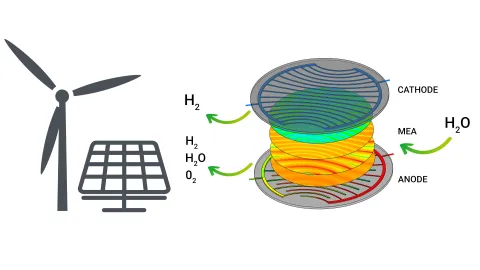

Electrolysis technology is now at a high level of maturity for alkaline or PEM (polymer electrolyte membrane) and is thus ready for industrialzation. But also new technologies like AEM (Anion Exchange Membrane) or SOEC (Solid Oxide Electrolyzer Cell) are in the making.

To satisfy the green hydrogen demand, the industry requires validated and robust solutions for which state of the art development methodologies and holistic testing tools are in high demand.

AVL is the innovation partner supporting every step in the industrialization from the first concept to in-field services with methodologies, know-how and tools.

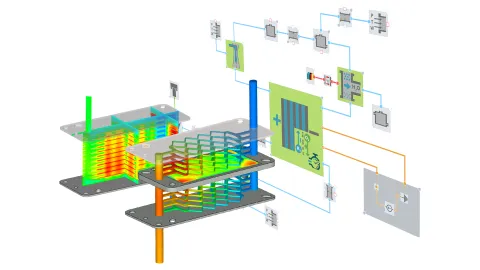

Cell & Stack Testing Solutions

Greenlight is the world's leading supplier of test stations for research on PEM and alkaline electrolyzer cell and stacks. The AVL partner company has been manufacturing test equipment for electrolyzers since 1996 and can provide references from major companies and research institutes worldwide.

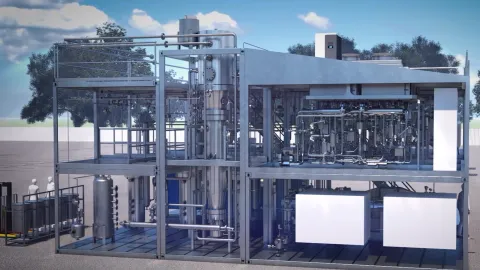

System Testing Solutions

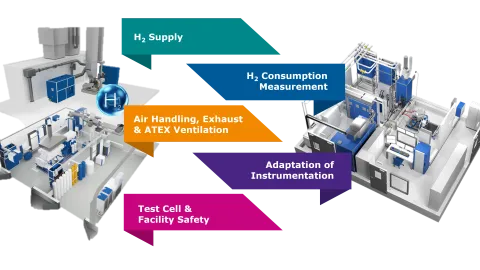

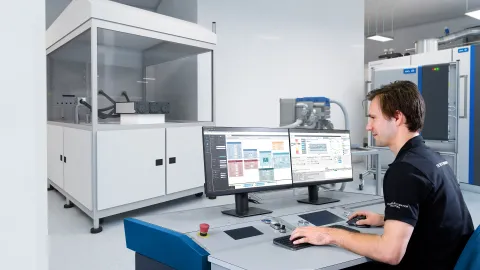

The system integration and in-field operation of electrolysis systems are major challenges for the industry. AVL's electrolysis system testing solution is a tailored development platform to satisfy the testing needs of complete electrolysis systems in the megawatt range.

AVL has a unique advantage due to our global engineering centers and diverse customer base. This provides us with a comprehensive understanding of future market developments. Combined with the fact that we build and operate our own tech centers makes us perfectly suited to offer this expertise to our customers through consulting projects.

“Our testing solutions are designed to accelerate the transition of hydrogen production technologies from lower technology readiness levels to fully industrialized solutions.”

- Dr. Daniel Ritzberger, System Line Manager AVL List GmbH

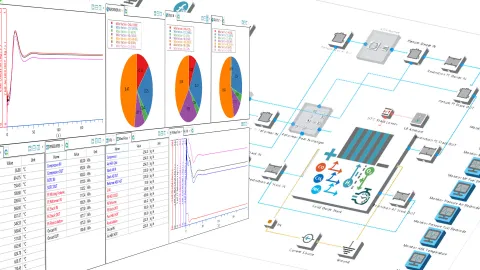

AVL's automation, simulation and data analysis solutions augment electrolysis testing needs and allow for the seamless integration and analysis of model based development methodologies and data analysis into the development and testing workflow

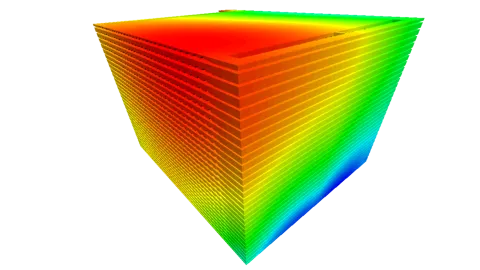

Finding errors at an early stage, observing degradation effects, and evaluating the state of health are crucial tasks for a wide range of applications in all stages of development – from R&D to end-of-line tests.

Specific development needs require purpose built equipment and AVL is here to provide the solution right for the job. From integrated testing platforms down to individual sensors and measurement products.

Power analysis, electrochemical impedance spectroscopy, gas analytics, fluid conditioning and measurement equipment, high speed data aquisition tools are just some examples of the broad portfolio of AVL.