Testing battery prototypes poses significant safety risks, with thermal runaway and fire being among the most serious. Such incidents pose a danger to personnel and can result in extensive damage to testbeds, infrastructure and sensitive equipment.

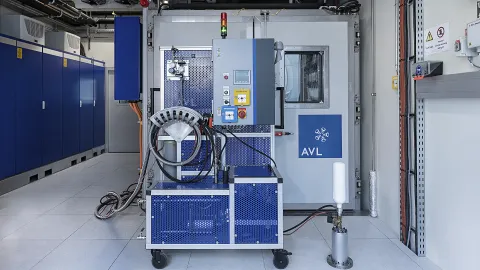

The AVL Stingray™ Testbed offers a purpose-built fire suppression and containment system tailored to high-voltage battery testing. By addressing fires at their source, it ensures maximum safety, protects critical assets, and enables continuous, controlled test operations.

Minimized Damage and Cost Efficiency

Conventional fire suppression methods often lead to extensive damage or even total loss of the testbed. AVL Stingray™ mitigates destruction and reduces financial impact by preserving critical infrastructure.

Advanced Fire Suppression

Stingray goes beyond traditional surface cooling by penetrating the battery pack and suppressing thermal events at their source. This provides fast response, efficient containment and maximum safety for test environments.

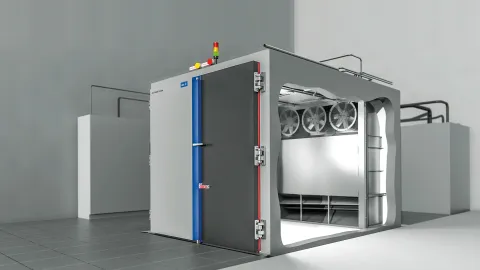

Versatile Integration Across Testbeds

Designed for versatility, our Stingray Testbed can be integrated into a wide range of battery test setups. This makes it an adaptable and scalable solution for different testing applications.

User-Friendly and Efficient Operation

The AVL Stingray™ Testbed is an essential solution for laboratories and test facilities focused on battery safety and risk management. Protect your infrastructure, optimize operational efficiency, and conduct tests with confidence.

The AVL Stingray™ Testbed is designed for rapid and effective fire suppression in battery testing environments. The system comprises two main components:

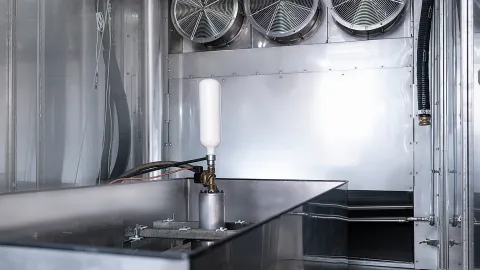

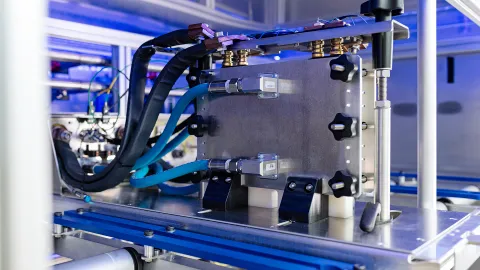

- Punch Unit: Penetrates the battery, enabling direct access for the cooling fluid. Typically positioned inside battery-electric or hybrid vehicles during testing, it can also be used for standalone battery packs. Powered by compressed media, it precisely targets the battery through the vehicle floor.

- Trolley Unit: Houses the control system and technical equipment, ensuring seamless operation and mobility.

Key Features and Benefits

- Direct Battery Penetration: Enables efficient cooling by accessing the battery through the vehicle floor.

- Versatile Application: Suitable for both in-vehicle and external battery testing.

- Fast Installation: Ready for operation in approximately 2 minutes.

- Scalable Solution: Supports up to two punch units simultaneously for larger or multiple battery setups.

- Flexible Cooling Options: Compatible with water or liquid nitrogen for targeted temperature control.

- Adaptive Operation: Offers both manual and automatic activation, ensuring flexibility in emergency situations.

Ensuring maximum safety and efficiency, the Stingray Testbed provides a highly effective cooling solution for battery testing emergencies.

Minimized Downtime & Costs

Reduces testbed damage, allowing testing to resume quickly after an incident

Highly Efficient Fire Suppression

Directly targets the battery fire, optimizing cooling time and liquid usage.

Compact & Scalable Design

Easy to integrate into various test environments, with the option to use two punch units for larger batteries.

Design and Construction

The AVL Stingray™ Testbed consists of two main components: the punch unit, which penetrates the battery to allow direct access for cooling, and the trolley unit, which stores the technical equipment and control system. Its compact and versatile design makes it easy to integrate into various testbeds.

Efficient Cooling

The system instantly goes to the source of the fire. This cuts down the amount of cooling liquid required as well as the cooling time. It also reduces the impact on your testbed.

Multiple Punch Units

The punch unit is typically placed within the battery-electric or hybrid vehicle during testing but can also be mounted directly on external batteries. For larger setups or when testing multiple batteries, you can install up to two punch units simultaneously.

Quick Setup & Flexible Operation

Installation time is approximately just 2 minutes, ensuring that the system is ready for use with minimal delays. The system can be activated either manually or through testbed automation, providing flexible operation while maintaining the highest levels of safety throughout the testing process.

Battery safety on powertrain testbeds has long been an unpredictable risk. With the launch of the AVL Stingray™ Testbed, this danger has now become a challenge that can be managed.”

– Markus Elsner, Product Manager, AVL List GmbH

AVL E-Mobility Testing Solutions – Brochure

From battery to full vehicle, from products, to test systems to whole test facilites – learn how we can support your testing needs.

AVL Stingray™ Testbed – Solution Sheet

Limit potential fire damage with our battery safety system.

AVL Stingray™ One – Solution Sheet

Bringing burning vehicle batteries safely, and quickly under control.