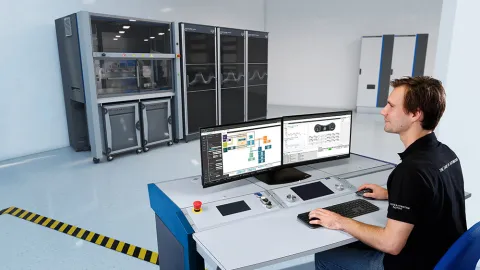

The AVL Active Load Cabinet (ALC) is an active power test device which can be used to perform high-voltage functional tests of inverters (UUT). Thanks to its open communication interfaces, the ALC can be easily integrated into a lab or test setup.

The ALC enables robust inverter functional tests within short test times and according to the UUT’s voltage and power requirements. These functional tests enable a parallel development, independently from the UUT’s software, and provide the opportunity to detect failures at an early stage – before hardware and software integration.

Inverter Hardware Testing

Testing pure hardware while no serial software is available.

Parallel Development

Saving time and money due to split hardware and software development tasks.

Early Failure Detection

Detecting malfunctions in an early stage of the inverter hardware development.

The AVL Active Load Cabinet provides the following operating modes:

- Four-quadrant mode

- R-L mode

- One-phase current source mode

The four-quadrant mode of the ALC enables the testing of the UUT within all four quadrants (speed/torque plane), meaning motor and generator operation. In R-L mode, the ALC acts as an adjustable ohmic inductive load. Due to active power, the testing of the UUT‘s power electronics is enabled under more realistic conditions.

Optionally, the ALC can be used as a one-phase current source to e.g. calibrate the UUT internal sensors or to test the connectors.

Technical Data

| UUT DC Voltage (in VDC) |

300 - 1,000 |

| Phase current (nominal A rms) |

280 or 560 |

| Phase current (maximal A rms) |

400 or 800 for 34s (up to 900 V) |

| Power AC in kW | Depending on the operating point and UUT |

| Fundamental frequency Hz |

up to 1,000 |

| Interfaces | Automation system: EtherCAT, Ethernet XCPonEthernet; Safety system: Profinet |

| Rotor positions sensor options |

Digital encoder sensor emulator, active magnetic sensor emulator, resolver sensor emulator |

Fast UUT commissioning

enabled by the easy test setup capability: only 4 parameters must be defined to start the testing process.

Easy and fast adjustment

of several parameters: R and L can be parametrized via mouse click during operation.

Minimum facility requirements

only 30kW AC connection for power and water connection for cooling is needed.

Wide range of applications

thanks to additional options like one-phase current source and four-quadrant mode operation.

AVL Active Load Cabinet™ – Solution Sheet

Perform a wide range of high-voltage functional

tests for R&D applications.

AVL Inverter TS™ – Solution Sheet

Enable the validation of the inverter and prepare its integration into the electrified powertrain.

AVL E-Mobility Testing Solutions – Brochure

From battery to full vehicle, from products, to test systems to whole test facilites – learn how we can support your testing needs.