In today's world, the responsible use of resources is essential for both regulatory and economic reasons. Energy efficiency and CO₂ reduction have become critical factors for operational performance and cost control.

One of the most effective methods for lowering operational costs is through the conservation and reuse of energy.

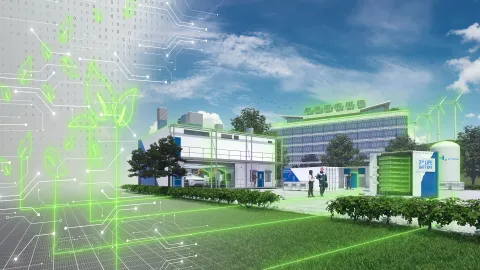

As tech centers become more sophisticated, the power interactions between individual test cells and the overall infrastructure also become more complex. This increasing complexity requires robust processes and advanced tools to accurately understand and manage energy flows within the facility. Our objective is to develop solutions that enhance energy efficiency, optimize resource use, and support efficient and future-ready operations.

Energy Efficient Design

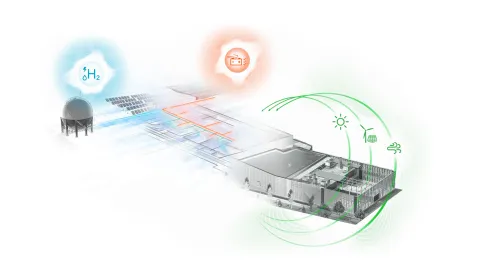

Energy efficiency and total cost of ownership are integral parts of the AVL Test Center Design Service. Based on decades of experience in testing, development, and daily operations, AVL knows that energy consumption and power peaks are crucial factors that need to be considered from the very beginning of a project. We provide support to ensure an optimal design that accounts for both initial investment and operational costs. The first step is understanding the specific application and testing requirements. Right sizing of the equipment and central utilities is essential for an efficient tech center.

Energy Optimization

AVL also offers consultancy services to optimize energy use and reduce operational costs in existing facilities. Whether you are planning to expand your facility, change test cell applications, or lower operational expenses, one of the key points to analyze is how energy is being used and whether the existing power distribution system can meet future demands. Since one solution does not fit all, we will analyze how different energy optimization strategies could work for your project, quantifying the economic impact of each measure in terms of investment and operating costs.

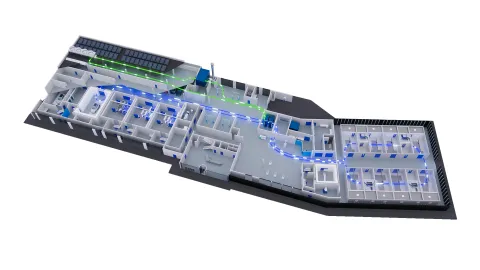

Even with appropriately sized facilities, managing energy consumption and avoiding power peaks can have a significant impact on the operating costs of a test center. AVL EMOS™ monitors energy consumption and testbed operating parameters to detect inefficiencies and identify their causes.

AVL EMOS™ ensures that plant limits are not exceeded during operation by efficiently synchronizing test schedules. This approach helps prevent power peaks, optimizes the power infrastructure, and maintains stable operation in facilities with limited power supply. In addition, it can contribute to lowering power tariffs, further enhancing cost efficiency.

Effective energy management is critical in today's testing world, as it not only helps to reduce carbon emissions and protect the environment, but also leads to cost savings and increased competitiveness for companies and organizations.”

– Eduardo Galindo, Business Development Manager, AVL Iberica S.A.

AVL Tech Center Solutions – Brochure

From Requirements to Reality.

AVL Energy Management Solutions – Whitepaper

Highly Efficient Energy Management for Test Facilities.

AVL EMOS™ – Solution Sheet

Highly Efficient Energy Management.

AVL ATENE™ – Solution Sheet

A comprehensive and customized energy management experience.

Efficient Project Planning: Enable optimized design and infrastructure planning from the earliest project phases.

Informed Investment Decisions: Gain a comprehensive view of utility usage to support strategic investments and future scalability.

Optimized Energy Use: Lower operational costs by tracking energy and power demand in correlation with testbed parameters.

Power Compliance and Safety: Ensure operation stays within facility power limits at all times.

Peak Load Optimization: Effectively reduce peak power demand in both consumption and regeneration.

Our holistic understanding of testing and development forms the basis for an efficient design that meets your current needs while creating future-ready solutions. AVL designs the optimal solution by analyzing and balancing efficiency and total cost of ownership to achieve your project goals.

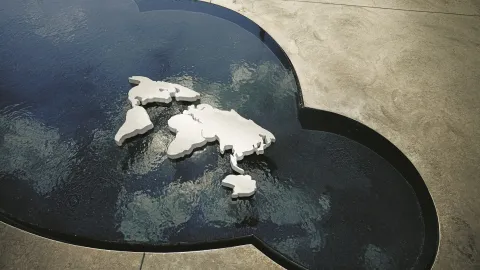

Our global presence ensures consistent and interconnected solutions worldwide.

> 75

testbeds monitored with AVL EMOSTM worldwide

> 20

years of experience in testing facilities SCADA