Download: AVL White Paper – Using CFD for Quenching Optimization

Heat treatment enhances the physical properties of many automotive or aircraft components, but quenching can introduce distortion and stress. Immersion or direct quenching in oil or water is common in the production of cast or otherwise-produced metal parts, but the aggressive boiling of liquids is chaotic. Besides, the physical properties of the components can vary significantly with seemingly small differences in the process, such as the position in the racking, agitation of the quench pool, orientation of the part, etc.

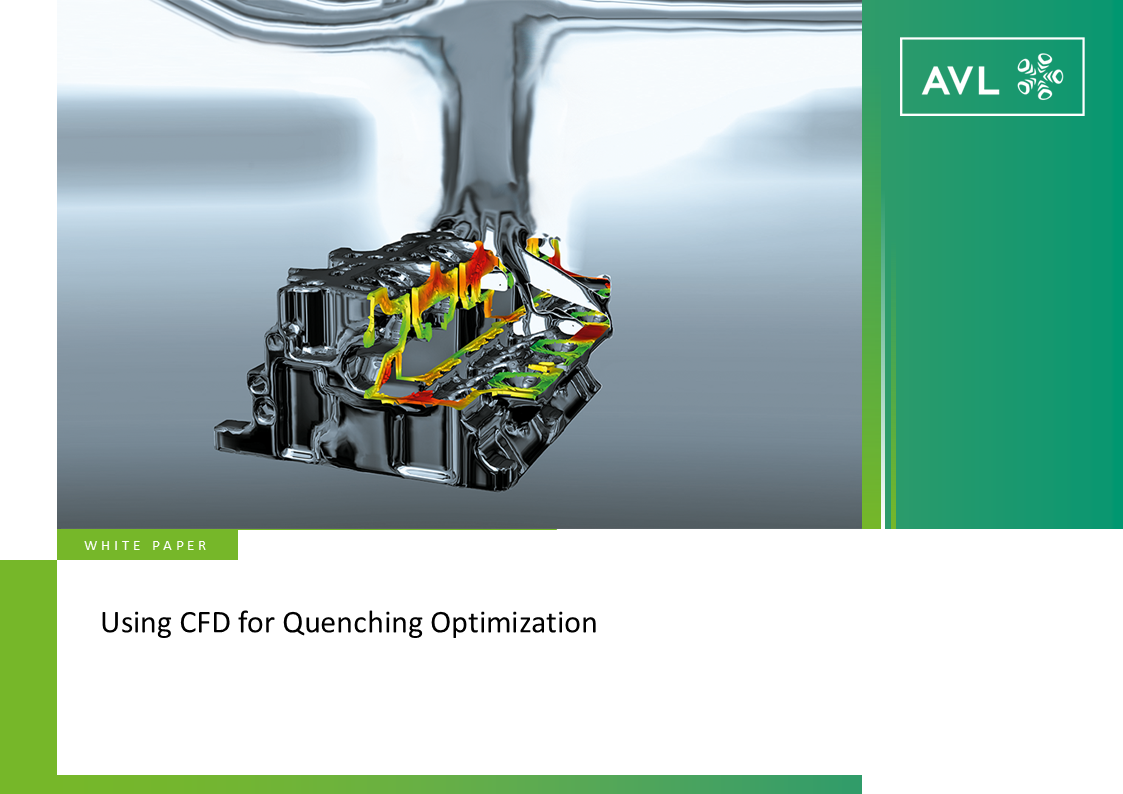

Simulation enables engineers to visualize and adjust the precise location and rate of heat transfer during the quenching process, which will increase quality and productivity, and reduce waste.

This White Paper highlights the role of virtual prototyping in this process and explores how automotive, aerospace or other industries will benefit from CFD simulation.