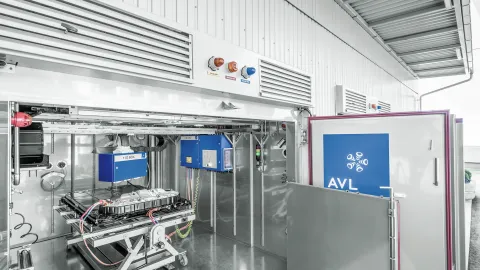

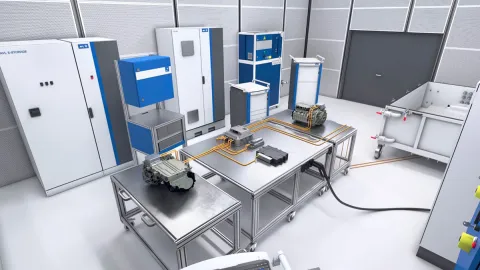

The AVL Battery Module/Pack TS™ is a fully integrated test system designed for reliable and safe battery testing at module and pack level. It combines advanced technology, robust safety features, and seamless system integration to meet the demands of modern battery development.

Key Features:

-

AVL E-STORAGE SiC™: Battery tester for efficient testing

-

AVL PUMA 2™ Battery: Automation system for smooth test execution

-

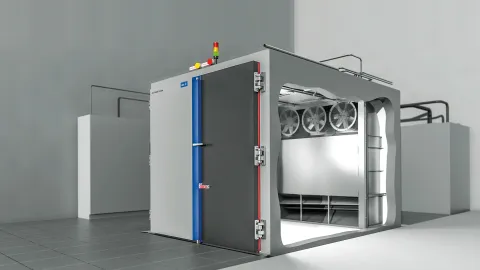

Climatic Chamber : Simulates temperature and humidity for real-world testing conditions

-

Advanced Safety Architecture: Includes overpressure protection with enforced chamber, burst disk, and overpressure flap

-

AVL Safety Concept: Fire protection planning and risk mitigation

-

Gas Detection and ATEX Extraction

-

Fire Detection and Suppression: Rapid response systems for maximum safety

-

Pre-installed Media Supply : Network for electricity, air, and water

-

Facility Management Integration: Smooth integration via testbed safety PLC for centralized control

| Main Modules | Main Features |

|

AVL E-STORAGE Battery Tester |

Power range up to 2,200 kW / 4,000 A / 1,200 V |

| AVL Climatic Chamber | Temperature range from -40°C to 85°C |

| Measurement instrumentation | No switching time between charging and discharging |

| Fully implemented AVL Safety Concept | Interacting with the Battery Management System (BMS) |

| Pre-installed facility subsystems | Fast rise times combined with high accuracy |

| Defined interfaces to customer infrastructure | Full sinusoidal power feedback onto the main electrical grid |

Complete Battery Competences

Synergy between engineering, simulation, and testing thanks to complete battery competence in-house

Numerous Reference Projects

AVL is a competent partner for any kind of battery development and testing, with serval reference projects

Different Testing Applications Covered

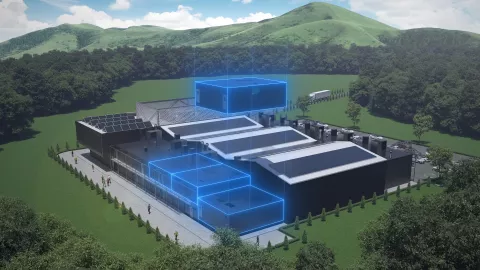

Optimized testing equipment for different battery testing applications up to turnkey solutions with containerized facilities

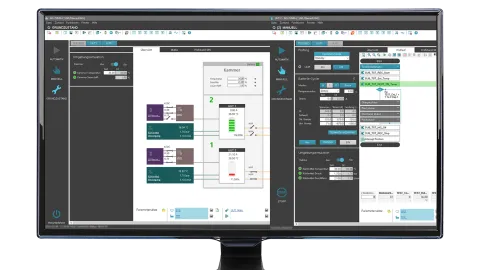

AVL Automation

AVL PUMA 2™ Battery is our consistent PUMA-based battery test automation solution to test all types of batteries. It lets you re-use your long-time PUMA 2 experience and share knowledge within your teams. You can also share data and parameters across different PUMA testbed types and configurations.

AVL Module and Pack Tester

AVL offers cyclers for all types of batteries, from cell to module and pack testers. The extended test range of our solutions cover UUTs > 800 V (AVL E-STORAGE SiC™) and an output current ranging from ±2 A to ± 1500 A (AVL Cell and Module Tester™).

AVL FEM 4™

The next generation of AVL data acquisition for electric, hybrid and combustion engines provides you with highest measurement accuracy – calibrated according to ISO 17025, high galvanic isolation up to 1,500 VDC for electrification modules and an extended temperature range – 40 ... +80 °C.

AVL Climatic Chamber

Battery packs, modules and cells, fuel cells, e-drives and e-axles must operate safely and reliably in any environment. With the AVL Climatic Chamber you can simulate extreme environmental conditions for these applications in a testing environment.

As a partner with a global presence and with knowledge of battery development, simulation, and production, AVL is a reliable, competent partner in the area of test systems for batteries.”

– Martin Schweiger, Senior System Line Manager, AVL List GmbH

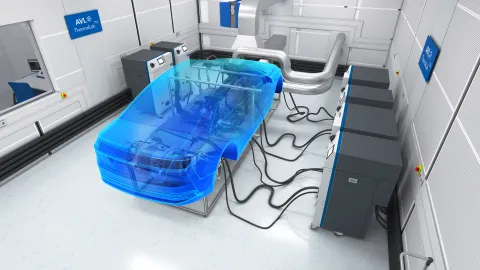

Battery testing on modern testbeds comes with significant safety risks. In the event of thermal runaway, conventional fire suppression methods often fail to stop the fire, potentially causing severe damage to the test environment.

The AVL Stingray™ Testbed sets new standards in battery safety. By targeting the fire source directly, the system efficiently cools the battery with water or liquid nitrogen. This significantly reduces both the amount of coolant required and the suppression time, while ensuring maximum protection for the test equipment. Fully integrated into the automation system, the process can be triggered manually or automatically for the highest level of safety.

AVL E-Mobility Testing Solutions – Brochure

From battery to full vehicle, from products, to test systems to whole test facilites – learn how we can support your testing needs.

AVL Battery Testing Solutions – Brochure

Learn more about our holistic battery testing portfolio and solutions.

AVL Battery Module/Pack TS™ – Solution Sheet

Exploring the limits with maximum safety.

Tech Center Module – AVL Battery Pack TS™ – Solution Sheet

The fast track to battery testing excellence.

Battery Testing: Aviation – Solution Sheet

Boost your battery test process.

Success Story – “Battery Testing for LABCO”

How AVL supported LABCO BTC in entering the world of battery development.