Our Approach

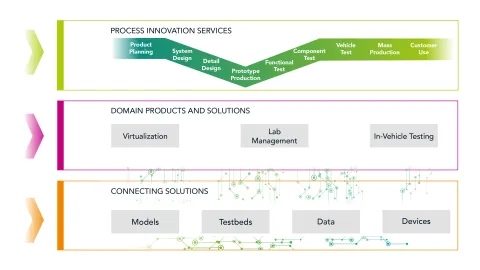

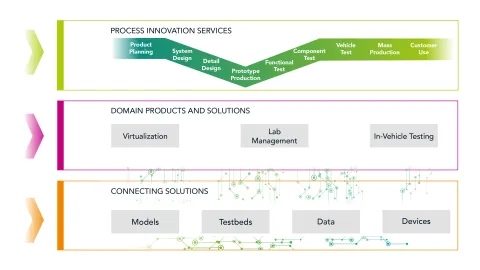

Achieve faster, more efficient and more agile development processes through the introduction of new methods and a stronger focus on software-centric development: From the optimization of the development process with Process Innovation Services to suitable products and solutions for Virtualization, Lab Management and In-Vehicle Testing. Additionally, we achieve a new era of interoperability with Connecting Solutions that integrate simulation models, testbeds, devices and data across processes, tools and manufacturers. Our offering can be tailored to your specific development ecosystem and processes to give you instant access to the full knowledge and capabilities within your organization.

Our Vision

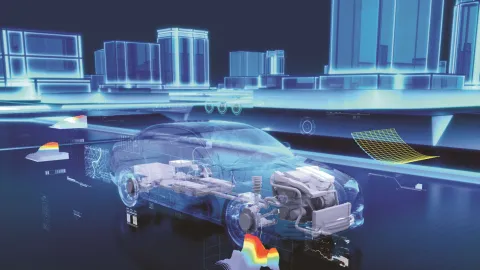

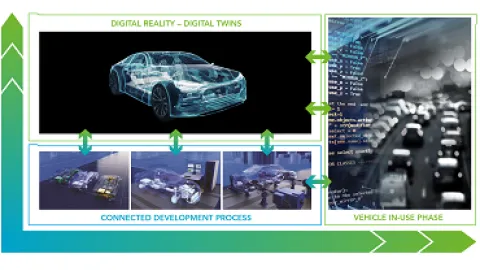

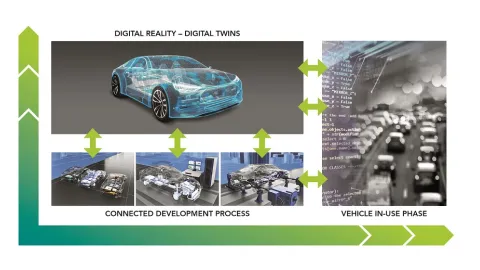

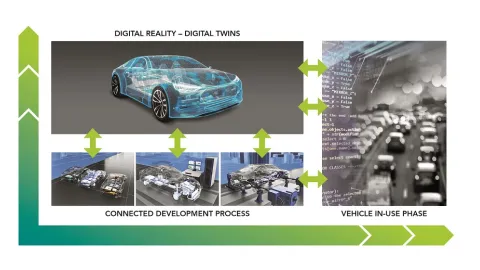

Developing a product is an iterative and fast-paced process, and although the vehicle development process contains an immense amount of knowledge, data and expertise, inefficiencies easily creep in. With the Integrated and Open Development Platform (IODP), you can connect the many aspects of your development process by merging the virtual and real worlds. Simulation models, test environments, devices, data and automation solutions work together to accelerate the process of developing an entire system or product. You benefit from the optimization of internal resources which allows you to develop entire vehicles more quickly, efficiently, effectively and at lower cost than otherwise possible.

Connected Development

In our FOCUS Collection, a special edition of our renowned customer magazine, we present you a compilation of articles written by our experts. We take you on a journey through our ecosystem portfolio, show you examples and provide you with helpful information on how you too can future-proof your development ecosystem.

Process Innovation Services focus on optimizing every step of the development process, from product planning, functional design and component testing to the vehicle in-use phase.

Our domain offering provides tools and solutions for specific applications, such as Virtualization, Lab Management and In-Vehicle Testing. They consist of proven solutions that are tailored to the specific development activities and engineering needs.

Connecting Solutions enable the optimal use, re-use and sharing of models and data from all activities, testbeds and devices throughout the development process - independent of tools and suppliers.

Process Innovation Services

Our consulting and implementation services help you develop a more competitive product portfolio by optimizing your development process and increasing the efficiency of your simulation and test factory. Scoping and expert workshops are complemented with proof-of-concepts (PoCs) and pilot projects. We show you how adaptations can bring measurable and significant improvements. Together with you, we create a roadmap and implement it in your processes so that your engineers can use the new capabilities as efficiently and effectively as possible.

Our dedicated toolchains

We develop CONNECTED Toolchains utilizing new methodologies that combine testing, simulation, data-management and technological know-how to increase the efficiency of a development process in terms of quality, time and cost.

Our consulting approach

In order to answer complex questions regarding the development process, a holistic approach must be taken. We support you with our many years of technological expertise, global network and extensive knowledge of future legislation and trends.

Leveraging experience, consulting customers

Improve development efficiency in terms of quality, time and cost

Endorse and support change

Virtualization Solutions

Traditional development methods are fast becoming outdated because of increasing system complexity. At AVL, we have come up with an answer to this challenge: we call it MOBEO. This approach is an end-to-end virtual solution with a proven methodology. It includes a comprehensive toolset, which has revolutionized the development workflow. The new MOBEO virtualization approach is the key to speeding up complex vehicle development and can help you shape the future of mobility.

Maximized development efficiency

MOBEO has transformed the physical development process to embrace simulation technologies. These can be applied to various use cases and tailored to your needs. It improves development efficiency by enabling system validation tests at an earlier stage in the development process before a physical prototype is available.

Reduced number of prototypes

MOBEO reduces the need for vehicle prototypes by 20%. It provides you with highly repeatable conditions in the physical testing environment. This means a wider spectrum of testing conditions. The results are higher test quality, better testbed utilization, and highly automated testing conditions.

Lab Management Solutions

Discover the software solution to increase the efficiency of your test facility. The modular solutions can be used for all types of test labs, from conventional automotive powertrain testbeds to battery test labs. With asset and process control, monitoring, data management and intelligence, and energy management for the entire facility, the solution offers scalable modules that increase your lab utilization, improve processes and communication, and lead to better reporting quality.

Extendable and customizable standard base configurations

Based on our know-how and insights, we have designed best-practice processes for three development domains. These standardized reference solutions are basic configurations that can be implemented out-of-the-box, adapted to individual requirements or even combined for labs with multiple testing focuses.

Easy integration with the modular approach

In combination, our software modules Asset & Process Control, Monitoring, Data Management, Analytics and Energy Management form the AVL Lab Management™ Software Solution. Thanks to the open concept, you can integrate single or multiple tools to your environment, independent of existing equipment.

In-Vehicle Testing Solutions

Increasing vehicle complexity has led to higher vehicle testing demands. There is a rising amount of time and money invested in prototype vehicles and in-vehicle testing. We can help you reduce the costs and time associated with your in-vehicle testing process. By centralizing testing data in a main hub – allowing you to trace and re-use it more efficiently – our in-vehicle testing solution removes the need for complex manual testing procedures.

One combined easy-to-use solution

Our In-Vehicle Testing Solution can be fully integrated into your current processes, allowing you to choose the tools you need to improve your testing procedures. Integrated planning, testing and data handling result in an automated testing process with strong data intelligence.

A digitalized, connected approach

Our solution offers a fully digitalized, connected approach to the entire in-vehicle testing process. Whether you want to save costs, time, reduce complexity, or increase quality and compliance, it offers all these benefits in an open package that can be integrated with minimal disruption.

Connecting Solutions

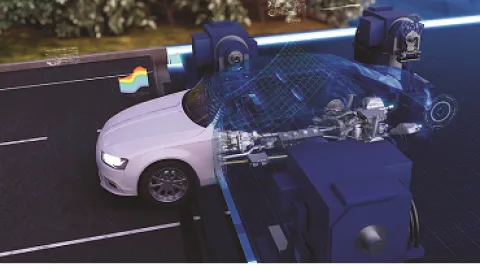

Simulation tools, databases and test equipment often come from different suppliers and have been created for different domains aggravating the interoperability problem. AVL’s Connecting Solutions to connect models, testbeds, data and even devices, support you throughout your development process. Continuous verification and validation (V&V) become a reality, allowing you to manage and trace all your V&V data and results, and providing your project with the continuous results and consistency it needs.

CONNECT elements

- Model.CONNECT™: Connect your simulation models to a virtual prototype

- Testbed.CONNECT™: Connect your simulation to the testbed

- Data.CONNECT™: Connect your existing data sinks and sources

- Device.CONNECT™: Connect your globally distributed devices with data centers to build your IoT

Key benefits

- Link virtual and real worlds.

- Enable continuous validation of your product.

- Provide prototypes for all development phases – virtual, mixed or real.

- Close the interoperability gap – models, testbeds, data and processes.

Combine simulation models into a consistent virtual prototype

Connect simulation to the testfield with our powerful execution platform

Harmonize, integrate, search, explore and automatically process data

Interlink globally distributed devices with highest data security

Lab Monitoring

From operating a single test cell to supervising an entire laboratory, engineering and operation teams are faced with the monumental task of managing a complex system of devices, people, and processes. Reduce the guesswork and risk for human error by leveraging a state-of-the-art monitoring solution: AVL PULSE™. The software solution aggregates existing operational data and adapts to your organizational structure and processes. With PULSE, these teams can collect data points for actionable insights for your laboratory.

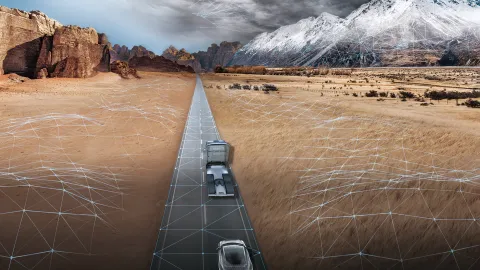

The vehicle development process is a source of incredible know-how, information and capabilities, but often inefficiencies occur because these assets are not connected. The goal of the IODP is the integration of all elements in the vehicle development process, blurring the lines between the virtual and the real worlds.

Simulation models, test environments, devices, data and automation solutions interlock and accelerate the development of the overall system. You profit from freed synergies and the whole range of know-how that exists in your organization.

- Prof. Helmut List, CEO, AVL

Our tools can be used independently, but they are also designed to interact smoothly when used together. Browse through our portfolio and find our well-known software like AVL CONCERTO™ for data intelligence, AVL CAMEO™ for validation and verfication, AVL CRETA™ for calibration management and many more.

Moving steadily into the future: Find out what’s brand new in the field of development speed and methodology.