With our deep knowledge of in-vehicle testing and proven track record in various automotive domains, we can help you reduce the costs and time associated with your in-vehicle testing process. By centralizing testing data in a main hub – allowing you to trace and re-use it more efficiently – our Remote Testing solution removes the need for complex manual testing procedures. Since software guides the drivers, our solution also removes the need for an expensive co-driver, which reduces your labor costs. Meta data is automatically generated and made instantly available, helping you minimize test variability and optimize your procedures on the fly.

Increasing vehicle complexity

Increasing vehicle complexity has led to higher vehicle testing demands.

Increasing prototype vehicles

There is a rising amount of time invested in prototype vehicles and in-vehicle testing.

Need for data security

We need the highest possible level of security and full control over data exchange.

Need for digitalization

Testing of vehicle prototypes on the street is still often based on manual procedures.

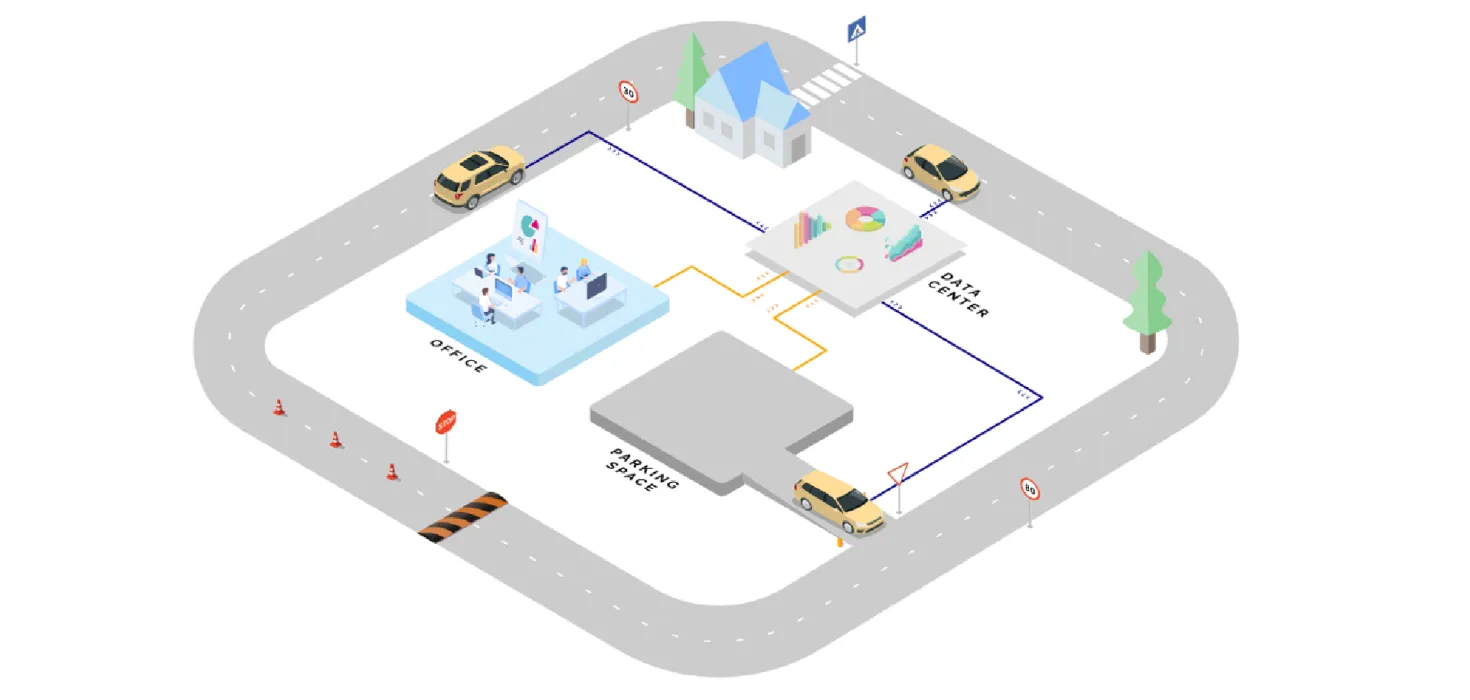

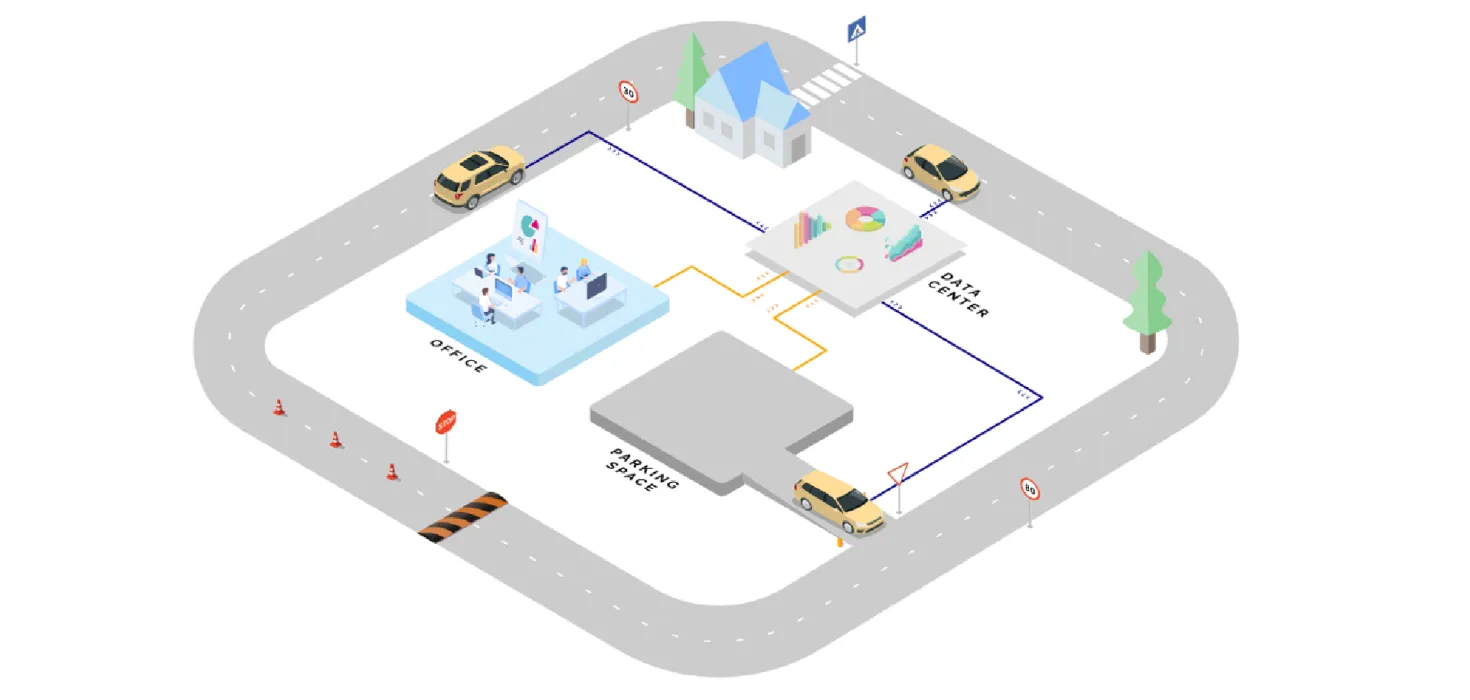

- Test preparation: The calibration engineer prepares the test environment, including dataset, software and configuration files for the application tools.

- Test package: The whole test environment package will be stored in the data center. The driver can download the test package for the specific vehicle.

- Execution: The driver will be guided through testing steps. After finalization an instant reporting will inform the driver if the test was executed accurately.

- Reporting: With the push of a button the data and reporting are uploaded to the target server.

- Data analysis: The calibration engineer in the office can do post processing and analysis.

No data silos

Data processing is not hindered by data silos, which reduces the associated effort.

50% less travelling

Local engineers can take over tasks, which reduces the need for calibration engineers to travel.

100% re-use

Once the test set-up is done, it can be re-used for any further in-vehicle tests.

Maneuver Assistance

The maneuver assistance features a customer-specific library allowing you to set up ‘playlists’ of maneuver sequences prior to beginning tests in the vehicle. As a virtual co-driver, it guides you through the test using audio-visual feedback, online evaluation and touch-screen functionality.

Driver Guidance

While driving, direct guidance on how to perform the test is provided visually and with audio output. In addition, the online evaluation gives direct feedback on whether the test was successful.

Automatic Data Storage

Measurement and calibration data is stored automatically on a server or project drive, on premise. You can always track all executed changes. By transferring all data to a desired server, you can easily share your tests with your colleagues for further analysis and re-use.

The nice thing of this solution is that it not only solves the initial problem of reducing travel, but also automatically brings improvements such as better data quality and traceability through automated processes.

– Marijn Hollander, Senior Group Product Manager, Smart Calibration and Virtual Testing, AVL

We are constantly working on new solutions. The following might be interesting for you:

Moving steadily into the future: Find out what’s brand new in the field of remote testing.