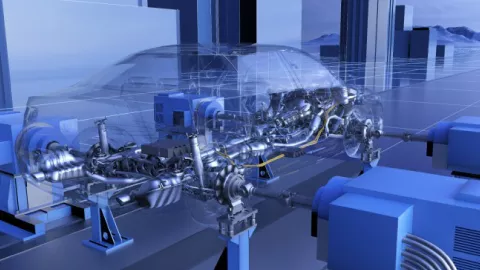

Numerous vehicle and driveline variants, an extensive integration of complex systems, and high requirements for safety, efficiency and comfort mean that shifting development tasks from road to testbeds has become a necessity. While most sub-disciplines already use advanced simulation models in the office only a few find their way into the overall vehicle development process. This is due to the limited capabilities of the testbed but also due to existing department boundaries. Utilizing these models allows for a new testing approach in early development phases, by replacing missing real components with already existing simulation models. Therefore, the simulation capabilities of testbeds are getting more important than ever.

Frontload Tests

Replace missing real components with simulation models in early development phases.

The Power Of Models

Ensure a seamless connection between office simulations and their utilization in the testfield.

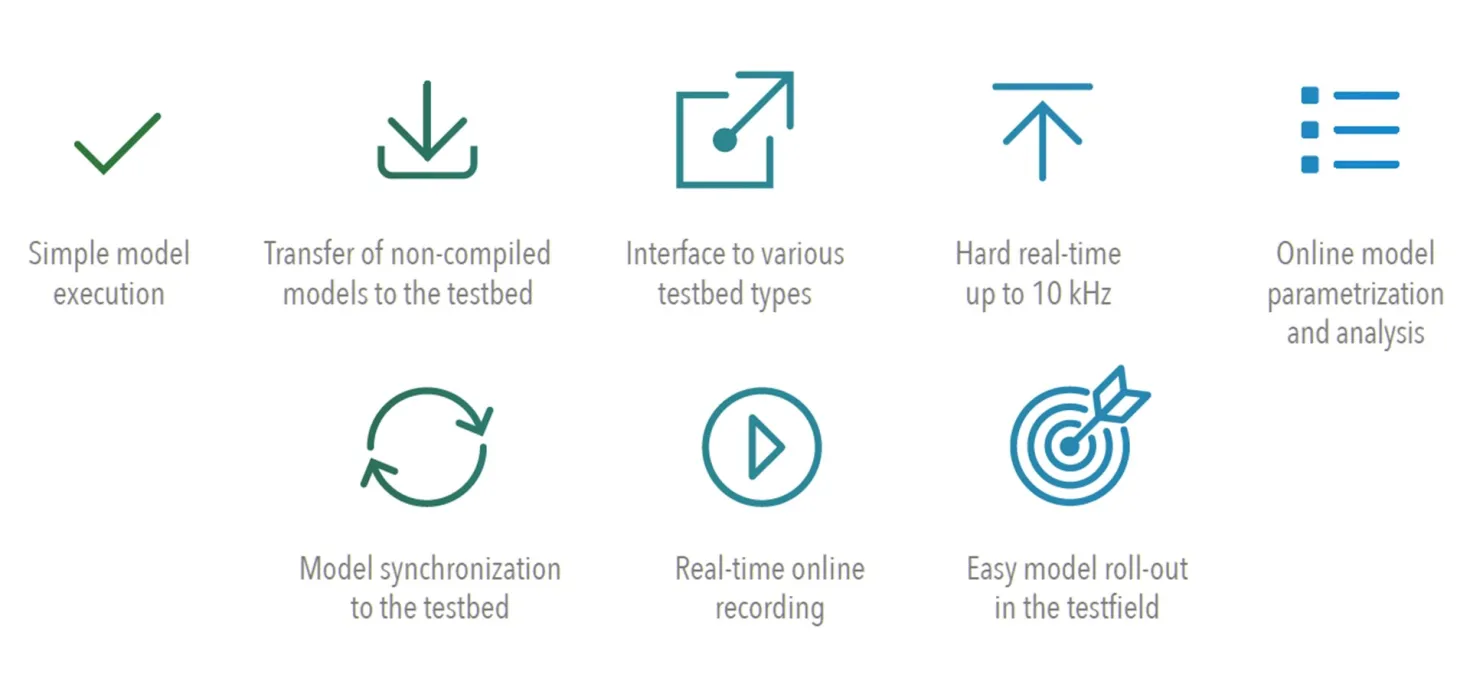

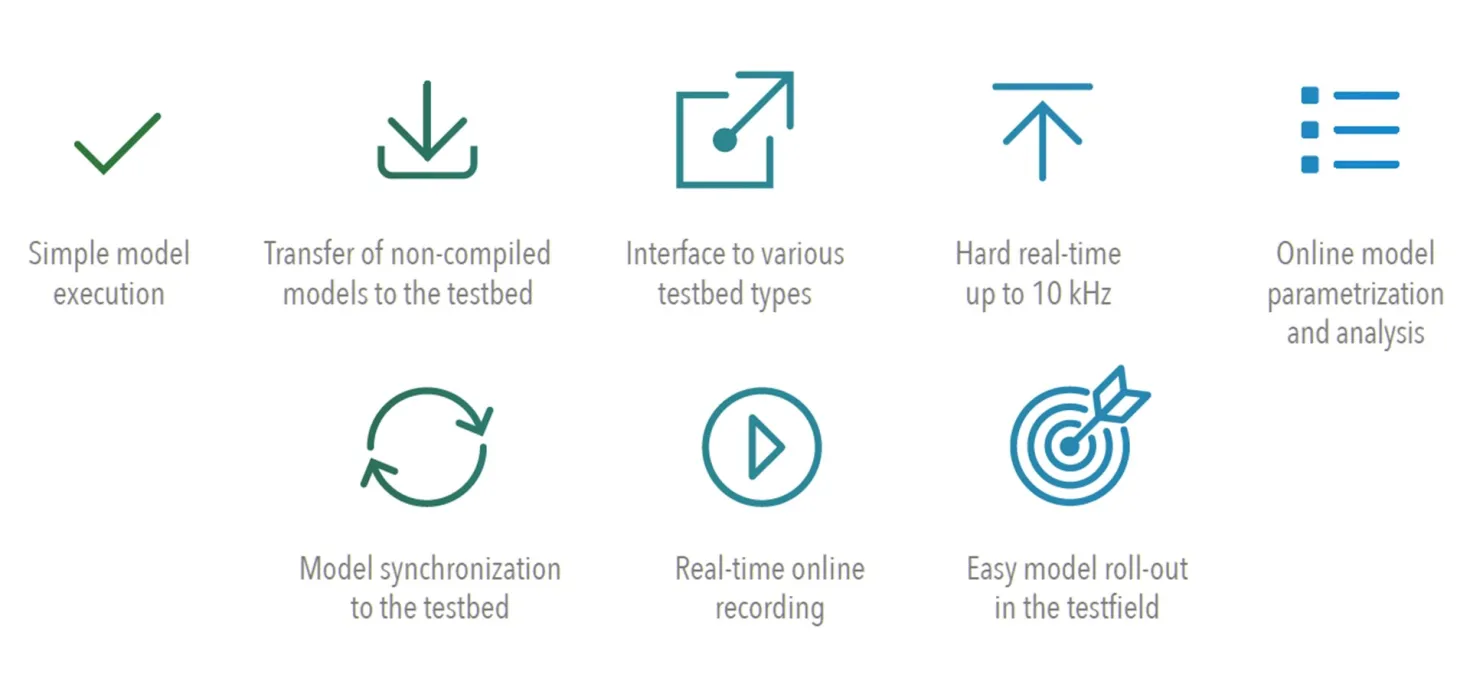

Testbed.CONNECT helps you harness the benefits of model-based testing. As an open platform it facilitates early integration tests by connecting simulation models to the testbed. In alliance with Model.CONNECT™ it opens the testbed to the whole world of office simulation. This prevents long wait times for prototype components and vehicles and allows for quicker and more powerful decision-making throughout the entire development cycle. Testbed.CONNECT offers flexibility that reduces testbed down-times due to task changes to a minimum. Many applications such as, engine start/stop strategy evaluations or electric drivetrains can already be tested on the testbed by using existing in-house simulation models to gain comparable results throughout the development process.

Re-usage

Re-use and continuous improvement of component and system models.

Seamless integration

Easy and stable connection of simulation models to the testbeds.

Future-proof

New testing possibilities using sophisticated simulations even without model compilation.

Model Integration

Testbed.CONNECT allows you to integrate models or model configurations into a testbed system (test environment) and execute them there. The models or model configurations are integrated using an ecp file.

Testbed.CONNECT Explorer

The Testbed.CONNECT Explorer is a graphical user interface for simulation models that visualizes all running real-time models and all blocks contained in them. For each model, all block output ports, all model input and output ports and all mapped parameters can be displayed.

We are constantly working on new solutions. The following might be interesting for you:

Moving steadily into the future: Find out what’s brand new in the field of process simulation on the testbed.