The demand for testing is highly dynamic, often requiring the urgent expansion of test capacity to meet product development deadlines and market release dates. However, access to capital represents a significant limiting factor. There is a growing reluctance among companies to commit substantial financial resources to long-term investments, particularly when there is no immediate return on investment.

Traditional brick-and-mortar test facilities require extensive time for planning, approval, and construction. The process can take several years, from identifying the need for additional capacity to the point of facility operation. This delay not only extends the time to market but also ties up capital, which limits a company's financial flexibility and responsiveness to market changes.

Extensive Approval Process

Getting the necessary approval for starting construction of new brick-and-mortar test facilities takes a long time.

Low Degree of Parallelization

While the approval process is running, many of the other activities cannot start, increasing the project time.

Commission-ing First at the End

With all coming together first at the construction site, the commissioning can first happen at the end of the project – with potential unwanted surprises.

Low Flexibility to Add Further Test Capacity

Additional space must be reserved in the facility hosting the test system if a later extension is desired.

Challenging Coordination of Suppliers

Building up a new test facility requires coordination of all involved suppliers, requiring experienced test facility project managers.

Lack of Mobility

A conventional test facility is stationary and cannot be moved to another location if later necessary.

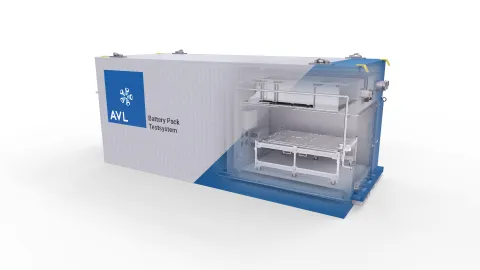

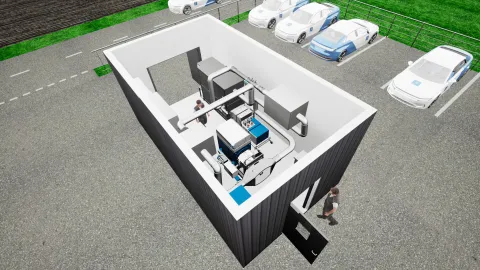

Our test systems are available in tech center modules that are quickly up and running. The solution consists of a fully integrated test system in a containerized format. The module can operate independently to a high degree, only requiring a flat surface to be located on and the necessary external power and media connections.

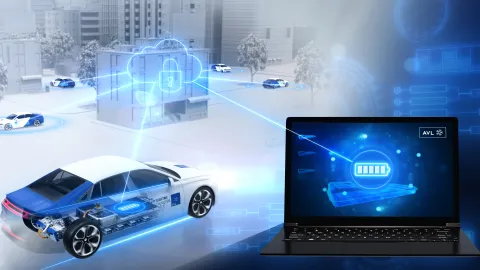

Through standardization, supply chain management and preemptive engineering efforts, we have significantly reduced the time from order to start of operation at the customer site. This provides our customers with optimal flexibility to respond to changing needs and limits their capital commitment.

AVL has more than 20 years of experience in modular test solutions and has delivered more than 400 test systems worldwide.

Time Reduction

The module manufacturing process starts in parallel with the acquisition of official permits, enabling site preparation to be ready on delivery.

Low Site Requirements

The module only requires an industrial floor, electrical power and media connections to be operational.

Ready to Use

Designed for fast deployment, the module is pre-assembled at the AVL workshop, ensuring a short ramp-up time.

Minimum Capital Commitment

The shortened delivery time not only accelerates project progress but also gives decision-makers the flexibility of a late-stage investment.

Complete Solution Out of One Hand

A single point of contact for planning, manufacturing and supplier coordination with proven and tested compatibility of all components.

With our Tech Center Modules, we offer cost effective solutions that are up and running in a very short time. It is particularly valuable for customers who needs to act fast on changings needs and where the requirements on the installation location must be kept to a minimum.”

– Stefan Sohar, Solution Engineer, AVL List GmbH

AVL Tech Center Solutions – Brochure

From Requirements to Reality.

AVL Tech Center Solutions – Whitepaper

Beyond the Test System: The True Scope of Investment.

AVL Tech Center Modules – Whitepaper

Adding test capacity has never been easier.

Tech Center Module – AVL Battery Pack TS™ – Solution Sheet

The fast track to battery testing excellence.

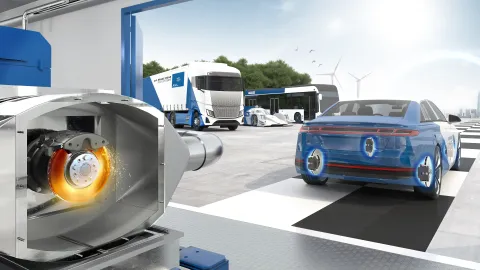

Tech Center Module – AVL Brake Emission TS™ – Solution Sheet

The fast Lane to ramp up brake emission testing.

Tech Center Module – AVL E-Axle TS™ – Solution Sheet

The fast lane to ramp up e-axle testing.

Tech Center Modules - Fuel Cell System Testbed

The fast track to fuel cell testing excellence.

In most cases, a building permit is required to install and operate a tech center module. However, the permitting process for modular solutions is typically faster than for conventional testbeds. This efficiency arises from the clearly defined scope of modular projects, similar to that of a product. A significant advantage is that construction can begin while the permitting is still in progress, saving valuable time and often reducing the project timeline by 3 to 5 months. Additionally, when tech center modules are installed within existing buildings, additional permits may not be required, depending on local regulations.

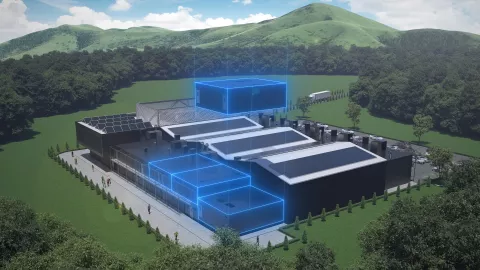

Tech center modules are engineered for both indoor and outdoor applications, meeting all essential requirements such as air conditioning, humidity control, noise reduction, fire safety, and durability. These versatile modules can be combined into larger configurations or stacked up to three stories high, allowing for flexible space utilization. Furthermore, local building regulations can be satisfied by incorporating a roof or facade, ensuring that the modules blend seamlessly with their surroundings.

For optimal performance, tech center modules must be installed on a leveled and paved surface, such as a pad or screw foundation. Depending on the specific application of the module, essential utilities - including electrical power, compressed air, chilled water, demineralized water, and wastewater - must be provided. If these services are not available on-site, an optional utility module can be supplied to meet the necessary requirements.

Unlike traditional shipping containers, tech center modules are constructed from high-quality, container-like structures specifically designed for easy transport and assembly at their destination. These modular units adhere to stringent standards for insulation, safety, and noise and vibration control. Inside, the seamless design provides users with a high-performance environment comparable to that of a traditional facility.

Tech center modules are available with UL or CE certification, depending on the region and specific customer requirements. These certifications guarantee compliance with safety, health, and environmental standards, whether in North America (UL) or the European Union (CE). This ensures that tech center modules meet the necessary regulations and provide a reliable and secure solution for various applications.

Each tech center module typically measures up to 4.5 meters in width, 15 meters in length, and 2.9 meters in height, with a total weight ranging from 20 to 25 tons, including all technical equipment. It is important to note that specific dimensions and weights may vary depending on the application. For more detailed information, please refer to the solution sheets for each configuration.