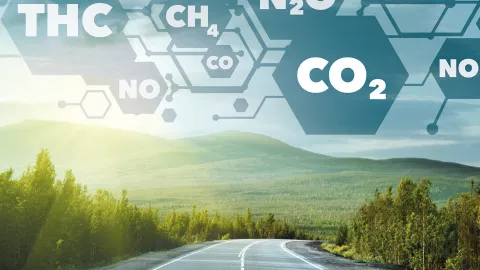

Ever more stringent emission legislations with new and longer test cycles, along with the growing complexity of engine and powertrain testbeds all place high demands on exhaust emission testing technology:

- Multi-step exhaust aftertreatment system analysis requires a higher number of exhaust gas sampling points. Yet the sampling volume must have no effect at all on the engine or the exhaust aftertreatment system.

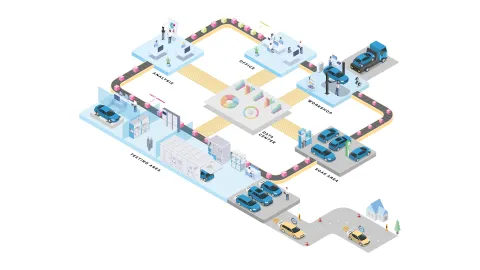

- The measuring systems are part of complex testbeds with numerous test parameters, so they must be capable of effortless integration into the testbed automation system.

- The systems’ efficiency depends on highly stable operation, reliable measuring results and user-friendly servicing concepts.

- For testbed operation to be cost-efficient, maintenance requirements must be minimal and the number of costly and time-consuming test runs for each measuring task must be as low as possible.

- Due to the large number of necessary measuring systems, system operation represents a significant cost factor.

The AVL AMA SL™ is a high-end measurement device that provides you with reliable and accurate exhaust gas insights:

- Wide dynamic measurement range for up to eight exhaust gas components in one stream

- Additional calculation of the exhaust gas recirculation rate (EGR) by measuring CO2 from a second sample point

- Simultaneous measurements with one system at two sampling points, e.g. in order to assess the catalyst efficiency

- Parallel exhaust measurements at multiple sampling points for a wide range of engine sizes thanks to a 75 % reduction in exhaust sample volume, and a 90 % reduction in EGR sample volume.

| Technical Data | |||||||||||||

|

|||||||||||||

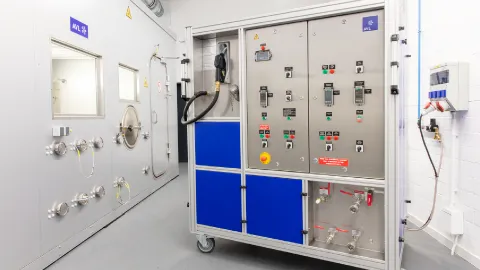

The AVL AMA SL™ completely redefines the status quo of exhaust emission testing. The main advantages of the revolutionary design are:

Slim

Its slim footprint with a depth of only 30 cm opens up totally new possibilities in test center design.

Robust

Its unique, robust, and service-friendly design allows for a maximum testbed availability by e.g. 50 % reduction in service time.

Accurate

It is designed to operate with very small sample flows without an impact on the unit under test.

Efficient

Lower than with any other measuring system, it consumes 40 % less energy and halves maintenance requirements.

Green

40% lower CO2 footprint, 30% less wear parts, 10% reduced gas consumption compared to conventional systems

Significantly reduced noise emissions, power consumption and heat dissipation

The AVL AMA SL™ is the discreet star of the testbed and excels due to its sustainability. It requires less energy, gives off less heat and is pleasantly quiet. It can therefore also be installed in the operator room.

Risk-free internal access due to 24/48 VDC operation

Owing to extra-low voltage supply, the system is safely accessible during operation too. This allows the staff to service an analyzer, for example, while the other analyzers continue to complete their test order. Additionally, there are no country-specific designs for the system components.

Easy handling

The measuring system is automatically registered in the testbed network and integrated with just a few mouse-clicks. The AVL AMA SL™ control software is based on the powerful iGEM software platform, which works perfectly together with the AVL PUMA Open 2™ testbed automation system.

The AVL AMA SL™ has been proven to be reliable and stable and we clearly see its advantages.

– Dr. Michael Röbel - Head of Process Technology and R&D Investments, DEUTZ AG