Make use of our expertise in propulsion system development and integration, which also allows us to reliably assess the interactions with other systems – a significant advantage for the functional and software-oriented consideration of your vehicle as an overall system.

We can help you optimize your vehicle development on all levels: In doing so, we assist you in perfecting both the actual vehicle and its connectivity – with the driver’s everyday life and their surroundings while driving.

Complexity of Subsystems

The premium vehicle segment is a trailblazer for many innovations – from steer-by-wire and rear axle steering, to torque vectoring for electric all-wheel drive systems (eAWD) and electromechanical roll stabilizers and modern multi-chamber air suspension. These subsystems will gradually also make their way into volume models. They must be functionally defined, developed, calibrated, and considered collectively to ensure they meet the statutory requirements, the demands of automotive manufacturers, and the expectations of end customers.

We take care of intelligently combining control units into a global vehicle controller for you. Our comprehensive approach with expertise in all necessary aspects of software and hardware is crucial added value here.

New Kinematics Interpretations

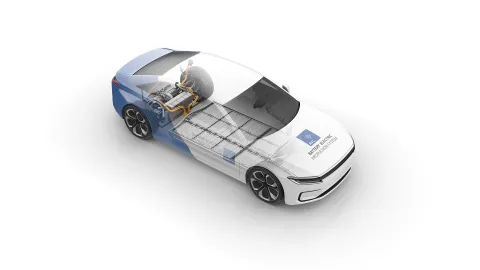

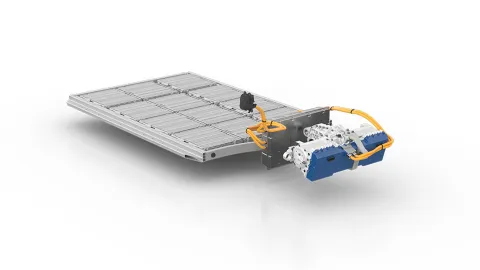

New, electric drive systems have numerous implications for the geometry of the vehicle – from changed design limitations to a lower center of gravity since batteries are usually installed in the base.

We assist you with the complex task of aligning vehicle kinematics with these new parameters. For example, if an e-axle needs to be integrated into a hybrid vehicle, we factor in the effects on the rear axle as well. This enables wheel control, driving dynamics, and comfort features to be maintained. We aim to get the maximum out of all desired driving characteristics – at manageable costs.

Our chassis service ranges from the initial concept phase to the start of production. One of our greatest assets is the virtual assurance of all systems with our toolchain at a very early stage of the project. For this purpose, we have enhanced proven programs such as AVL VSMTM (simulation) and AVL CAMEOTM (calibration) – whose origins lie in propulsion system development – with specific functions relevant to the chassis.

The desired driving functions and the related technical criteria can be derived from our extensive benchmark tests. We are happy to take care of requirements management through to release recommendation for you as well. On request, we will also help you select a suitable supplier.

How will this car drive at the end of the day?

We always answer this question project specifically with focus on objectives at overall vehicle level.

- whether we are responsible for performance, drivability, energy/fuel-consumption in all driving modes of a sporty premium car

- or on the driving dynamics, traction and stability functions of a new BEV on-or offroad vehicle

– DI Erik Bogner, Skill Area Manager Vehicle Driving Functions & Systems at AVL

- Two-pillar principle: We combine expertise in all classic hardware areas of the chassis with knowledge of all software-based driving functions.

- Frontloading: Simulation-based methods enable us to illustrate driving characteristics realistically at a very early stage. This allows important technology decisions to be made earlier on.

- Assurance: Our comprehensive toolkit has proved itself in numerous projects. We also use this in-house continuous toolchain for all chassis aspects.

- System expertise: Our well-founded knowledge means we never look at isolated vehicle functions, we always consider the interaction with all other areas of the overall vehicle.

- Independence: A huge range of chassis components is available. As an independent partner, we have the necessary overview of the competition and the market. This allows us to provide unbiased advice and to select the best solution for you.

All vehicle disciplines are linked optimally in our global network of engineers and scientists. We offer outstanding expertise in handling simulation platforms for the most relevant software tools that are used in thermal management. Wherever you are located – we can provide on-site support directly.

News

Moving steadily into the future: Find out what’s brand new in the field of functional vehicle development.