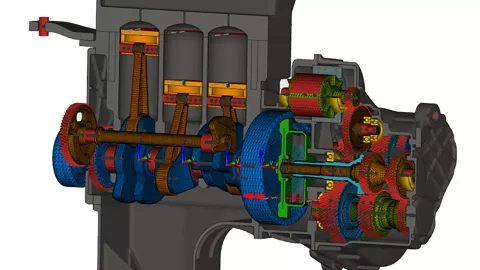

We have been involved in the development of internal combustion engines since 1948.

The beginnings of engine simulation date back to the 1980s. The simulation tools developed were initially used internally for project work on behalf of customers. In the early 1990s, we decided to offer the solutions on the market as well.

We have repeatedly demonstrated our pioneering role through quantum leaps in engine development. Technological advances such as turbocharging, multi-valve technology and many other milestones are significantly influenced by us. Along the way, we have continuously developed our software.

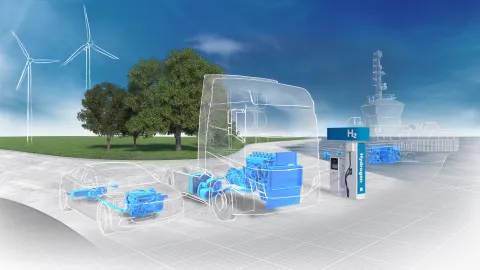

There are currently four main challenges in the development of the ICE:

-

Emissions legislation is becoming stricter

-

Rising fuel prices require more efficient engines

-

New application and usage profiles through hybridization

-

Use of alternative fuels such as hydrogen or biofuels

By using simulation tools, you can overcome all these challenges. Precise Virtual Twins allow you to investigate new operating conditions, different use cases as well as fuels and their effects on your ICE concept with little effort.

For example, analyze the combustion processes of alternative fuels. Look in detail at the effects of other energy densities, the different combustion conditions and, of course, the emission compositions.

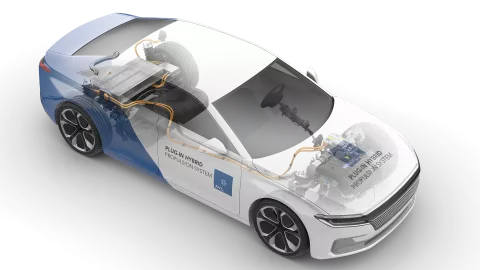

In hybrid operation, the changed operating conditions can stress the engine differently. Of particular interest, therefore, is the engine's durability or how its operating behavior changes under more cold-start conditions. Moreover, you also explore the effects of vibrations and acoustics.

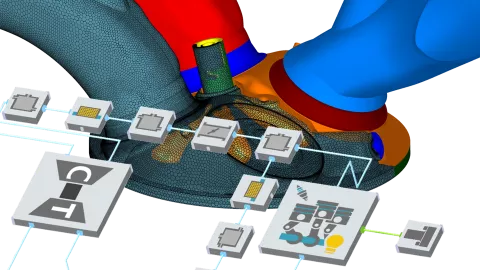

Our tools and methods:

- Can be used throughout the entire development process

- Offer intuitive workflows

- Create exact Virtual Twins

- Provide a reliable basis for decision making based on detailed results

- Incorporate decades of engine development experience

You can use Virtual Twins throughout the development process to look at new systems in detail, e.g. hybrid configurations. Thanks to AVL Simulation Desktop, you can do this on one platform and share and reproduce the results at all times.

- Oliver Knaus, Skill Team Leader Solution Management, AVL List GmbH

As a companion for decades, we all are very familiar with the combustion engine. With hybridization, it is now taking on a new role, which naturally brings new challenges. The introduction of alternative fuels has its own challenges.

Performance, emissions, durability and acoustics now have to be reassessed.

Investigate Performance and Emissions of Combustion Engines Virtually

Emission- and above all CO₂-free mobility is the goal we have set ourselves. Also the IC engine can contribute to this.

Optimizing the ICE Despite Less Development Capacity

The combustion engine will remain with us in various forms for decades to come. Nevertheless, development capacities for the ICE will continue to shrink. Simulation is an alternative to the classic development process. Virtually, the various concepts can be tested quickly.

Advantages of a Development Based on the Virtual Twin

- Applicable throughout the V-development process

- Accurate analysis of emission composition and how to deal with it

- Efficient optimization of efficiency

Efficiently Test Durability and NVH Performance of Combustion Engines Virtually

The combination of the ICE with an electric motor leads to changed operating conditions and thus to new loads. These loads naturally have an influence on the durability and behavior of the engine. The same applies to operating it with alternative fuels.

Advantages of a Development Based on the Virtual Twin

- Applicable throughout the V-development process

- Simple investigation of various operating strategies under different ambient conditions

- Detailed analysis of the NVH behavior of individual components and the entire engine

The mobility revolution is in full swing. This is not just about developing new, more sustainable propulsion systems. Rather, the entire development process is in upheaval - with simulation taking the lead.

Right now, it's important to understand the challenge that each of us - OEMs and suppliers alike - face when it comes to pushing the boundaries of both our design process and our engineers. As the number of different systems grows, departments and team structures are changing. We understand that. At AVL, we go through these processes as well, because we are not just software developers. We are also engineers and therefore users. We implement our knowledge in intuitive workflows, generators, wizards, and evaluations in our software and projects.

We are your global partner in realizing the mobility of the future. A mobility characterized by its minimal impact on the environment. We offer you simulation solutions ranging from component to system analysis. As we are deeply integrated in the development process, our software solutions - tools and projects - enable you to master the challenges of virtualization.

75+

years of experience

in 26

countries worldwide

12,200

employees worldwide

68%

engineers and scientist