While exhaust emissions (ICE) are decreasing, a new focus is being placed on non-exhaust emissions caused by brakes, tires and road surface wear.

Shaping the Future

As part of the Particle Measurement Program (PMP), the United Nations Economic Commission for Europe (UNECE) in collaboration with all OEMs and countries has devised the Global Technical Regulation 24 (GTR-24). This defines the measurement method, measured quantities, and processes. The Euro 7 regulation, which comes into force for light-duty vehicles at the end of 2026 and then for heavy-duty vehicles two years later, sets corresponding limits.

Brake Attributes Balancing

Brake developments have primarily focused on performance and feel as well as thermal behavior, durability and noise, vibration, harshness (NVH) over the past 30 years. With the introduction of the Euro 7 regulation, entirely new tribology systems are now in the spotlight – a reboot for everyone involved in the development process. Every change to the brake system requires adjustments to performance, durability, NVH, and the brake pedal feel.

We help you overcome these challenges by evaluating functions, optimizing coatings and surface materials, developing recuperation and blending strategies, integrating filters, and bringing these innovations to series production.

Brake Functions Development

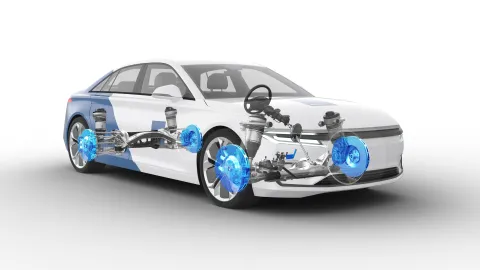

Increasing propulsion system electrification and ADAS features and functions require new brake system solutions. Therefore, AVL offers brake system-design, -functions, -functional safety concepts and -components development such as Brake-by-Wire, electromechanical brakes, overlapping recuperation and friction brake including corresponding ABS as well as wheel slip, TCS, ESC control.

At AVL, all divisions collaborate closely to offer you comprehensive support. Our in-depth systems understanding enables us to guide you all the way from Testing-as-a-Service to brake attribute engineering.

Our first step in brake emissions engineering is usually the evaluation of your brake emissions. We can also measure the vehicle-specific coefficients for considering recuperation (iFBSC).

In addition, we extensively review braking properties – including emissions, thermal behavior, NVH, performance, durability, and pedal feel. This is how we ensure that all components in the overall system harmonize optimally and comply with the current statutory requirements.

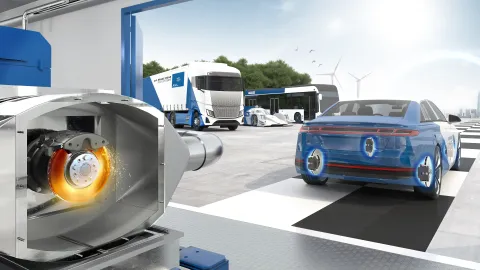

As the modern hard-metal-coatings on brake discs can cause noise in the system, we address this challenge when carrying out your NVH analyses on the test bench of our partnering companies.

If required, we can also take care of the related ABS and ESC calibration. In cooperation with a technical service provider, we also offer the homologation of brake components and retrofit parts on the test bench as well as the entire brake system in the vehicle.

With AVL, you benefit from seamless methodology that unites innovation and efficiency. We use state-of-the-art requirements engineering and the latest virtual development methods to provide optimum support for your systems engineering.

We Test Emissions For You

We currently run six testbeds for measuring emissions – five in Graz and one in Japan – with potential for expansion. Here we investigate all possibilities for reducing emissions. The deep insight we gain from the measurements enables us to make precise interpretations.

We Build Demo Vehicles For You

We build tailored demo vehicles that make new technologies tangible. Our service goes way beyond brakes – we also integrate the latest developments in steering. A recent example being the realization of our demo with a dry brake system (electromechanical brakes) including our specially developed control software for ABS, ASR, and ESP.

We Align With Your Requirements

In addition to the complete system, consisting of hardware and software, we are also happy to provide a white box solution. For example, we offer this for brake-by-wire systems that you can either work with us to refine, or that you can adapt yourselves.

Component/Systems Engineering

Based on Euro 7 emission limits, we take care of brake- and propulson system development for you. There we focus on a holistic optimization of electric propulsion and brake system operation considering effects onto:

- Energy management

- Range

- Driving attributes

- Brake emissions

- Thermal aspects

Identification and Optimization

During baseline measurement we identify potential and optimize this to reduce, eliminate, or prevent emissions.

Perfect Interaction of All Attributes

We carefully consider all properties that influence each other.

Integration

We integrate new emission reduction technologies such as active/passive filter systems, multiple-disc brakes, or electromechanical brakes into the vehicle.

Related Topics

We are constantly working on new solutions. The following might be interesting for you: