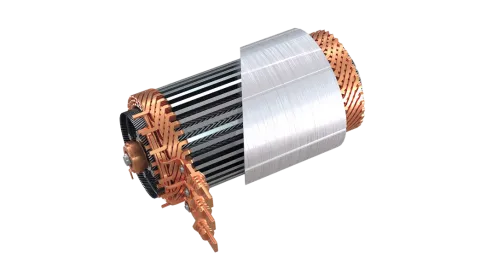

Electrification is firmly established in all mobility sectors and continues to grow. Electric motors, as an integral part of these systems, must undergo thorough testing for manufacturing defects before integration. This proactive approach significantly reduces the risk of production problems in later stages.

To remain competitive in the market, manufacturers need to adopt more efficient testing methods. These methods must handle increasing production volumes while ensuring faster results, lower costs, and reduced overall energy consumption.

Manage High Production Volume

Short cycle times, with a small number of reliable test beds.

Ensure Product Quality

Increased reproducibility of test results and ensure product quality.

Reduction of Cost

A solution with minimal investment, operation and maintenance costs is required.

Increasing Number of Variants

Fast and cost-effective test system adaptation for continuously increasing e-motor variants.

Leveraging our extensive expertise in R&D and production testing, we have developed a highly reliable and robust test system that improves product quality assurance (OK/NOK) for electric motors. This innovative system streamlines test processes, significantly reducing test time and total cost of ownership.

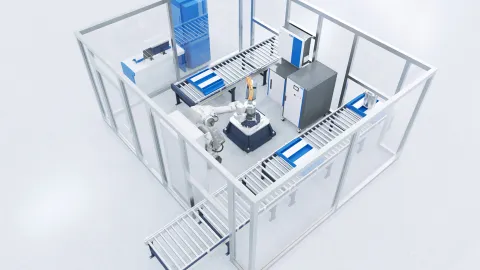

Unlike conventional e-motor end-of-line (EoL) testing solutions, our system eliminates the need for a dyno, e-motor cooling and traditional current, voltage and power measurements by measuring forces directly. The entire process - from mounting the e-motor to completing the test - takes less than a minute and delivers results at a fraction of the cost.

| Application | Designed to deal with high and very high production volume in all mobility industries. |

|

E-Motor Handling |

Fully automatic |

| Takt time | Down to 60 seconds |

| Measurement principle | Direct force measurement |

| Signal frequency | Up to 20 kHz |

| Derived measurement values |

Material and assembly defects |

| DC power source | For up to 1,200 V |

| Test cell footprint | About 8 m² |

Minimized Testing Time

A predefined test with less than 60 sec test time provides a complete data set for the holistic evaluation of the e-motor, and all that fully automated for 24/7 operation.

New Level of Quality Evaluation

Direct force measurement with fix installed sensors provides highly reproducible and reliable test results.

Reduced Risk and Cost

Ultra-compact, standardized design and absence of dynos and electric motor cooling significantly reduce investment, operating and maintenance costs compared to conventional test systems.

Flexible and Future Proof

Highly standardized and scalable solution enables fast and cost-effective test system adaptation to address increasingly growing number of e-motor variants.

Our patented test system uses piezoelectric crystal sensors to evaluate e-motor performance. Mounted on a dynamic force sensor plate, the e-motor undergoes quality checks by measuring forces during a load-free predefined test. This enables the assessment of critical parameters like cogging torque, torque ripple, imbalance, bearing forces, friction, NVH, and more. Additionally, the system provides real-time data analysis to ensure immediate feedback and precise adjustments.

The piezoelectric matrix makes e-motor phenomena visible in a way never seen before – beyond current, accelerometer and strain gauge technologies. In addition to torque and other conventional signals, even further e-motor phenomena can be derived from the measurement result, i.e. the system solution provides more data than required for a pure OK/NOK evaluation. This data can be used with other production data to determine optimization potential for the entire production line and the product design.

Quality will decline if it is not continuously improved, at least at the speed at which technology advances. Our innovative measurement method opens up new ways of fault detection and data evaluation for testing e-motors in all industries. AVL E-Motor TS™ EoL Unloaded significantly improves quality through fast and reliable testing.

– Ferdinand Mosbacher, Senior Solution Engineer, AVL List GmbH

AVL Production Testing Solutions – Brochure

Quality in Time.

AVL E-Mobility Testing Solutions – Brochure

From battery to full vehicle, from products, to test systems to whole test facilites – learn how we can support your testing needs.

AVL E-Motor TS™ EOL Unloaded – Solution Sheet

Quality by Forces.

Production Testing with Big Data – Whitepaper

How to Turn Production Testbed Data into Valuable Insights with AI