- Expand your testing capabilities

Our solution allows you to quickly convert these spaces into fully functional test stands without the hassle of building pit for the installation of an expensive floor plate.

- Speed up the rigging process

Unit under test (UUT) rigging times negatively affect Total Cost of Ownership (TCO) of testing systems. Therefore, a solution is needed to streamline the upgrade process regarding a chassis dynamometer.

- Optimization with pre-test area

A pre-tested UUT significantly increases the probability of success of the test case, so it is worth paying attention to the pre-test area to optimize test sequences.

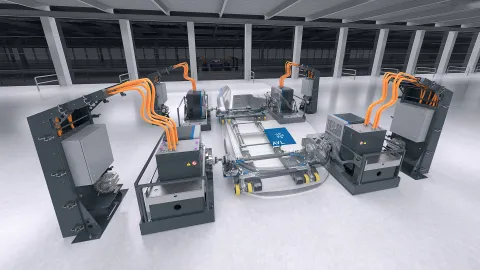

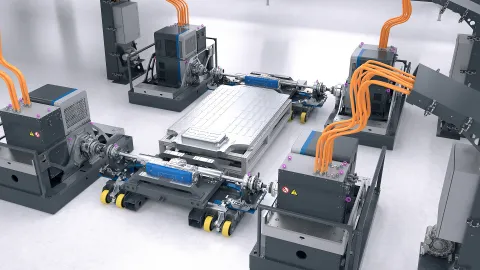

AVL X-Rig™ Pallet

This AVL innovation revolutionizes your testing process in an effective way. It allows you to transfer pre-commissioning tasks from the costly test cell to the economical pre-assembly area. It supports your integration strategy – from single e-axle to complete vehicle in a single test environment. And enables high test cell utilization and fast UUT changeover times, as is common on chassis dynamometer testbeds.

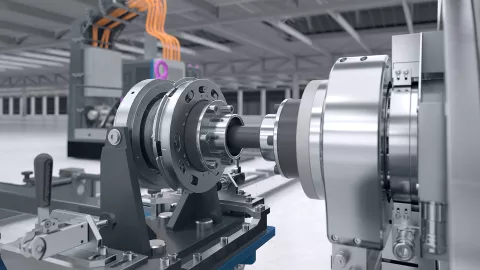

AVL X-Rig™ Coupling

With our fast-coupling CV shaft, getting ready for testing is now possible in even shorter time, improving overall efficiency. The solution includes a bayonet lock, which allows for quick set-up of the UUT and ensures a secure, reliable connection to the load system. For added convenience, a mounting aid is optionally available, and a fully automatic solution can be implemented for even faster, hands-free operation.

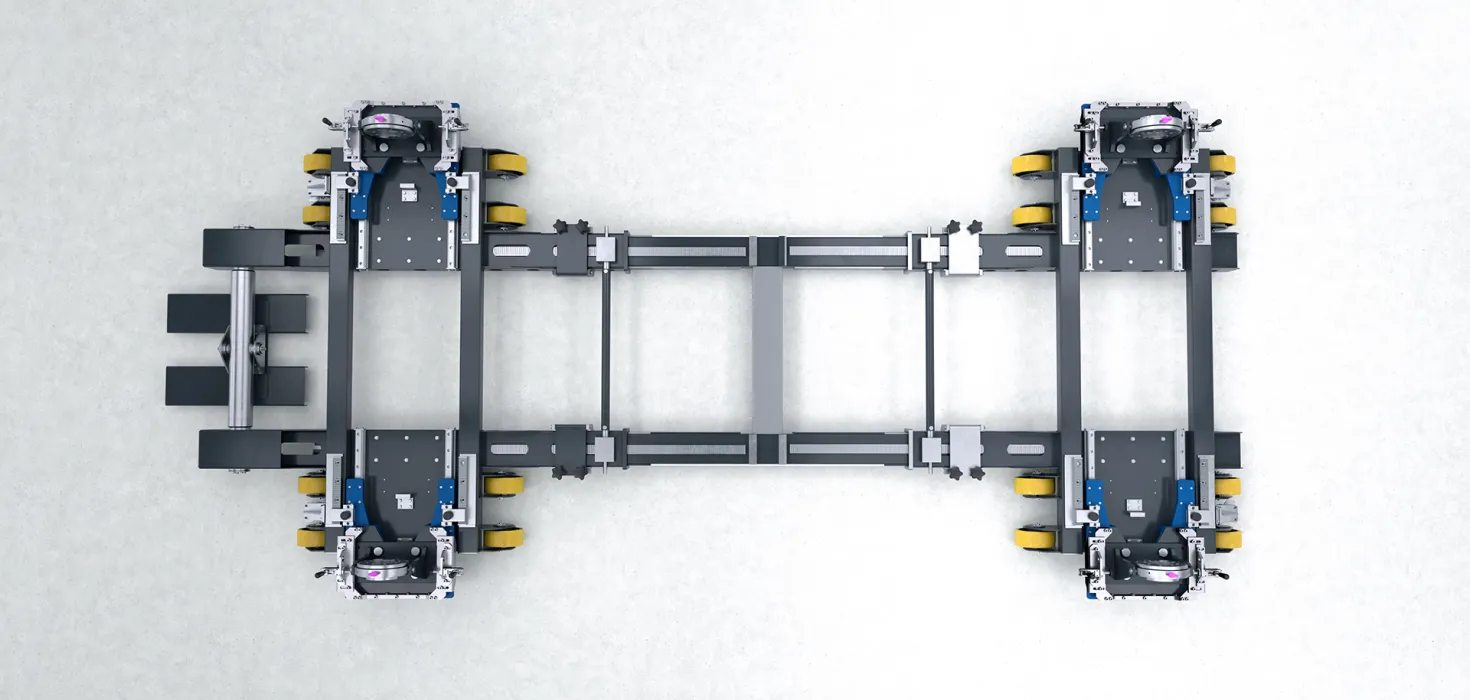

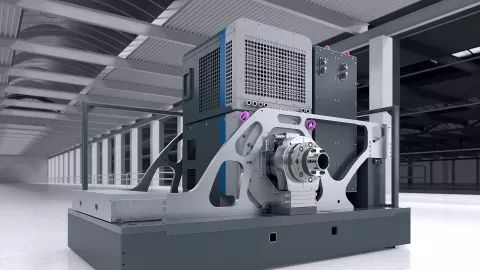

AVL X-Rig™ Frame

These customizable frames allow for the proper positioning of the dynamometers. Depending on your test requirements, you can choose the most suitable dynamometer and inverter combination from our portfolio. With this solution there is no base plate required, which is realized via the vibration decoupling frame. Manual positioning of the dynamometer is included but automatical positioning can be implemented as well.

With the AVL X-Rig System we enable our customers to operate a 4WD powertrain testbed in the same way as a chassis dyno – for maximum throughput, highest efficiency, and reduced cost.”

– Georg Seewald, Lead Architect X-Rig™ System, AVL List GmbH

The most common method of suppressing a battery fire or thermal runaway incident is to flood the testbed with enormous amounts of water. This often leads to the damage or destruction of electrical equipment, test cell environment and is therefore far from ideal.

We have developed a unique battery safety system to combat this issue. This revolutionary system instantly addresses the source of the fire and cuts down both the amount of cooling liquid required as well as the cooling time.

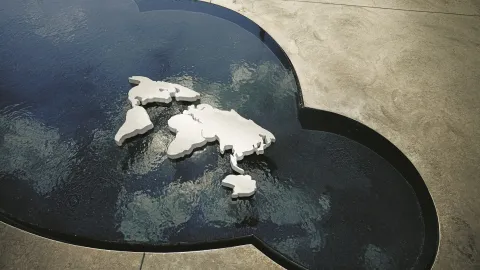

AVL’s comprehensive worldwide network of experts allows best customer vicinity, ensuring consistent and connecting testing fields globally. Wherever your R&D challenges take you, we are always close at hand, ready to provide the service you need.

> 70

years of experience

> 5000

employees worldwide for testing solutions

> 30

countries covered by the global network

> 7000

testbeds installed worldwide

> 80

turnkey projects