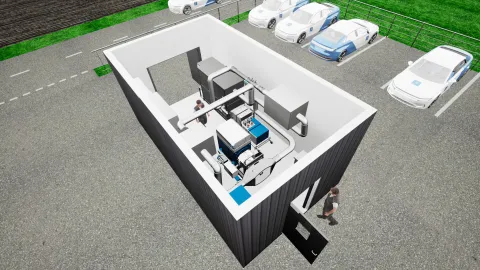

Our test systems are available in tech center modules that are quickly up and running. The solution consists of a fully integrated test system in a containerized format. The module can operate independently to a high degree, only requiring a flat surface to be located on and the necessary external power and media connections.

Through standardization, supply chain management and preemptive engineering efforts, we have significantly reduced the time from order to start of operation at the customer site. This provides our customers with optimal flexibility to respond to changing needs and limits their capital commitment.

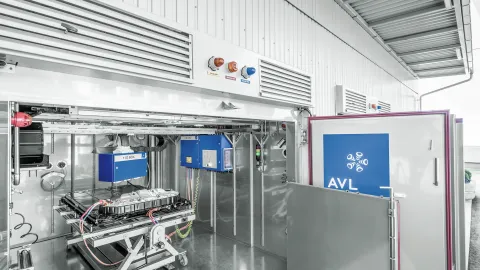

AVL Battery Pack TS™

The battery testing module is the cost effective and quickly available solution for climatic testing of packs and modules. A remarkable short delivery time is achieved by the optimization of standard solution using proven components. → Learn more

AVL E-Axle TS™

The e-axle testing module is the complete solution to develop, test, verify and validate an e-axle, with a single or dual motor setup. The delivery time has been reduced to a minimum while achieving a very attractive price. → Learn more

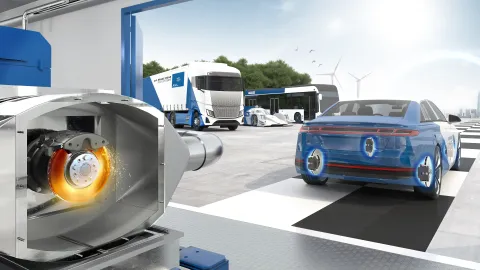

AVL Brake Emission TS™

The brake emission module addresses the extensive testing needs triggered by the upcoming brake wear emission legislation. It is offering capabilities beyond the GTR requirements, ready for testing in less than a year.

→ Learn more

With our Tech Center Modules, we offer cost effective solutions that are up and running in a very short time. It is particularly valuable for customers who needs to act fast on changings needs and where the requirements on the installation location must be kept to a minimum.”

– Stefan Sohar, Solution Engineer, AVL List GmbH

AVL Tech Center Solutions – Brochure

Gain a quick overview of our portfolio

AVL Tech Center Solutions – Booklet

From requirements to reality.

AVL E-Mobility Testing Solutions – Brochure

Tested and Trusted.

Tech Center Module – AVL Battery Pack TS™ – Solution Sheet

The fast track to battery testing excellence.

Tech Center Module – AVL Brake Emission TS™ – Solution Sheet

The fast Lane to ramp up brake emission testing.

Tech Center Module – AVL E-Axle TS™ – Solution Sheet

The fast lane to ramp up e-axle testing.