Technological progress and the pursuit of new innovations make systems more and more complex. But there is no extra time available for development. For this reason, engineers are under pressure to confirm concepts as early as possible.

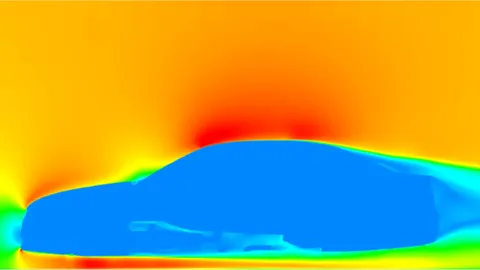

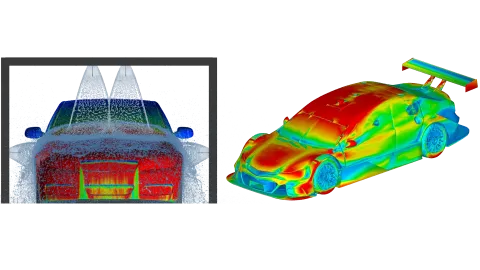

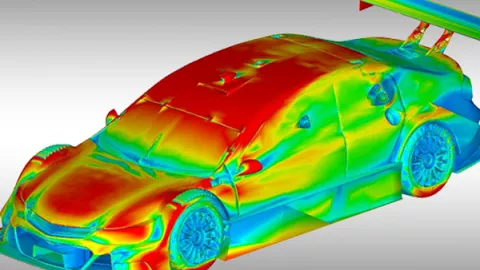

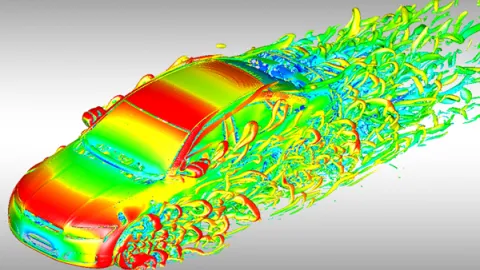

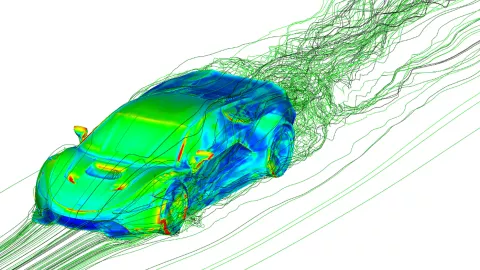

Dealing with complex geometries, large computational meshes, and the simulation of various physical phenomena are only a small part of the challenges that have to be overcome in CFD. In doing so, the user must not compromise between accuracy and speed.

Cost Pressure

Physical tests require prototypes, are time and personnel intensive and thus costly

Speed

Development time is not always balanced with development effort

Complexity

Increasing number of interacting and thus interdependent components

Accuracy vs. Speed

Optimization of one side is often at the expense of the other

Advanced Simulation

The creation of CFD simulation models is complex and can therefore be very time-consuming

Safety

Strict requirements for product functionality, quality, and safety must be met

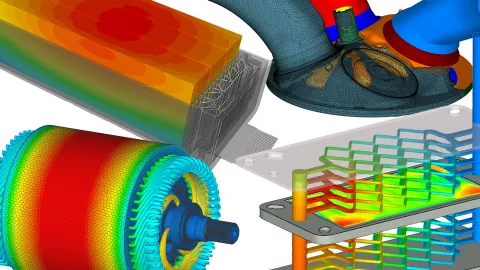

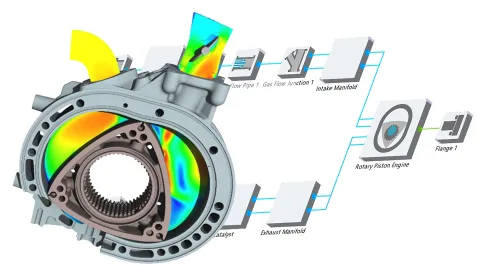

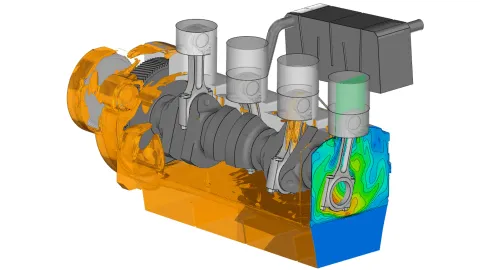

FIRE M has unique preprocessing, solver and post-processing capabilities.

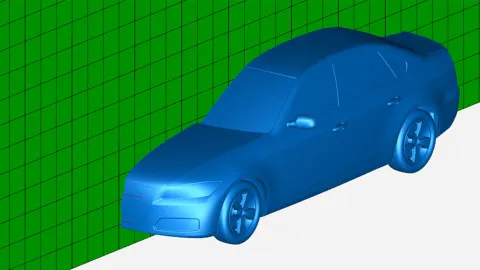

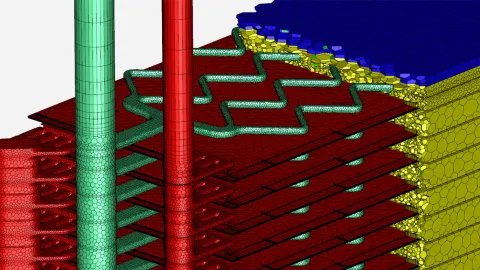

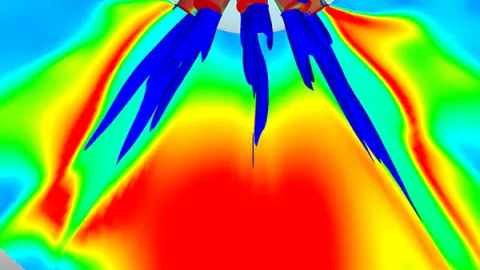

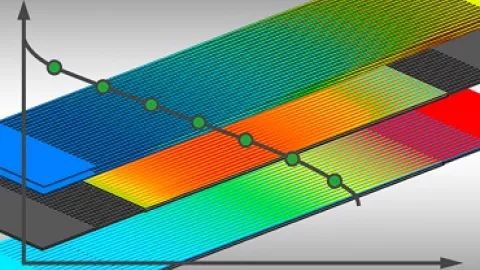

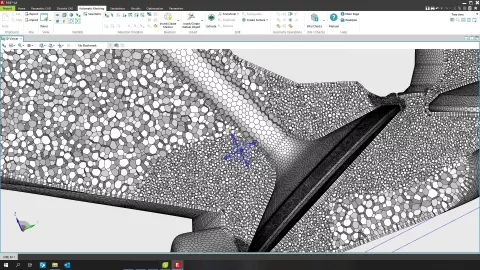

The software can handle any computational mesh, from hexahedral to polyhedral cells, including meshes with arbitrary interfaces. By combining basic finite volume technology for polyhedral meshes with the Immersed Boundary method, you can solve applications with any geometric complexity, as well as body and mesh motions. We call this unique approach the Embedded Body Method.

Solution apps, introduced with Release 2021 R2, provide guided workflows and templates that let you create complex applications in minutes.

FIRE M provides state-of-the-art turbulence modeling that accounts for the complexity of real flows.

The grid-independent modeling of heat transfer enables the accurate calculation of single-phase and multiphase flows, heat transfer between arbitrary fluid and solid regions, and temperatures in structures.

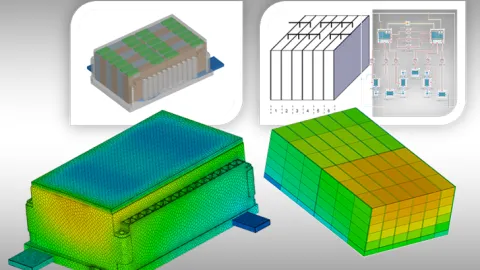

In addition, the software also supports the calculation of electromagnetic fields and the electrothermal behavior of batteries.

Easy to Use

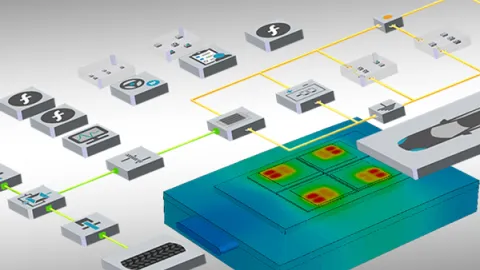

Guided workflows and templates make it easy for users to work with the software. The AVL Simulation Desktop (SDT) provides a platform for data exchange within and outside your team as well as with other tools.

Data as the Basis for Development

Precise meshing and calculations deliver the most accurate results. This lets you make data-based decisions.

Work Efficiently

With FIRE M you can simulate multiple areas at the same time. Simultaneous simulation.

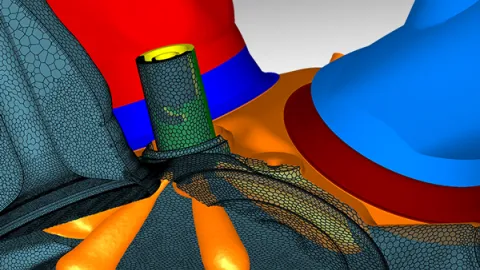

Embedded Body

Mesh setup in CFD is a challenging task. FIRE M therefore now integrates the "Embedded Body" into the standard finite volume method.

This immersed boundary approach simplifies the handling of geometrically complex bodies at the fluid-solid interface in terms of discretization of fluxes, boundary conditions, rate of change, gradient calculations, etc. The handling of the embedded body is extremely simple as it basically involves only two steps.

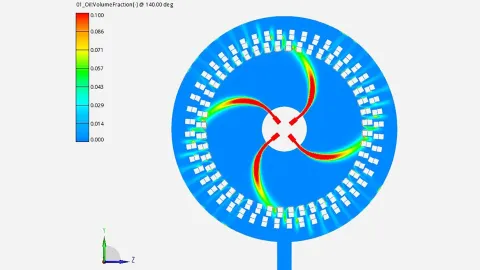

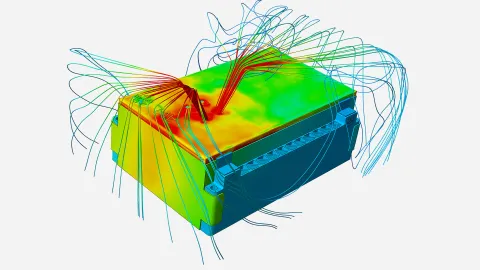

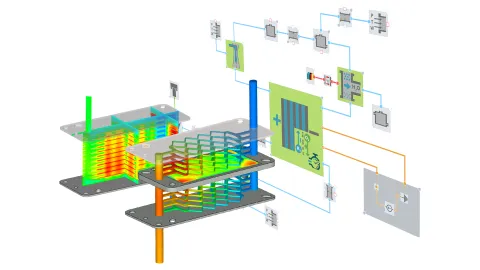

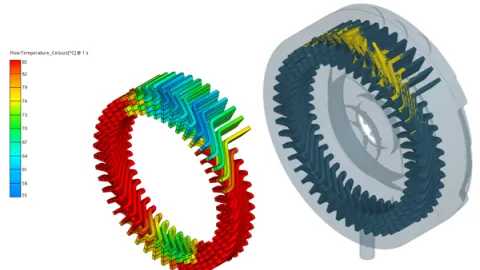

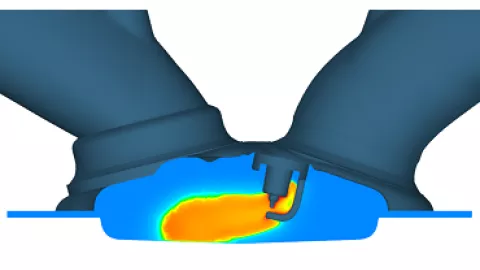

E-Motor Cooling App

Effective cooling systems are critical to the life of an electric motor. The Solution App offered in FIRE M, contains a guided workflow for solving oil spray cooling tasks.

Starting with CAD setup, mesh preparation and model setup, you are guided through the start of simulation to post-processing. This not only simplifies the entire process, but also speeds it up.

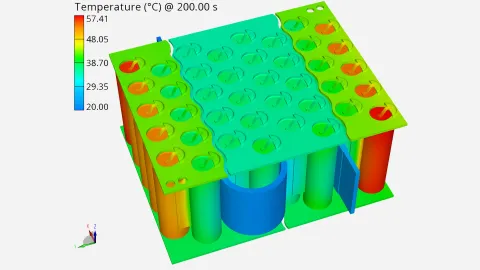

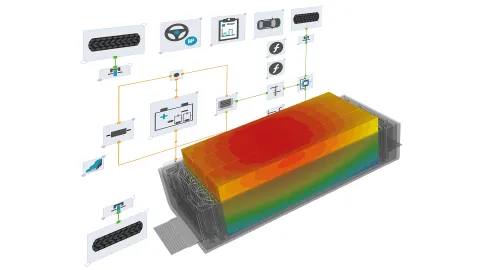

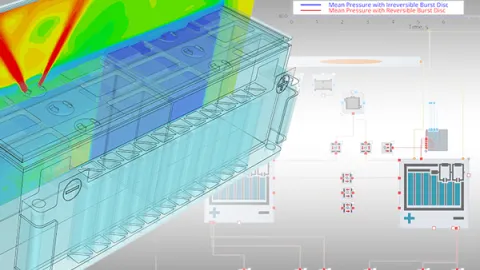

Thermal Runaway Simulation

To ensure the safety of battery systems, it is necessary to know when thermal runaway can occur in cells and how quickly it spreads to neighboring cells.

FIRE M provides the ability to analyze thermal runaway and propagation in detail under a variety of conditions. You can use the Virtual Twins to repeat the tests in exactly the same way and as many times as needed. In doing so, you are supported by the Battery Thermal Runaway app.

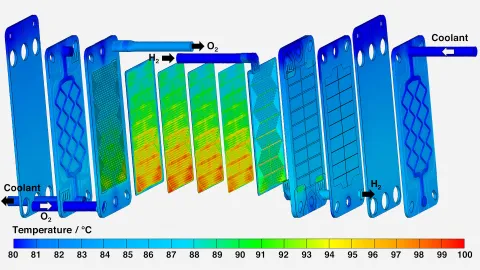

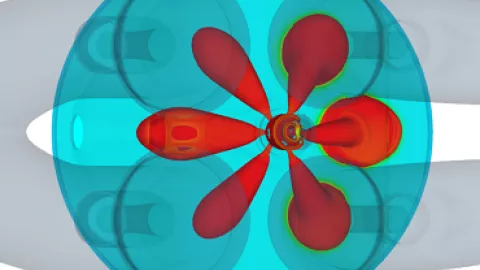

Fuel Cell Degradation Modeling

For fuel cells, too, the goal is to develop safe and long-lasting cells with constant performance. This requires detailed knowledge of cell aging and its causes in order to avoid potentially harmful operating conditions.

For PEMFC, FIRE M offers the possibility to study the following chemical degradation mechanisms:

- Carbon corrosion/carbon oxidation/platinum oxidation

- Platinum dissolution and repositioning

- Particle detachment and agglomeration

- Ionomer degradation

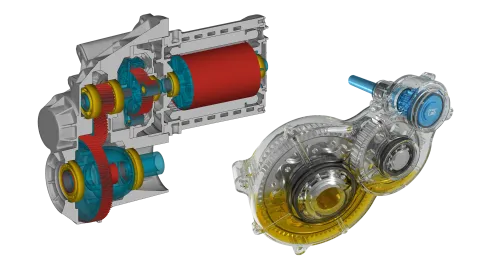

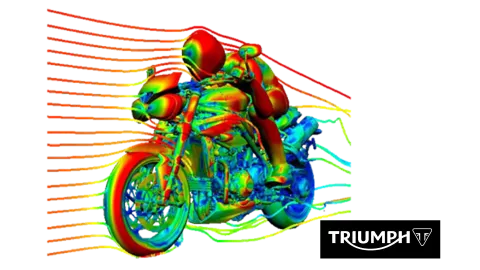

AVL EXCITE™ and AVL FIRE™ M are an integral part of our virtualization strategy, allowing design optimization early in the development cycle. AVL’s simulation solutions help us maintain our position as a manufacturer of class-leading motorcycles.

– Specialist Team Leader, Triumph Motorcycles Ltd.

AVL White Paper – Process-Safe 3D CFD Simulation of Internal Combustion Engines

Download this White Paper and find out how our 3D CFD simulation solution helps engineers realize the ICE’s optimization potential towards zero impact emission and CO2.

AVL White Paper – Reducing GDI Engine Soot Emission by Minimizing Nozzle Tip Wetting

Download our white paper and learn how to reduce GDI engine soot emission by minimizing nozzle tip wetting.

AVL White Paper – Exhaust System Development Through Virtual Prototyping

Download our white paper and find out how we support OEMs in their strive to reduce emissions below the strict legal limits.

AVL White Paper – Using CFD for Quenching Optimization

Download our white paper and learn more about the predictive simulation approach for the optimization of heat treatment processes including air quenching, immersion or water quenching and quenching of steel components.

AVL White Paper – Virtual Fuel Cell Performance and Lifetime Optimization - From Component to Vehicle Level

Download our white paper to find out how AVL eSUITE™ helps OEMs and suppliers get the best performance and longest lifespan from this clean power source.

AVL Customer Case Study - System Simulation in BEV Development at EDAG

For battery electric vehicles (BEV), the high-voltage storage unit is the crucial component in terms of performance, efficiency and range. To optimize these attributes extensive investigations are required. Both in the overall vehicle context and under different, sometimes extreme boundary conditions.

AVL White Paper - Efficient Battery Thermal Management in BEVs

In this paper we present a numerical approach using AVL CRUISE™ M to design a snake shaped cooling channel for cylindrical cells.