The inverter is a complex component, and its behavior and handling significantly influence the driving experience. To test and develop it independently from other components, a specialized test system is required. This system allows for testing the inverter early in the development phase – separate from the e-motor.

An optimized testing environment, such as the AVL Inverter TS™, leads to an efficient verification process and reduced testing time compared to testing the Unit Under Test (UUT) in a real prototype vehicle. This approach accelerates the development cycle while enhancing the reliability and performance of the final product.

The inverter is an intelligent mini-computer in electrified and electric vehicles. Together with battery and e-motor, they form the basis for the final driving experience. But, before all these components are tested together, every single one should be developed and validated on a dedicated test system. The frontloading of tests leads to shortened integration tests and therefore shorter time to market.

The inverter controls and monitors all driving conditions and the vehicle’s safety-critical functionalities. Power electronics, in combination with a high level of signal complexity, require an appropriate test methodology and the use of adequate testing equipment.

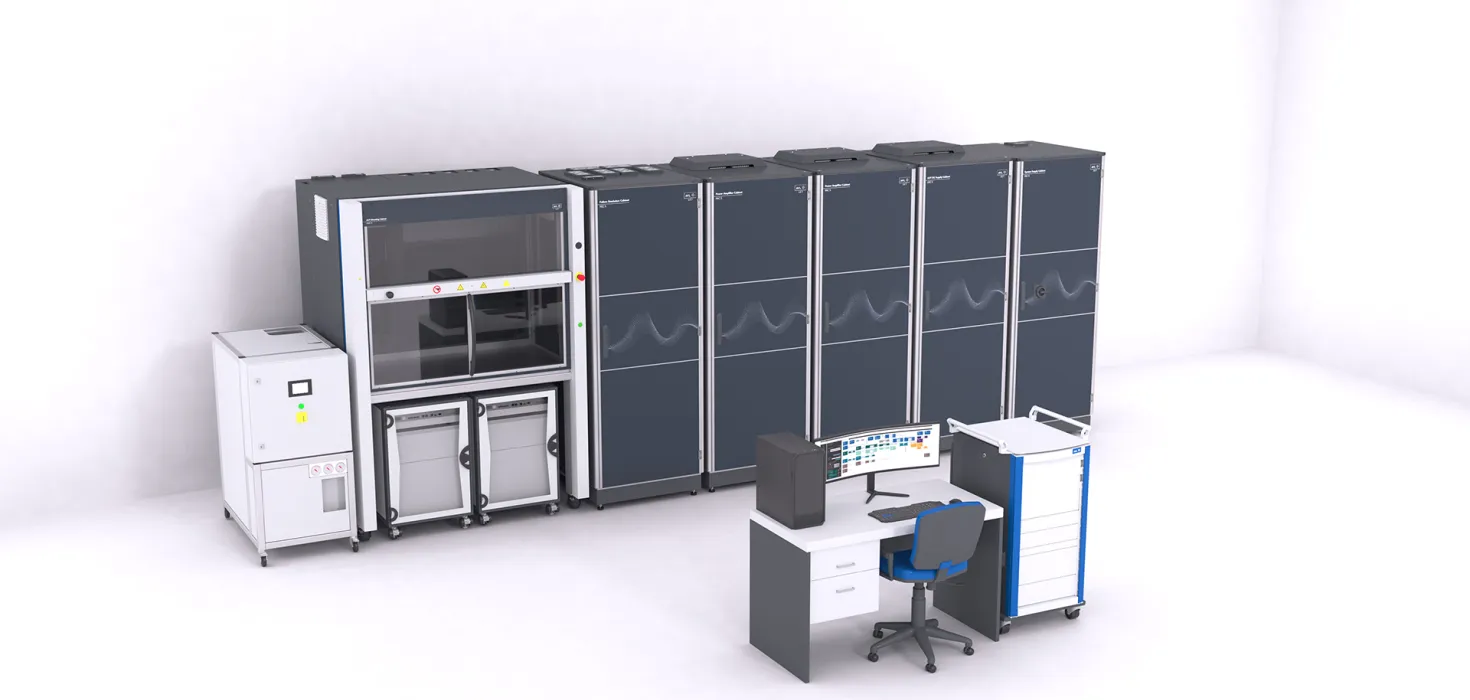

The AVL Inverter TS™ enables independent testing of the inverter while optimizing the integration with all other components in the electrified powertrain. The test system is based on e-motor emulation technology with real-time simulation. This leads to highly accurate results when testing the inverter with required battery voltage and e-motor current. For such a testing setup, exact copies of the e-motor and the battery are required.

Within the AVL Inverter TS™, the e-motor is replaced very accurately with the Power Amplifier Cabinet (PAC) and the Signal Processing Cabinet (SPC). The UUT DC Supply Cabinet (USC) represents a digital copy of the battery. As a result, an efficient and flexible test equipment for the testing of inverters is available, which – in contrast to an active load cabinet – emulates with highest accuracy the real physics of an e-motor directly at the terminals.

The emulated e-motor must replicate the behavior of a real e-motor with high accuracy. Our software tools are designed to optimize the use of test systems across their entire performance range and make our expertise accessible to customers at scale. These tools enable quick and correct machine model configuration without requiring deep expert knowledge. Additionally, they seamlessly integrate with existing systems, boosting overall efficiency and allowing for the effortless and precise management of even complex testing scenarios.

It is important to us to provide our customers not just with individual parts, but with a state-of-the-art, complete test system that is based on years of application know-how and thus enables our customers to use a highly efficient test methodology.”

– Dr. Tobias Schelter, Managing Director, AVL SET GmbH

We provide reliable and reproducible test results globally, with comprehensive test methodology and state-of-the-art products. Our solutions offer flexible, accurate, and fast mapping of all common motor concepts, and include emulating fault situations and inverter behavior testing.

This ensures thorough validation and optimization of your systems under development. Additionally, our global presence guarantees consistent support and expertise wherever you are. Learn more about our global presence and service network below.

AVL E-Mobility Testing Solutions – Brochure

Tested and Trusted.

AVL Inverter Testing Solutions – Brochure

Full test coverage for drive inverters makes the difference in power electronics testing.

AVL Inverter TS™ – Solution Sheet

How to enable the validation of the inverter and to prepare its integration into the electrified powertrain.

AVL’s automation platform PUMA 2™ represents the brains behind many different testbed applications. Our leading automation system is easily extendable to suit modern testing methods.

AVL PUMA 2™ Inverter features an outstanding intuitive user interface displaying all important values immediately. You can easily integrate the automation software into existing AVL test fields, allowing data to be shared across different testbed types and configurations. Our complete integrated solution covers all inverter testing requirements that arise from automation, limit monitoring and measurement, leading to the most efficient inverter testbed operation.

The AVL X-ion™ e-Power power analyzer is a modular data acquisition platform that is optimized for electric and hybrid applications.

AVL has a wide portfolio consisting of dedicated e-motor test systems, software, tools, and processes to test and validate these modern e-drive systems in shortest time and with highest quality standards.

AVL PUMA 2™ Inverter is a comprehensive automation system for inverter testing, offering everything you need in one place

The AVL Customer Services organization consists of more than 700 service- and application engineers worldwide, operating from more than 50 locations. Our global footprint is your local benefit.

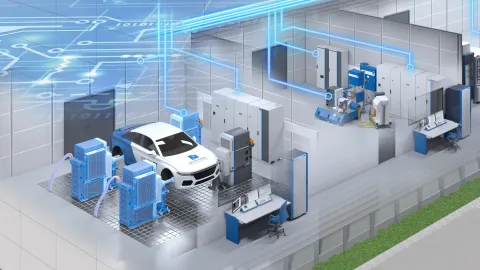

For every form of e-mobility, we offer in-depth expertise and comprehensive solutions for development, testing, and validation – from component to complete system, software, worldwide services and complete tech center solutions.

Transform your e-mobility analysis with AVL CONCERTO 6™, featuring fast data access, AI-driven technologies, advanced visualizations and calculations, and auto-generated reports for superior performance and precise insights.

The perfect hardware for AVL’s leading automation system

AVL CAMEO 5™ unlocks a new maturity level of calibration and validation in automotive software testing.

AVL’s comprehensive worldwide network of experts allows best customer vicinity, ensuring consistent and connecting testing fields globally. Wherever your R&D challenges take you, we are always close at hand, ready to provide the service you need.

> 70

years of experience

> 5,000

employees worldwide for testing solutions

> 30

countries covered by the global network

> 7,000

testbeds installed worldwide

> 80

turnkey projects

In this webinar a game-changing test environment is presented where the battery and e-motor are replaced with emulators, which are controlled from a powerful automation system.

- EN,

AVL List GmbH has appointed Matthias Dank as new board member and Executive Vice President (EVP). The top manager with international experience was previously at McLaren Applied, where he was Director of Motorsport.

- EN,

Latest projects from Northrop Grumman and Eviation presented at CES

- EN,

AVL RACETECH, the motorsport department of AVL, presents the prototype of an innovative H2 internal combustion engine. The power unit is a compact, hydrogen-powered 2-liter turbo engine, with intelligent water injection, which achieves a totally new performance level. The first racing engine that AVL RACETECH is developing and building in-house.

- EN,