The greatest challenges for the development of combustion engines today arise from the transition from pure combustion engine to hybrid drive.

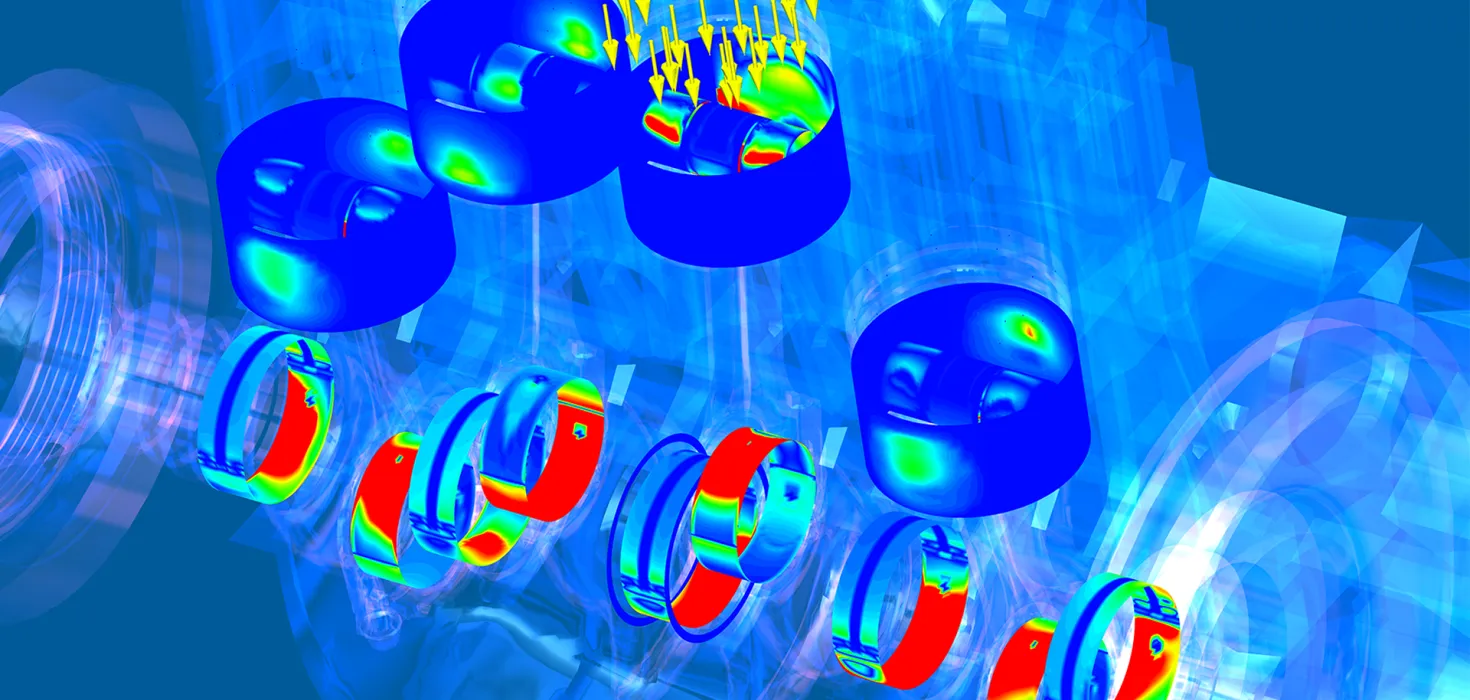

The combination of combustion engine and electric motor leads to a number of new operating conditions. For example, additional loads are also transferred to the crankshaft drive via the coupled e-motor, which places greater stress on the crankshaft bearings. The combustion engine is temporarily switched off while driving, it cools down, but must later deliver high power in a cool state.

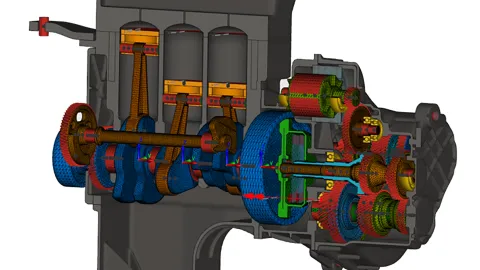

Our approach at AVL: Our software solutions have been extended to the extent that they can also represent the electric motor in a high level of detail, combined in a single simulation model together with the

combustion engine.

In contrast to the drive with combustion engine, the hybrid drive lacks decades of experience. Therefore, simulation solutions for the analysis and optimization of the interaction of combustion engine, electric motor and transmission are essential.

Efforts to operate the combustion engine with bio- or e-fuels in order to improve the CO2 balance can stress components of the combustion engine differently, sometimes even more.

In addition, there are new acoustic conditions. In phases of purely electric drive, the transmission noise is no longer masked by the combustion engine and can become the dominant noise source.

Our software is the market leader in the structural dynamics simulation of powertrains with internal combustion engines.

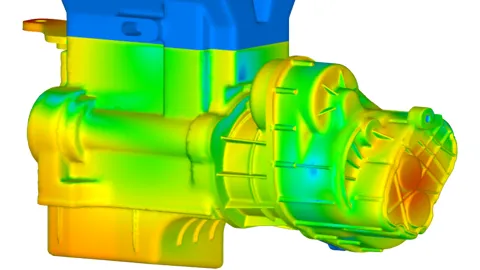

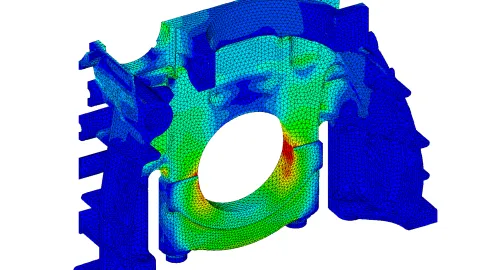

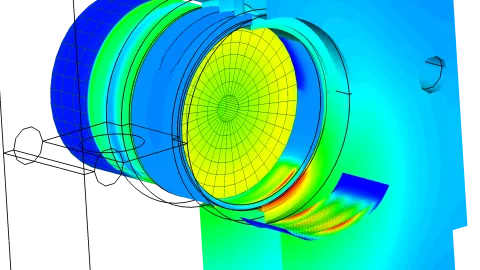

Decisive for the realistic and accurate results for strength and acoustic calculations are the detailed tribological models for the plain bearings and the piston group.

As an integrated solution of our simulation platform, many options are available to the user, which significantly simplify the calculation process and facilitate data exchange between different calculation disciplines. For example, results from the flow simulation can be easily adopted as boundary conditions for the structural dynamics simulation.

AVL's expertise is also integrated into our post-processing tools and workflows. Large amounts of data, such as those generated by acoustic calculations, can be automated and analyzed efficiently. Special tools for data analysis facilitate the assessment of the dynamic behavior of the oil film in plain bearings, the risk for excessive wear, the identification of relevant noise sources and much more.

AVL EXCITETM enables us to make reliable statements on the behavior of combustion engines from the early development phase to the start of production. By jointly considering the excitation from thermodynamics, the transmission of the structure and the high prediction quality, we can make reliable statements starting from the concept phase. In addition, the analysis of the vibration behavior of the test engines is supported with validated models in the prototype development. This allows us to target our development and ensure that the acoustic goal is achieved.

- Markus Dieterich, Development Engineer Acoustics, AUDI AG

AVL offers a multi-body simulation solution specific to the internal combustion engine, ranging from model setup support to powertrain-specific post-processing solutions. AVL engineering expertise included.

What sets our solution apart from all others on the market are the physical models we have developed and implemented in the multi-body dynamics simulation. These are so-called elastohydrodynamic contact models, which are very detailed. So detailed, that they represent plain bearings in the engine with all details, including the oil film.

The mobility revolution is in full swing. This is not just about developing new, more sustainable propulsion systems. Rather, the entire development process is in upheaval - with simulation taking the lead.

Right now, it's important to understand the challenge that each of us - OEMs and suppliers alike - face when it comes to pushing the boundaries of both our design process and our engineers. As the number of different systems grows, departments and team structures are changing. We understand that. At AVL, we go through these processes as well, because we are not just software developers. We are also engineers and therefore users. We implement our knowledge in intuitive workflows, generators, wizards, and evaluations in our software and projects.

We are your global partner in realizing the mobility of the future. A mobility characterized by its minimal impact on the environment. We offer you simulation solutions ranging from component to system analysis. As we are deeply integrated in the development process, our software solutions - tools and projects - enable you to master the challenges of virtualization.

75+

years of experience

in 26

countries worldwide

12,200

employees worldwide

68%

engineers and scientist