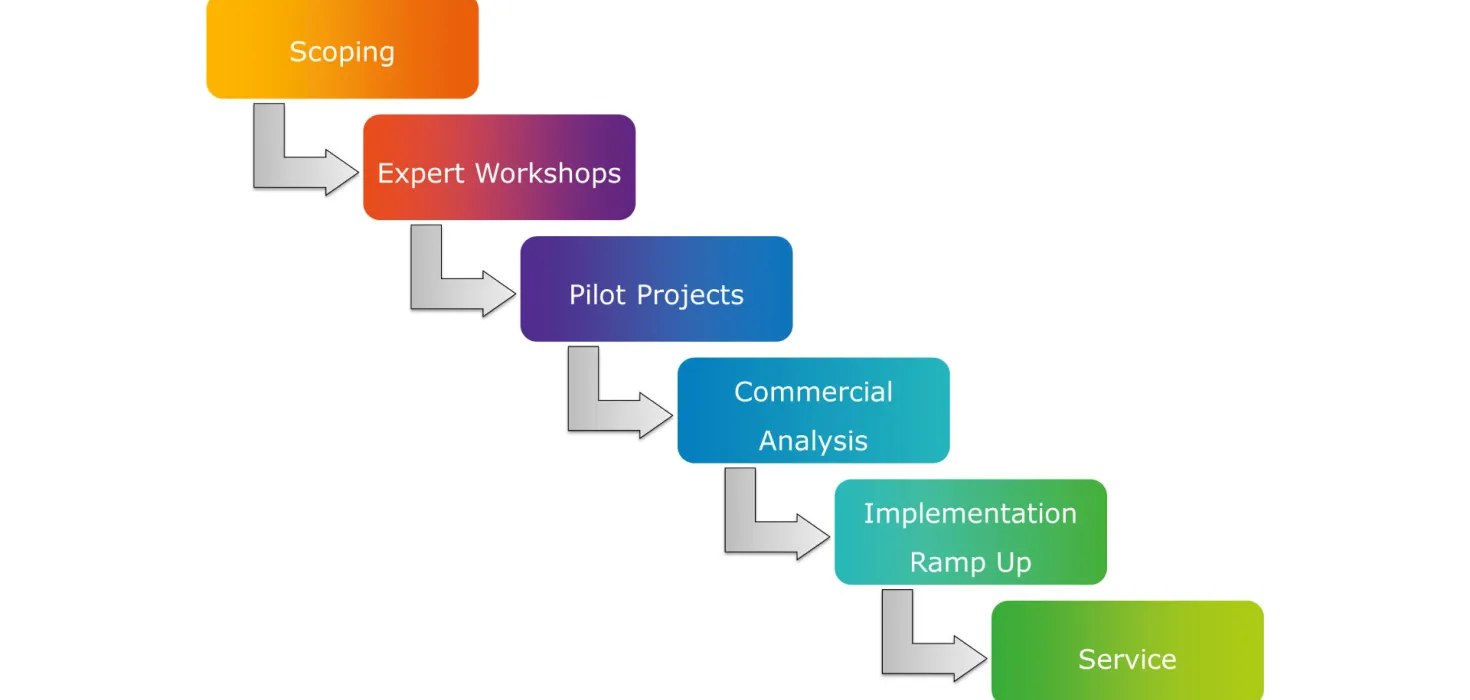

Because our service is comprehensive, we do not just help you scope and plan particular changes. Unlike a traditional consulting service, we take it a step further: With proof-of-concepts (PoCs) and pilot projects, we show you how these adjustments can bring measurable and significant improvements. Together, we create a roadmap, and we will implement it into your processes so that your engineers can use the new capabilities in the most efficient and effective way.

Combining customer processes and business know-how with AVL’s international experience and innovations assures measurable improvements in customer processes.

- Rainer Schantl, Chief Engineer Process Innovation and Implementation, AVL

- Increase development efficiency

- Shorten time-to-market

- Reduce costs and increase quality with a higher degree of virtualization

- Shift to a software-centric and data-driven approach

- Solve tasks with the right mix of development environments and tools

Highlights

Moving steadily into the future: Find out what’s brand new in the field of process innovation.