Fuel cells are complex systems. For their safe operation it is important to consider the interaction of a large number of operating parameters and external conditions, such as power demand, system temperature, humidity and temperature. Optimizing the operating strategy of a fuel cell stack is vital to avoid degradation and maximize durability. In addition, simulation plays a critical role in the fuel cell development process, from concept, design and throughout the testing and validation phases and beyond. By embracing virtualization, engineers can frontload development tasks and reduce the number of fuel cell prototypes needed to optimize the systems within a safe, highly reproducible and cost-effective environment.

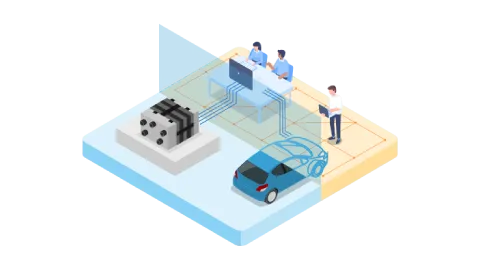

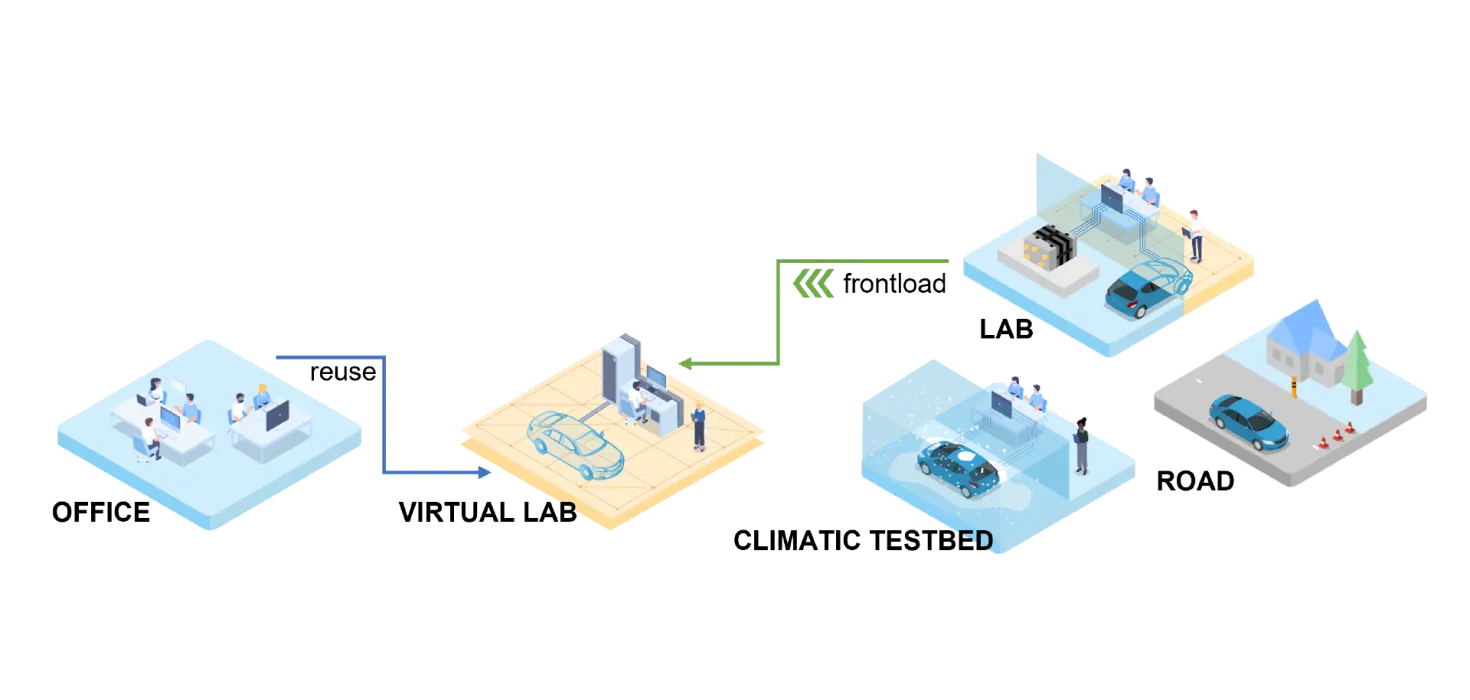

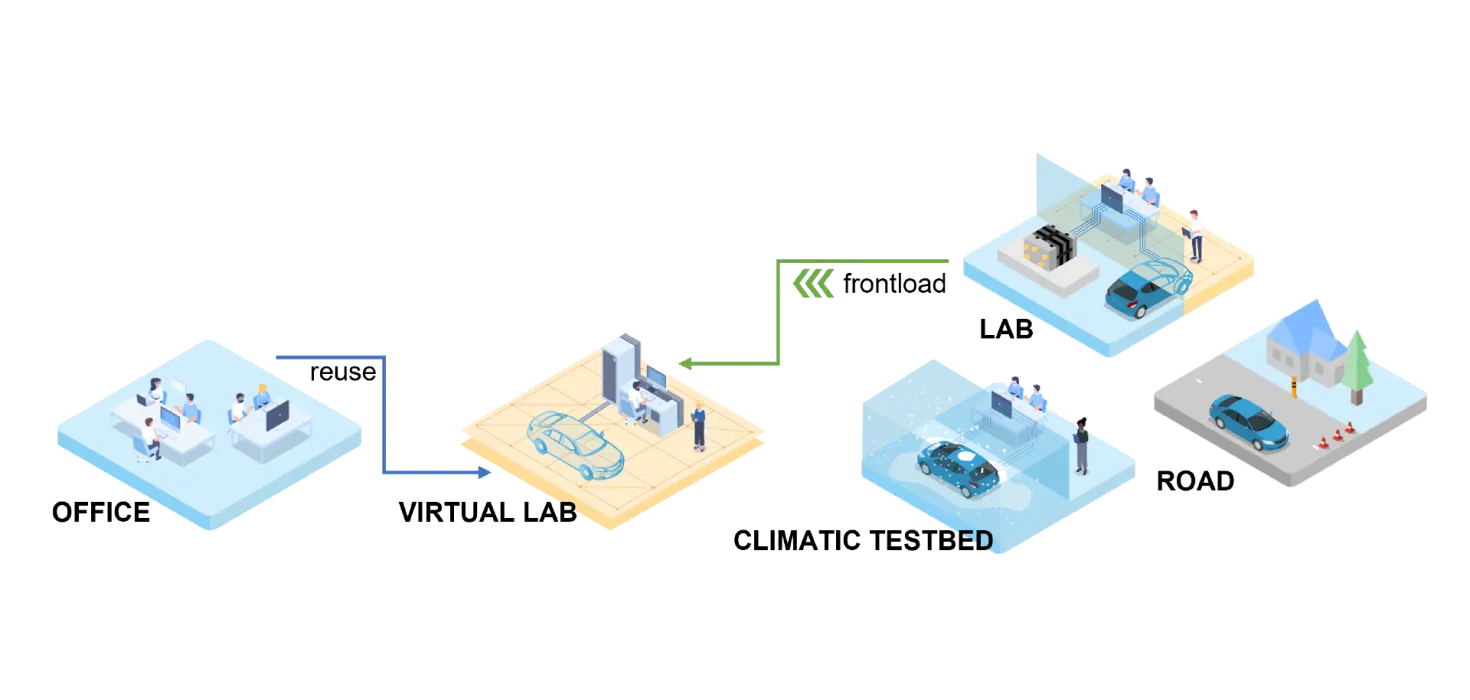

It all starts with high-performance models in the office environment to perform an initial optimization of the operating strategy. To enable a more realistic operation of the fuel cell system, the integration of the vehicle simulation into the test execution is crucial. The easy integration of real-time and non-real-time simulation models allows to further improve the test capabilities. At a later stage, when real controls are already available, the use of a virtual calibration environment ensures a smooth transition to the final validation of the operating strategy on the real hardware.

End-to-end solution

Support the development of fuel cells from the concept stage right up to SOP.

High model quality

Ensuring high model quality at every development phase, until real time implementation for calibration purposes.

Reduction of prototype costs

The virtual approach helps to get to a final product faster, at lower cost and higher quality.

Optimizations of the Operating Strategy

Right at the start of the development process, you can create performance models in the office environment, to conduct initial optimizations of the operating strategy. With high-fidelity models and optimization tools you can rely on a high level of automation to get the best results.

Virtual Calibration

When real controls become available, we support you in the use of a virtual calibration environment such as AVL Virtual Testbed™. At this stage, these tools act like a stepping-stone, enabling the smooth transition to the final validation of the operating strategy on real hardware.

Simulation of Fuel Cell Models

Access out-of-the-box simulation models, which require minimal parameterization to create highly sophisticated simulations. This allows you to simulate incredibly realistic fuel cell operation models and integrate them into hardware tests on the testbed.

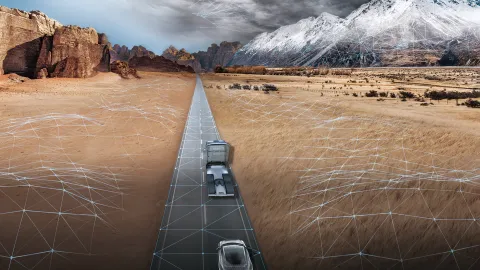

In fuel cell development processes, it is natural to rely on simulation results to support specification and design of products such as FCEVs. Embedding simulation and virtualization methods at testbeds frees up huge potential to reduce development and validation risks and improve its results quality at the same time.

– Tomas Dehne, Chief Engineer, Fuel Cell Testing Technology, AVL

Virtualization of Fuel Cell System Development

We are constantly working on new solutions. The following might be interesting for you:

Moving steadily into the future: Find out what’s brand new in the field of fuel cell operating strategy optimization and testing.