The e-mobility market is firmly established and expanding rapidly. As production volumes increase daily, testing must be done more efficiently and within shorter timeframes. The drive system of an electric vehicle (EV) consists of several components, including the e-axle or electric drive unit (EDU), which integrates the electric motor, transmission, and inverter.

While these individual components may have been tested separately, the entire e-axle must also undergo testing to detect potential assembly issues. Noise, vibration, and harshness (NVH) are particularly important factors in driver satisfaction, especially in the e-mobility sector.

High Production Volume

Handle high production volume with short takt times and maximum testbed up-time.

Ensure Product Quality

Ensure e-axle quality with minimum investment and operating costs to avoid harming recalls.

Secure Acoustic Performance

Detect acoustic abnormalities reliably before integration into the vehicle.

The electrified powertrain and testing requirements are driving up both complexity and costs. To overcome these challenges, new solutions are needed to reduce costs and accelerate time-to-market while maintaining high quality. With extensive internal AVL E-Axle development expertise and decades of experience in production testing, we have designed AVL E-Axle test systems based on simplicity and robustness.

AVL offers customized test system solutions for End of Line (EoL), Quality Assurance (QA), and Conformity of Production (CoP) testing, meeting the demands of modern e-mobility.

- AVL E-Axle TS™ End of Line

- AVL E-Axle TS™ Quality Assurance

- AVL E-Axle TS™ Conformity of Production

We support our customers with customized testing processes and appropriate testing solutions, defined by following characteristics:

Wide Power Range

-

Solutions for passenger cars, light-, mid and heavy duty vehicles

-

Standard solutions for power ranges up to 440kW (per wheel)

-

Power ranges above 440kW (per wheel) on request

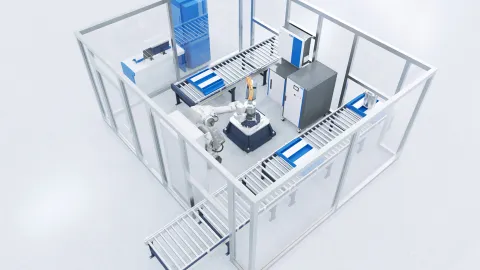

Flexible Layout

-

Small footprint

-

Brick & mortar or protective enclosure

-

Easy integration into existing production environment

Variable Testing Workflow

-

Preparation: Manually, up to fully automated

-

Handling: Trolley, conveyor, robot or AGV

-

Testing: Manual through match plate or automatically connected

New Way of Efficiency

Reliable 24/7 operation and highly automated workflow ensures large testing capacity addressing increasing industrialization demands.

Reduced Risk and Decrease in Cost

Ensure e-axle quality with minimum investment and operating costs and meet SOP schedules with on-time testbed delivery.

Experience it Before it is Built

Virtual Reality (VR) and Augmented Reality simplify and accelerate project planning, execution, training, and maintenance.

Ideal Partner for a Changing Industry

AVL continues development at the forefront of technology and can incorporate results into future-proofed testbeds with a long life.

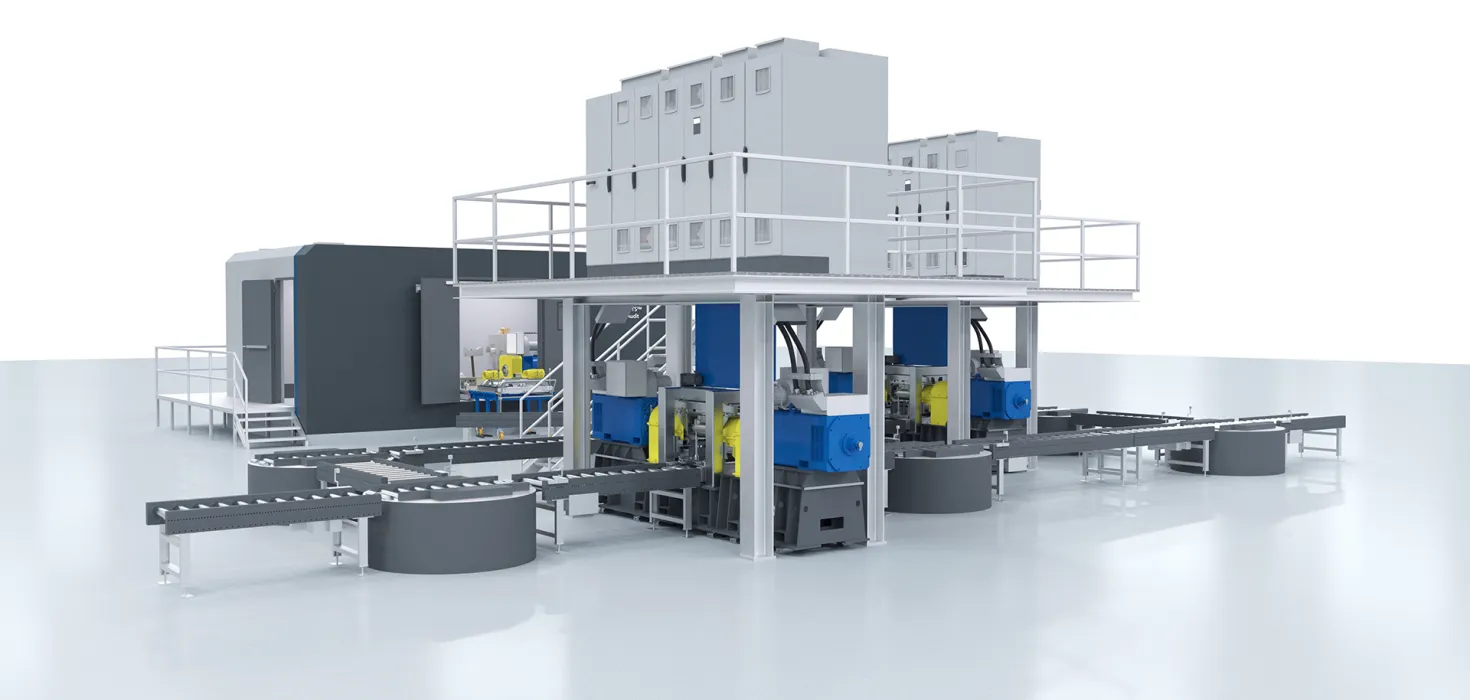

AVL E-Axle TS™ End of Line

The AVL E-Axle TS™ End of Line is a highly reliable and flexible test system designed to meet the demands of high production volumes. Its modular design allows for easy adaptation to increasing requirements, ensuring cost efficiency and scalability. With cycle times as low as 90 seconds, it enables fast and precise testing of e-axles for passenger cars to commercial vehicles. A broad mechanical and electrical power range ensures comprehensive testing capabilities. Backed by extensive expertise in e-powertrain development and a global service network, AVL is your trusted partner for precise and efficient end-of-line testing.

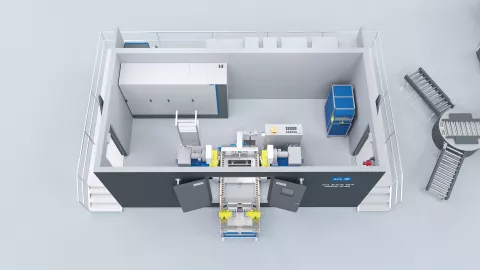

AVL E-Axle TS™ QA / CoP

The AVL E-Axle TS™ Quality Audit / Conformity of Production is a robust and highly reliable test system designed to meet the growing demands of industrialization and high production volumes in e-mobility. It ensures efficient testing while maintaining high quality and low costs. Supporting e-axles for passenger cars to heavy-duty vehicles, its scalable design and compact footprint allow for seamless integration into production environments. With decades of experience in production testing, AVL provides expert support throughout all project phases – from selecting the right system to securing SOP and ensuring long-term product quality.

At AVL, we see our production testing solutions as an important factor for both an effective production process and high product quality – a major pillar our customers can rely on.”

– Robert Nemeth, Department Manager, AVL List GmbH

AVL Production Testing Solutions – Brochure

Quality in Time.

AVL E-Axle Testing Solutions – Brochure

Validating Integrated E-Drive Units with Advanced E-Axle Test Systems.

AVL E-Mobility Testing Solutions – Brochure

From battery to full vehicle, from products, to test systems to whole test facilites – learn how we can support your testing needs.

AVL E-Axle TS™ EOL – Solution Sheet

Test Fast. Judge Confident.

AVL E-Axle TS™ QA / COP – Solution Sheet

Highest Flexibility. Complete Quality.

Production Testing with Big Data – Whitepaper

How to Turn Production Testbed Data into Valuable Insights with AI

Success Story – “Spinning E-Axles”

Quick and lean solution helping TEXA with e-axle industrialization.