Dynamic calibration plays a pivotal role in the e-drive and e-axle market, guaranteeing top-notch performance, efficiency, and safety for electric vehicles. Each OEM or supplier grapples with their own unique framework requirements, molded by their individual product portfolio and market positioning. Furthermore, different OEMs and suppliers maintain distinct sets of dedicated development tasks and environments.

To adeptly and economically tackle these multifaceted demands, identifying the perfect blend of development environments is absolutely crucial.

Wavy Road Driving

How to effectively manage longitudinal oscillation in the development of e-drives and e-axles through calibration?

Torque Vectoring

What is the most effective way to calibrate vehicle behavior during the use of torque vectoring, while also ensuring comprehensive functional testing?

Traction Control

How to effectively address the challenge of maintaining traction on slippery or partially slippery roads?

Driveability

How to find the best mix of factors that influence the drivability of a vehicle already when testing components?

E-ABS Braking

How to minimize calibration time and ensuring the reproducibility of factors like weather, component temperatures, driver, and maneuver?

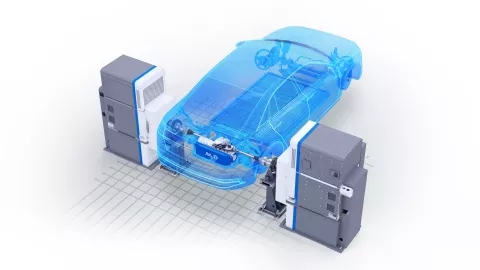

Our dynamic calibration solutions for e-drive and e-axles can be used to shift many development and optimization tasks from vehicle level to component level. This enables you to meet your requirements in terms of performance, cost and flexibility.

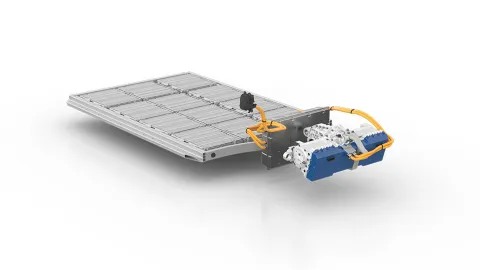

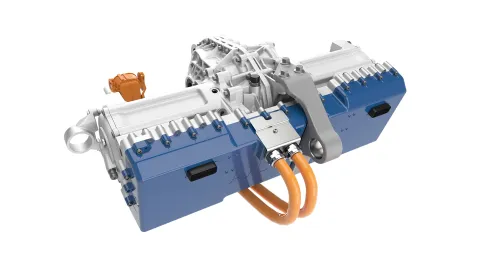

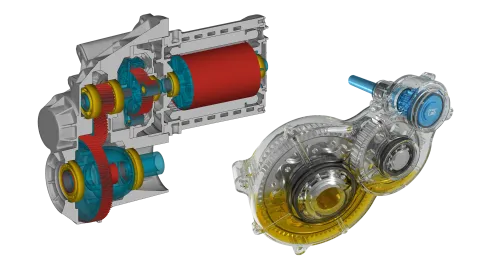

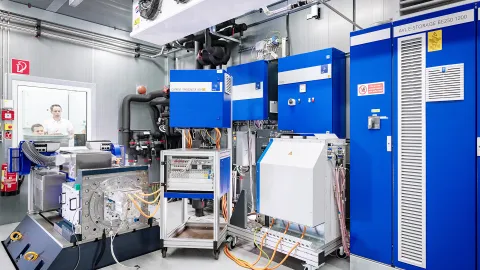

You can couple component testbeds, such as inverter testbed, e-drive testbed, or e-axle testbed, with real-time dynamic vehicle simulation. The flexibility of this solution allows for the integration of additional models when needed, ensuring that every aspect of the development process is thoroughly examined and optimized.

The solution is customized to accommodate your individual needs concerning framework requirements, dedicated development tasks, and available development environments.

Reducing Costs

Decrease the number of vehicle prototypes through efficient frontloading and extensive testing of various conditions.

Making Decisions Earlier

Make informed decisions earlier in the vehicle development process by leveraging simulation.

Frontloading Development Tasks

Shift development tasks in the vehicle to component testbeds by combining accurate simulation and component testing.

Scoping Workshop

We discuss and determine the current situation and framework requirements to identify the most suitable solution.

Proof of Concept

We showcase the methodology to demonstrate capabilities and necessary efforts.

Cost Reduction Calculation and TCO Evaluation

We assess the cost and total cost of ownership both with and without the insights gained from the proof-of-concept project to support your make-or-buy decision.

When you combine physical testing and development with real-time simulation, it creates this amazing chance to make better products faster and at a lower cost. It's like killing two birds with one stone!

– Björn Wultsch, Project Manager IODP, AVL

Related Topics

We are constantly working on new solutions. The following might be interesting for you: