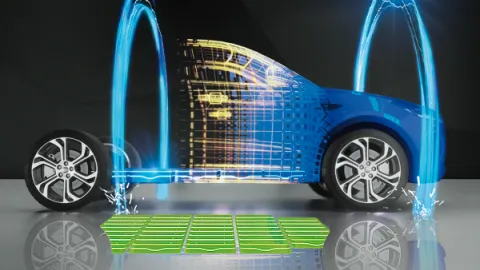

As electrified vehicles become more sophisticated, the complexity of VTMS sub-systems has increased. Unlike with combustion powertrains, VTMS must consider batteries, electric motors, inverters, and cabin HVAC systems.

This requires integrating multiple, interconnected thermal loops that operate simultaneously and minimize energy consumption. Innovations such as heat pumps, liquid cooling systems, and waste heat recovery add to this complexity by requiring precise coordination between hardware and intelligent software controls.

The challenge is compounded by the need for compact designs, dynamic adaptation to varying conditions, and compliance with stringent environmental standards. Simulation tools can play a crucial role in addressing this complexity by allowing engineers to model, optimize, and test VTMS configurations virtually, leading to more efficient and reliable designs.

Manage Complex Thermal Interactions

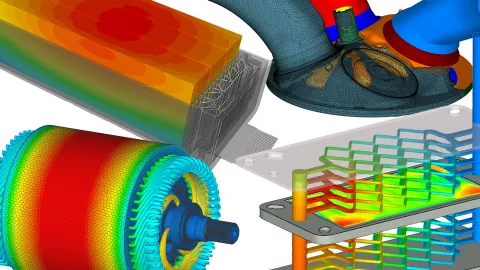

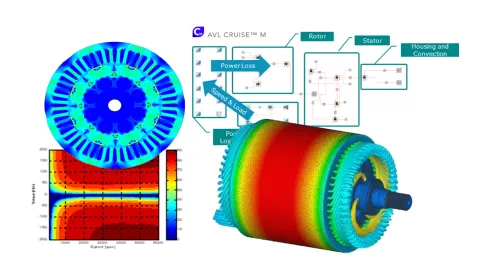

The integration of multiple heat sources like batteries and electric motors requires managing complex thermal interactions. Simulation allows you to model these interactions, ensuring efficient heat distribution and system reliability.

Optimize Energy Consumption

Balancing the energy demands of various thermal loops is crucial for efficiency. Simulation enables you to test different configurations and control strategies, optimizing energy consumption while maintaining performance.

Ensure Compact and Adaptive Designs

Designing compact systems that adapt to varying conditions is challenging. With simulation, you can explore various design scenarios and adapt your VTMS to meet space constraints and dynamic operational requirements.

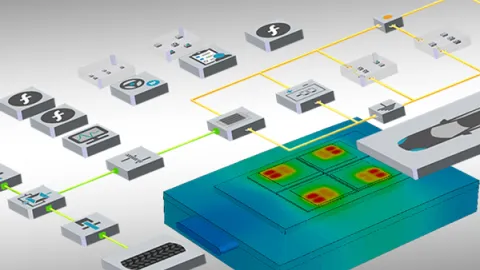

Our simulation solution seamlessly combines thermal, mechanical, and electrical systems in a consistent, user-friendly environment designed for non-software developers. With an intuitive workflow, users can quickly set up models using an integrated topology generator and parameterization wizards to guide them through the process.

From system layout and sizing to control strategy and derating calibration, the software covers a wide range of engineering tasks. It also supports HVAC system optimization, ensuring ideal passenger conditions by considering key factors such as sun exposure, humidity, cabin insulation, altitude, and more.

It covers applications like:

- Thermal management for any vehicle architecture, from components to full systems

- Cooling, heating, HVAC, and lubrication system assessment

- Thermal system topology design and layout

- Component sizing and pressure drop evaluation

- Reduction of thermal losses and optimization of thermal networks

- Detection of critical thermal conditions

- Development of control strategies for thermal management

Reduce Thermal Losses

Identify and minimize heat losses in HVAC systems through material optimization and advanced insulation strategies, leading to improved energy efficiency.

Optimize Interconnected Thermal Networks

Analyze and optimize interactions between thermal systems to ensure efficient, balanced operation across powertrain, battery, and cabin climate control, enhancing overall vehicle performance.

Detect Critical Thermal Conditions

Predict and mitigate risks of overheating or undercooling early in the design process, preventing failures and ensuring reliable, comfortable vehicle performance.

Support Control Function Strategy

Develop and refine sophisticated control algorithms for efficient heating, cooling, and ventilation, adapting to dynamic driving conditions and improving system responsiveness.

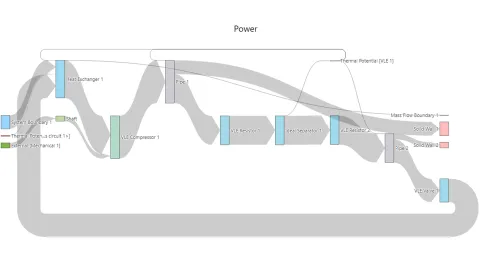

Sankey Diagrams

Visualize power and energy distribution across your system with Sankey diagrams, helping to identify potential bottlenecks and optimize component scaling.

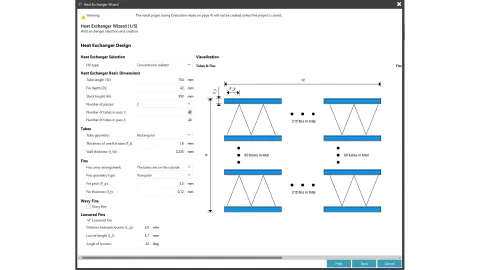

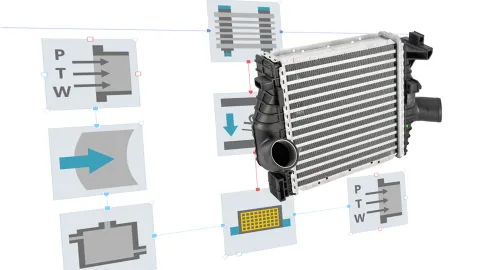

Heat Exchanger Wizard

Easily design and optimize heat exchangers with our Heat Exchanger Wizard, which guides you through the dimensioning and configuration process, ensuring efficient thermal management.

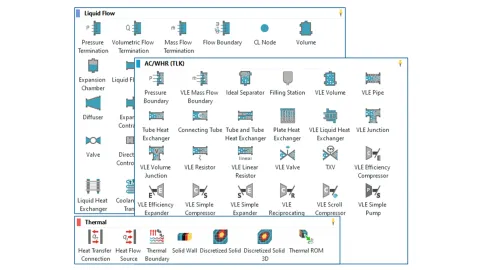

Comprehensive Component Library

Access a wide range of pre-defined components for rapid model assembly, allowing for detailed analysis and optimization of thermal networks.

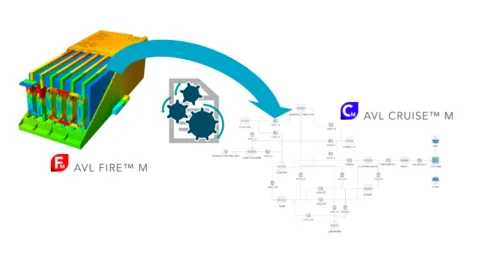

Thermal Network Generator

Convert complex 3D CFD models into efficient 1D thermal network models, significantly reducing simulation time while maintaining accuracy.

Do you have questions or want to work with us?

Our experts are happy to help.